Single skeleton for winding multiple optical fibers, and application method of single skeleton

An optical fiber and skeleton technology, which is applied in the field of multi-segment optical fiber loop coiling, can solve the problems that restrict the wide use of optical fiber delay loops, deteriorate the performance of optical fiber delay loops, and cannot coil multi-segment optical fibers, achieve good temperature environment adaptability, and improve the temperature environment. Adaptability, the effect of improving coiling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

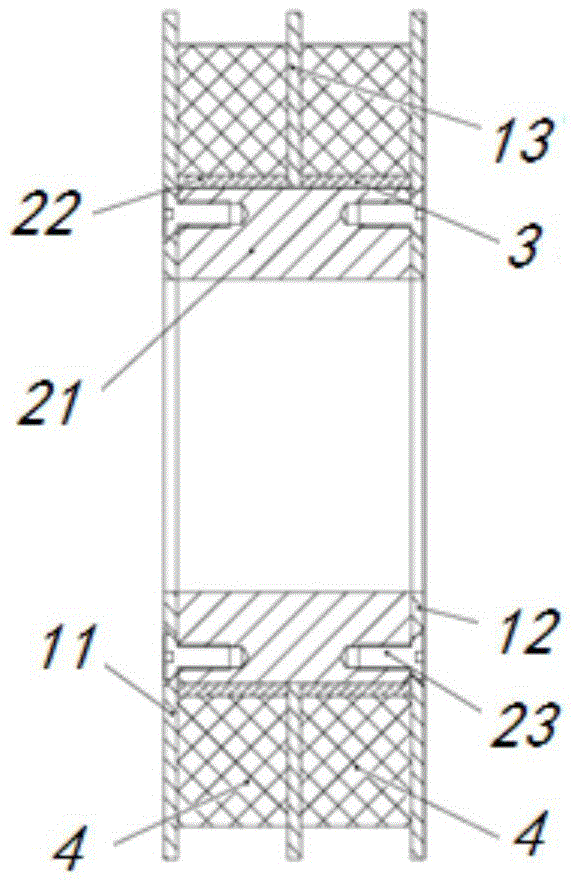

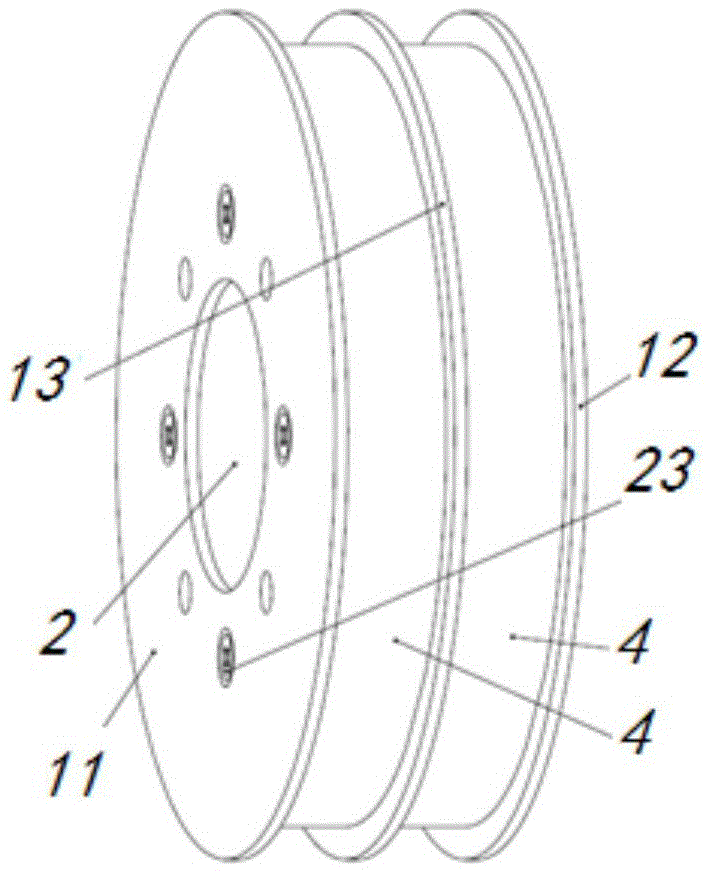

[0036] Such as figure 1 and figure 2 As shown, a single frame for coiling multiple segments of optical fibers in Embodiment 1 includes a baffle plate 1 , a winding shaft 2 and a supporting sleeve 3 .

[0037] The baffles in Embodiment 1 include: a first outer baffle 11 , a second outer baffle 12 and an intermediate baffle 13 located between the first outer baffle 11 and the second outer baffle 12 .

[0038] This embodiment 1 takes an intermediate baffle 13 as an example to illustrate the structure of the single skeleton in the present invention, so as to facilitate the understanding of the technology in the present invention. According to the number of coils of the optical fiber ring 4, multiple intermediate baffles can be added 13 to coil a plurality of optical fiber rings 4.

[0039] The separate structure of the winding shaft 2 in the first embodiment is mainly manifested in that one end surface of the winding shaft 2 and the inner side of the first outer baffle plate 11...

Embodiment 2

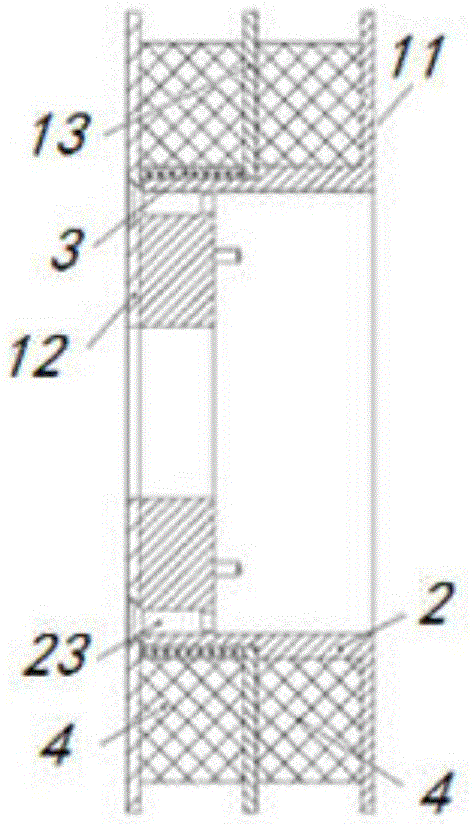

[0042] Such as image 3 and Figure 4 As shown, a single frame for coiling multiple segments of optical fibers in Embodiment 2 includes a baffle 1 , a winding shaft 2 and a supporting sleeve 3 .

[0043] The baffles in the second embodiment include: a first outer baffle 11 , a second outer baffle 12 and an intermediate baffle 13 located between the first outer baffle 11 and the second outer baffle 12 .

[0044] This embodiment 2 takes an intermediate baffle 13 as an example to illustrate the structure of the single skeleton in the present invention, so as to facilitate the understanding of the technology in the present invention. According to the number of coils of the optical fiber ring 4, multiple intermediate baffles can be added 13 to coil a plurality of optical fiber rings 4.

[0045] The integral structure of the winding shaft 2 in the second embodiment is mainly manifested in that one end surface of the winding shaft 2 and the inner side of the first outer baffle 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com