Hook type connecting and unlocking device

An unlocking device and unlocking technology, which is applied to projectiles, self-propelled projectiles, offensive equipment, etc., can solve the problem that the belt-type separation device has a large separation impact, is not conducive to improving the reliability of the launch vehicle, and is difficult to control the uniformity of the preload force distribution. and other problems, to achieve the effect of improving separation reliability, effective connection method, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

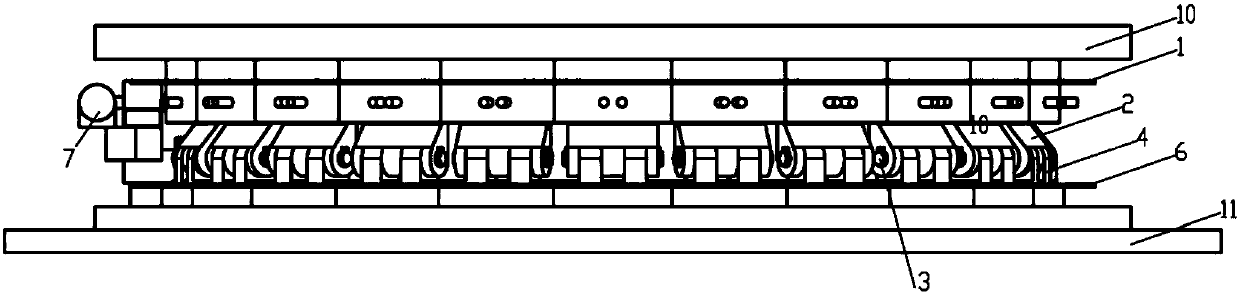

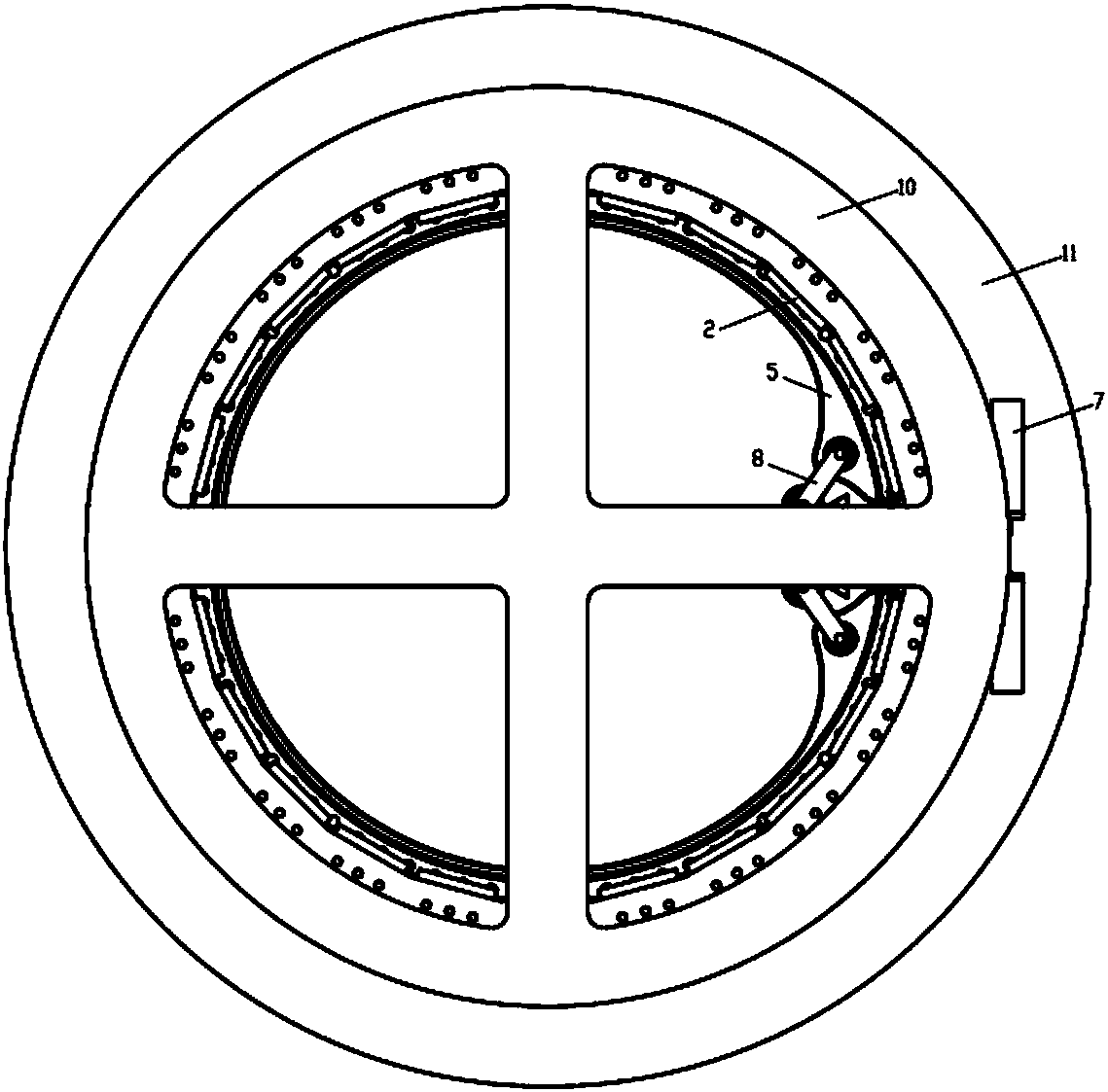

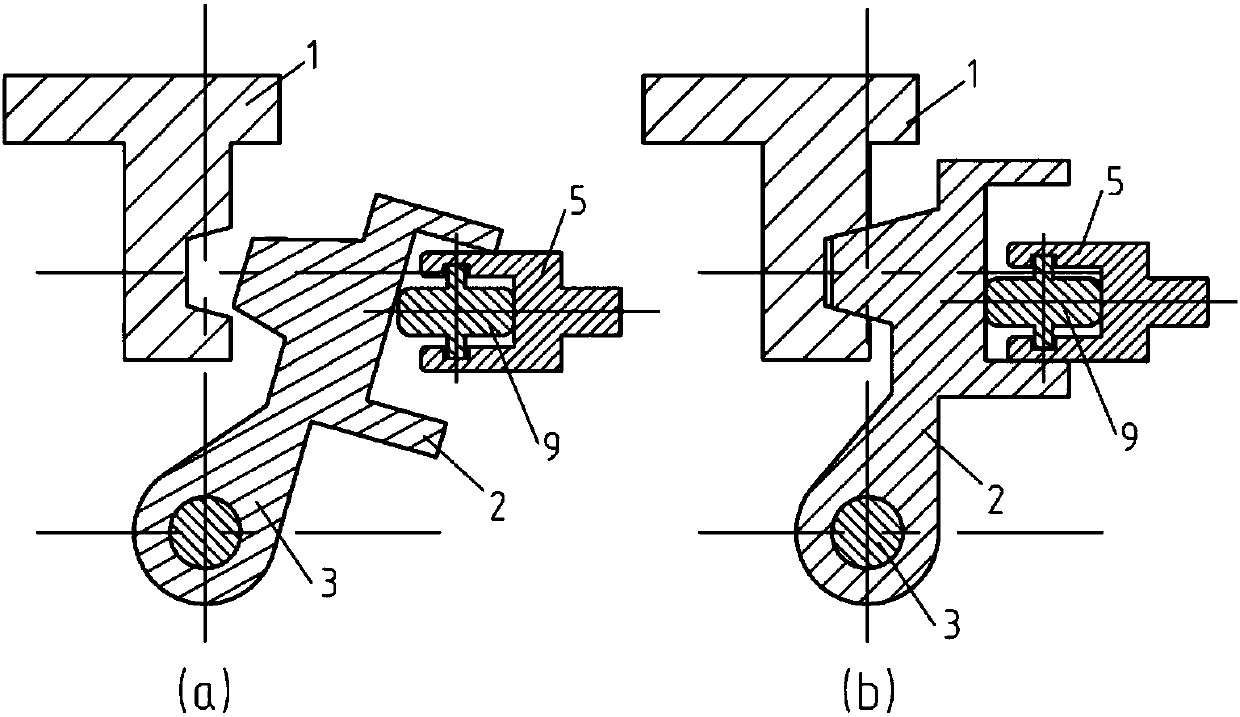

[0036] The purpose of the present invention is to disclose a separation method between stages and even satellites that can meet the separation requirements of space vehicles. The present invention will be described in detail below in conjunction with the accompanying drawings and examples. Such as figure 1 As shown, the structure of the hook-type connection and unlocking device mainly includes an upper frame 1, a rotating block 2, a roller 3, a base 4, an inner support ring 5, a lower frame 6, a motor assembly 7, a connecting rod 8 and a roller 9.

[0037] Wherein the upper end frame 1 is fixed together with the structural member 10 through the upper butt joint fastener, the lower end frame 6 is fixed together with the structural member 11 through the lower butt joint fastener, and the rotating block 2 is connected with the base 4 through the roller 3, The base 4 is fixed on the lower end frame 6 by fasteners, the inner support ring 5 is placed in the U-shaped groove of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com