Method for improving plastic frame curing rate in LCD (liquid crystal display) panel cell process, and LCD panel

A liquid crystal panel, curing rate technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as liquid crystal leakage, air bubbles, and poor sealability of frame glue 13

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

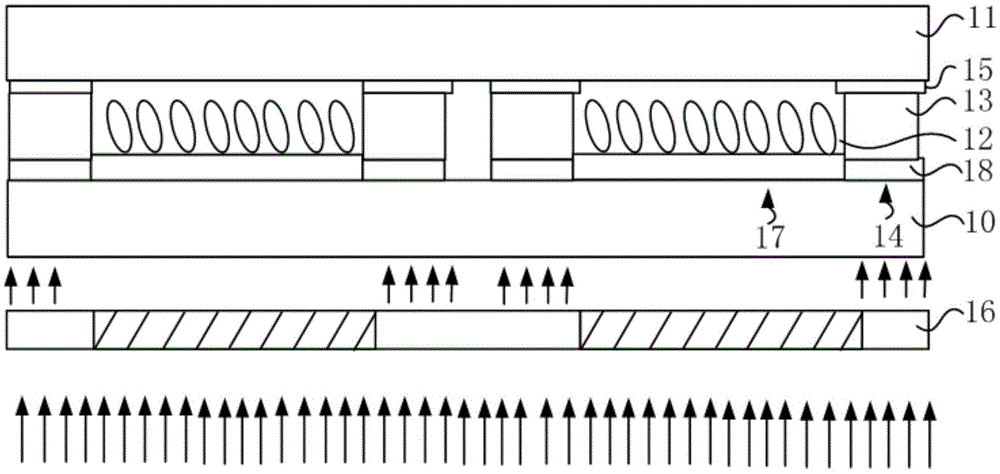

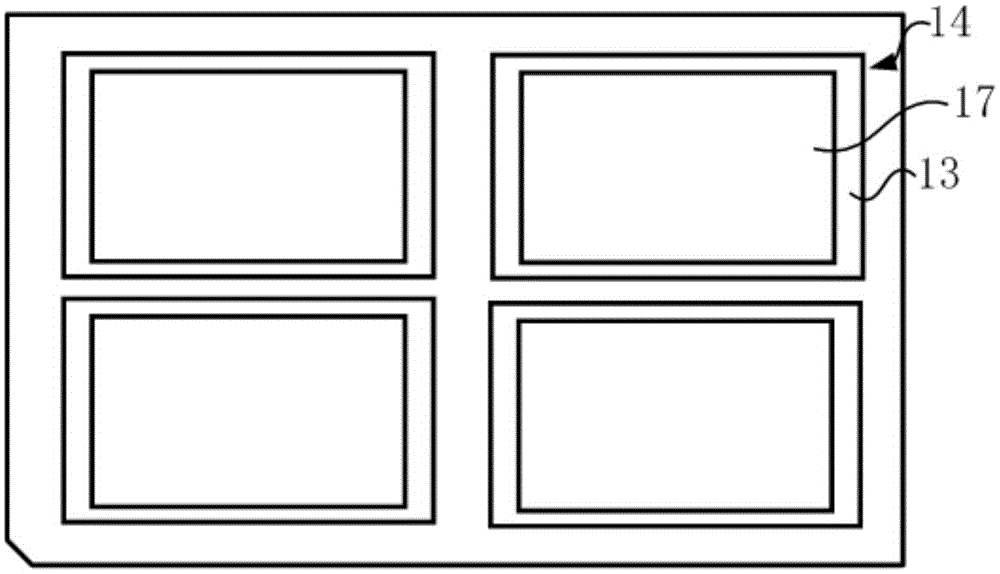

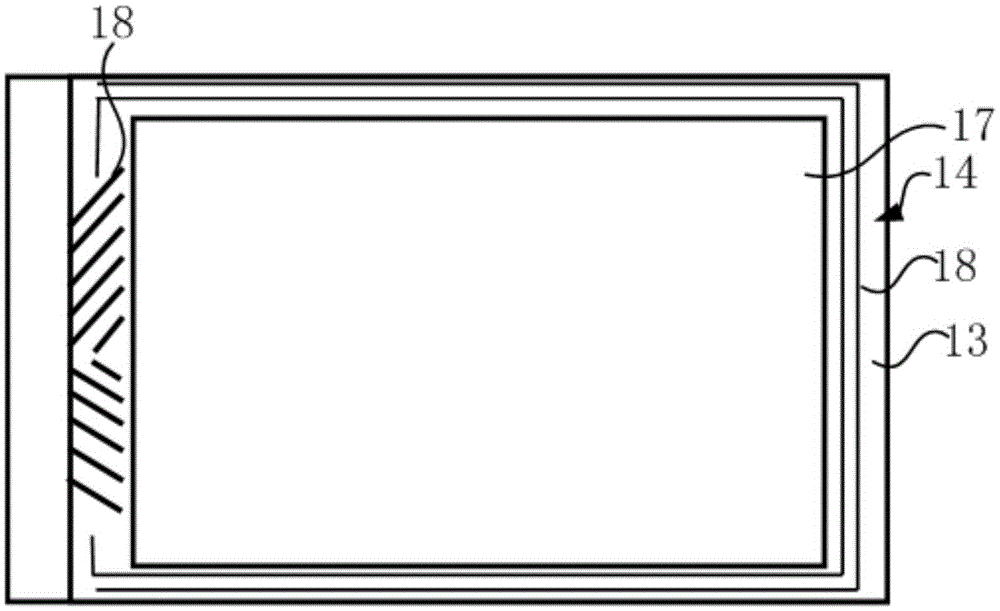

[0023] The method for improving the curing rate of the plastic frame of the liquid crystal panel box forming process provided by the present invention and the specific implementation of the liquid crystal panel will be described in detail below in conjunction with the accompanying drawings.

[0024] see Figure 4 , a method for improving the curing rate of the plastic frame of the liquid crystal panel box forming process, comprising the steps of:

[0025] (a) The assembled array substrate 20 and the color filter substrate 21 are provided.

[0026] Wherein, the non-display area 28 between the array substrate 20 and the color filter substrate 21 is provided with a plastic frame layer 22, and the display between the array substrate 20 and the color filter substrate 21 Region 29 is provided with liquid crystal layer 24 . A light-shielding layer 23 is provided on the non-display area of the surface of the array substrate 20 facing the plastic frame layer 22, and the light-shiel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com