Small-pore-diameter long-distance optical compatible vacuum sample cavity

A long-distance, small-aperture technology, applied in the field of material optical property measurement system, to achieve the effect of simple and effective design, easy implementation, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

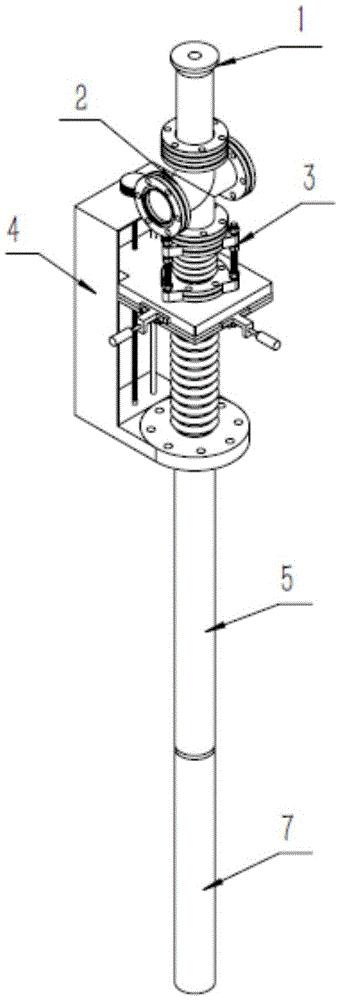

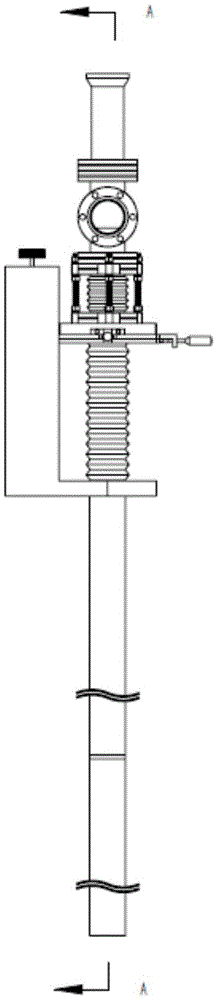

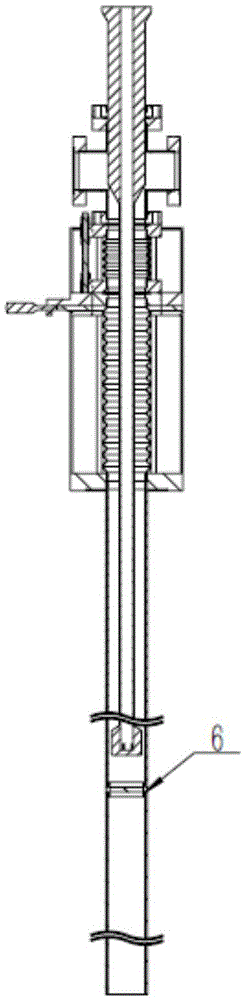

[0026] As shown in Figure 1, a small-aperture long-distance optically compatible vacuum sample chamber includes a low-temperature sample rod 1, a four-channel connection device 2, an ultra-high vacuum angle adjustable device 3, an ultra-high vacuum XYZ three-dimensional displacement platform 4, an upper Cavity 5 , optical window 6 and window protection cavity 7 . details as follows:

[0027] The low-temperature sample rod 1 is vacuum-tightly connected with the four-channel connection device 2, the four-channel connection device 2 is connected with the ultra-high vacuum angle adjustable device 3, and the ultra-high vacuum angle adjustable device 3 is vacuum-tightly connected with the ultra-high vacuum XYZ three-dimensional displacement platform 4 Sealed connection, the ultra-high vacuum XYZ three-dimensional displacement platform 4 is vacuum-tightly connected to the upper chamber 5 , the upper chamber 5 is vacuum-tightly connected to the optical window 6 , and the optical windo...

Embodiment 2

[0035] As shown in Figure 2, a small-aperture long-distance optically compatible vacuum sample chamber includes a low-temperature sample rod 1, a four-channel connection device 2, an ultra-high vacuum angle adjustable device 3, an ultra-high vacuum XYZ three-dimensional displacement platform 4, an upper A cavity 5, an optical window 6, a window protection cavity 7 and a window protection air tube 8 are formed. The inner wall of the window protection cavity 7 is equipped with three protective gas inlet thin tubes 8, which are evenly distributed on the inner surface of the cavity, and the tops are not in contact with the window. details as follows:

[0036] In this embodiment, the installation method of the low-temperature sample rod 1, the four-channel connection device 2, the ultra-high vacuum angle adjustable device 3, the ultra-high vacuum XYZ three-dimensional displacement platform 4, the upper cavity 5, the optical window 6 and the window protection cavity 7 Same as Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com