A square liquid aluminum electrolytic capacitor with flexible packaging and its manufacturing process

A technology of electrolytic capacitors and capacitors, which is applied in the direction of liquid electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve the problems of low utilization rate of flat space volume, ineffective use of space, easy accumulation of heat in capacitors, etc., and achieve equivalent series internal resistance And the effect of small impedance, small loss and small pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

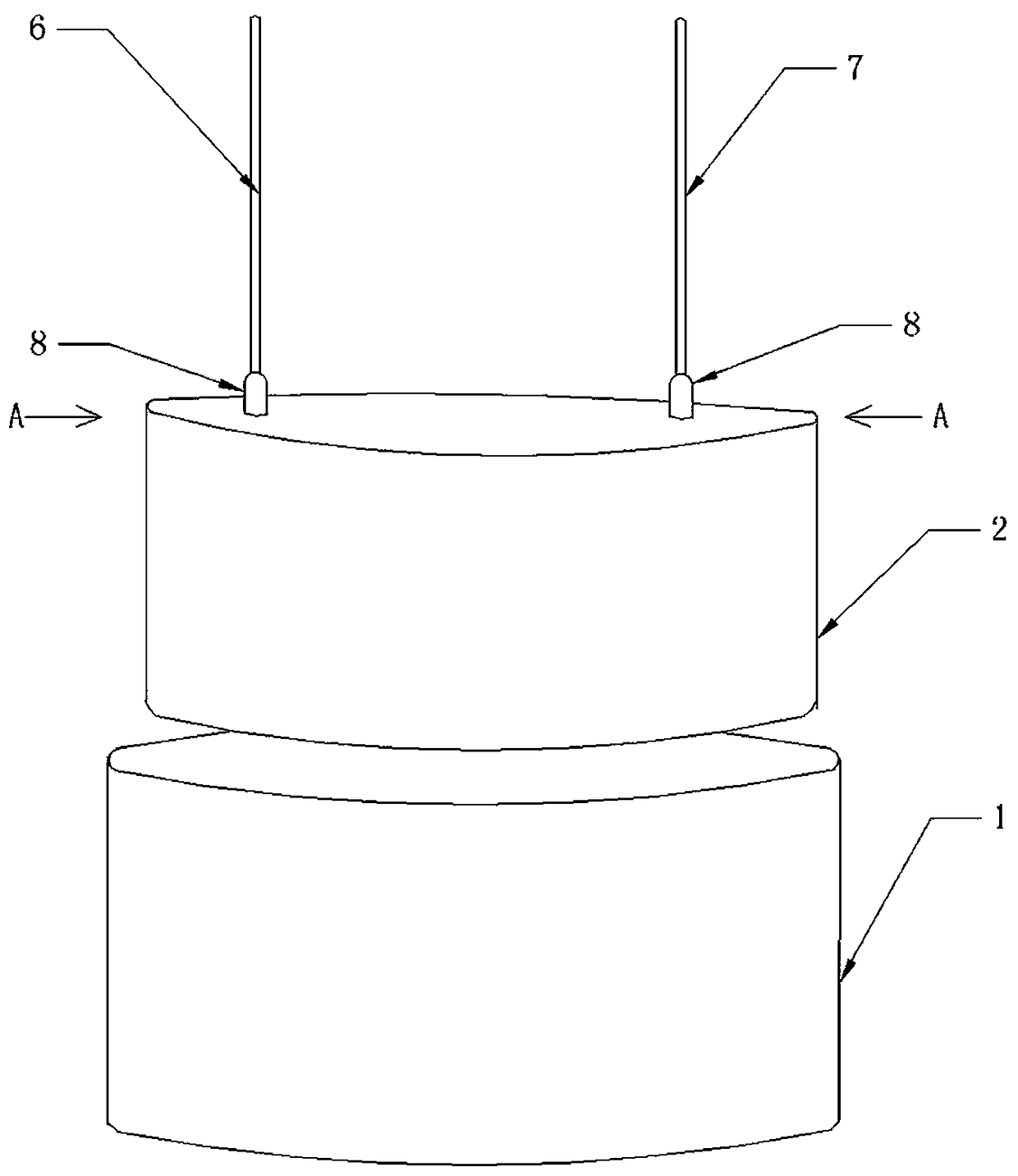

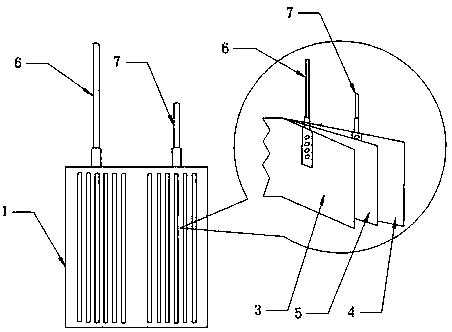

[0027] Such as figure 1 and figure 2 A soft-packaged square liquid aluminum electrolytic capacitor shown includes a soft shell 1 made of aluminum-plastic material and a flat oval capacitor core package 2, and the capacitor core package 2 is sealed in the soft shell 1; Core pack 2 includes anode foil 3, cathode foil 4, electrolytic paper 5, positive electrode lead 6 and negative electrode lead 7, electrolytic paper 5 is located between anode foil 3 and cathode foil 4, positive electrode lead 6 and negative electrode lead 7 are riveted They are respectively connected to the anode foil 3 and the cathode foil 4; the aluminum stem 8 of the positive electrode lead 6 and the negative electrode lead 7 is sealed and connected to the soft shell 1 through PP glue.

[0028] The manufacturing method of the flexible packaged square liquid aluminum electrolytic capacitor of this embodiment includes the following steps: 1) Connecting the positive electrode lead and the negative electrode le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com