Ultrathin square capacitor and manufacturing method thereof

A capacitor and square technology, applied in the field of electronics, can solve the problems of low utilization rate of flat space volume, ineffective use of space, and easy accumulation of heat in capacitors, etc., to achieve the effect of improving utilization rate, less space, and increasing volume capacity density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

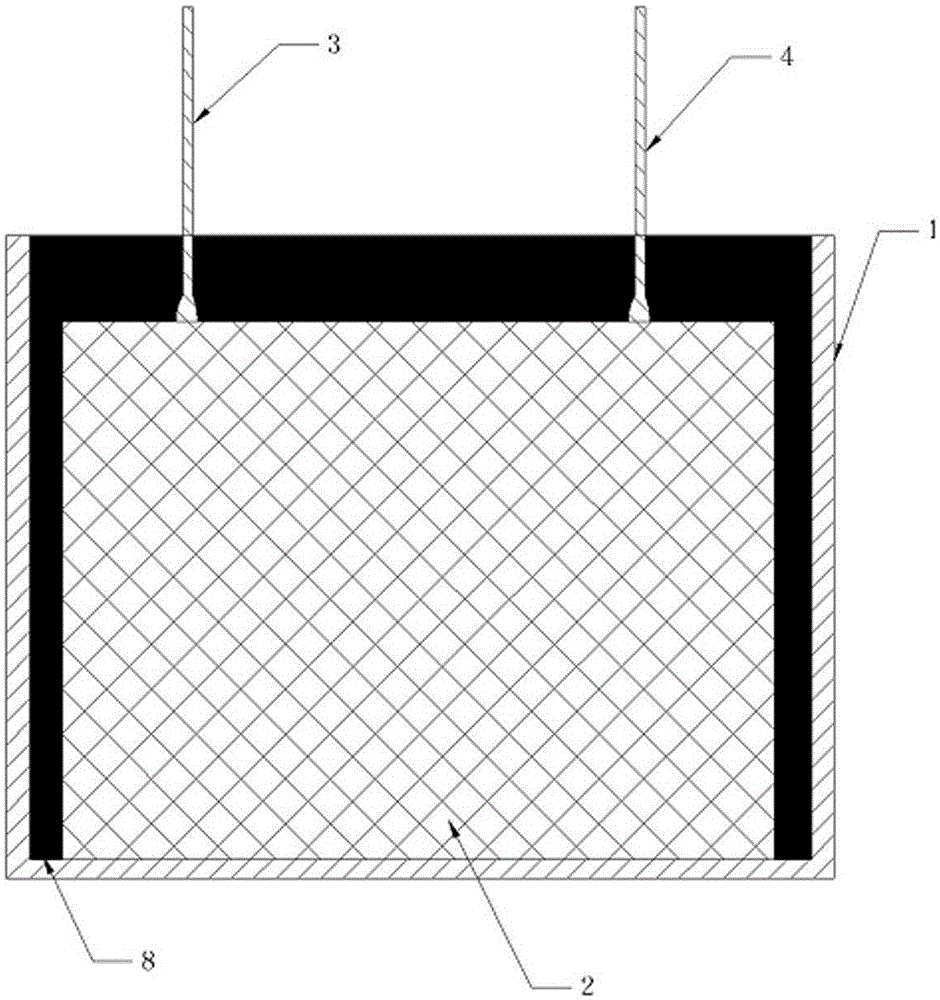

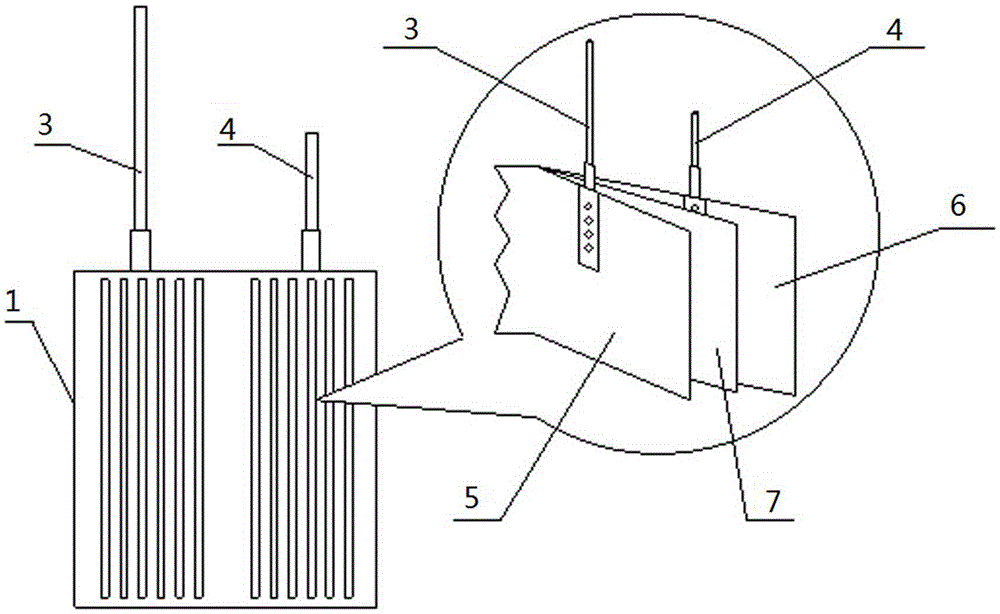

[0021] Such as figure 1 with figure 2 A kind of ultra-thin square capacitor shown, comprises square steel case 1, flat core package 2 and fixed filler 8; Fixed filler 8 seals and fixes flat core package 2 in square steel case 1; Square steel The shell 1 has a thickness of 2-5 mm; the flat core package 2 includes anode foil 5, cathode foil 6, electrolytic paper 7, positive electrode lead 3 and negative electrode lead 4, electrolytic paper 7 is located between the anode foil 5 and cathode foil 6, and the positive electrode The lead wire 3 and the negative electrode lead wire 4 are fixedly connected to the anode foil 5 and the cathode foil 6 respectively and extend out of the square steel shell 1 . Electrolyte paper 7 is impregnated with electrolytic solution, and electrolytic solution includes long linear dibasic carboxylate ammonium salt solutes such as ethylene glycol solvent and ammonium sebacate solvent, and additives such as p-nitrobenzoic acid and ammonium hypophosphite....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com