Multi-stage stator and rotor combined motor

A combined technology of stator and rotor, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of increasing weight and cost, reducing power density, complex structure, etc., and achieve high power density, high work efficiency, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

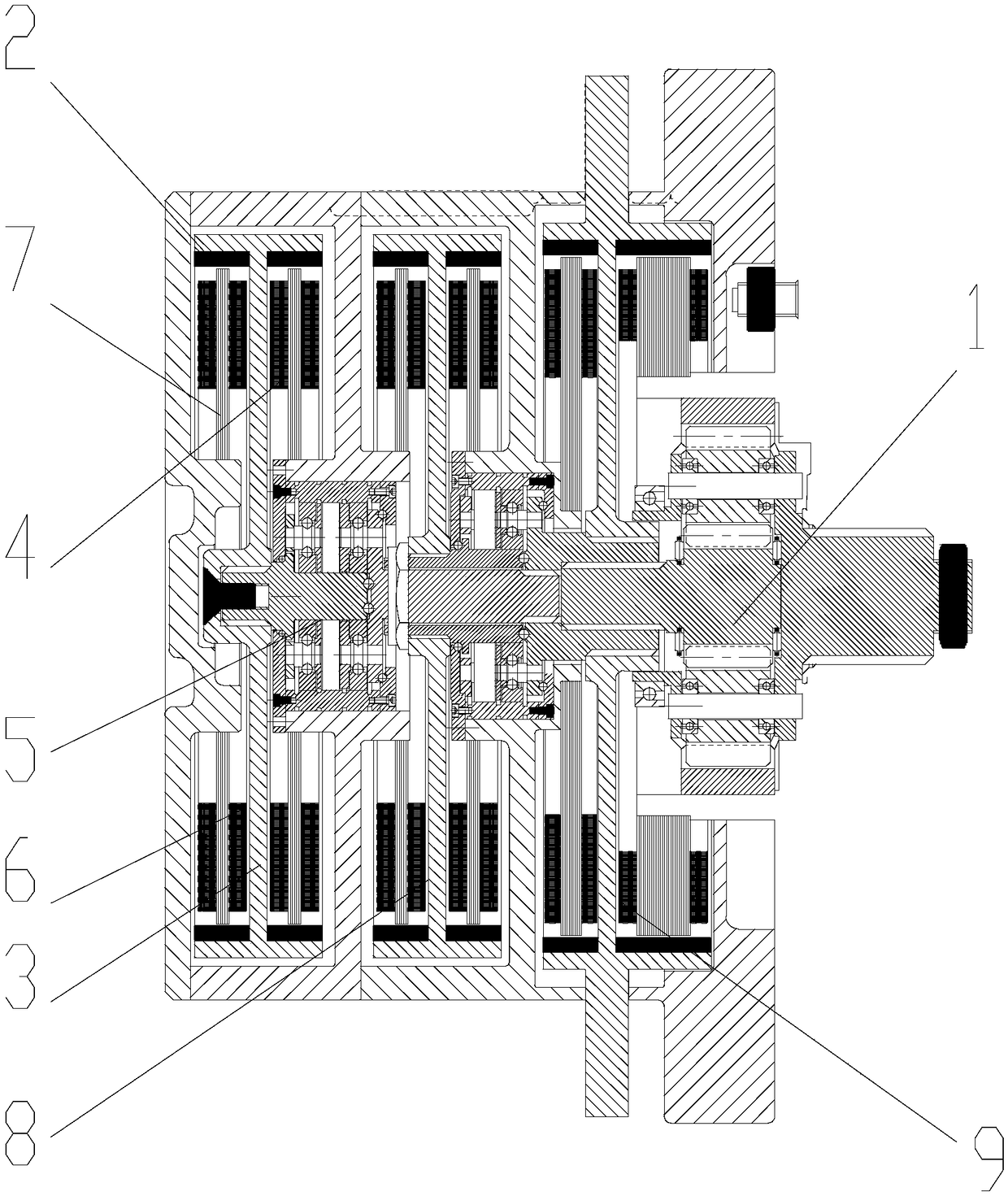

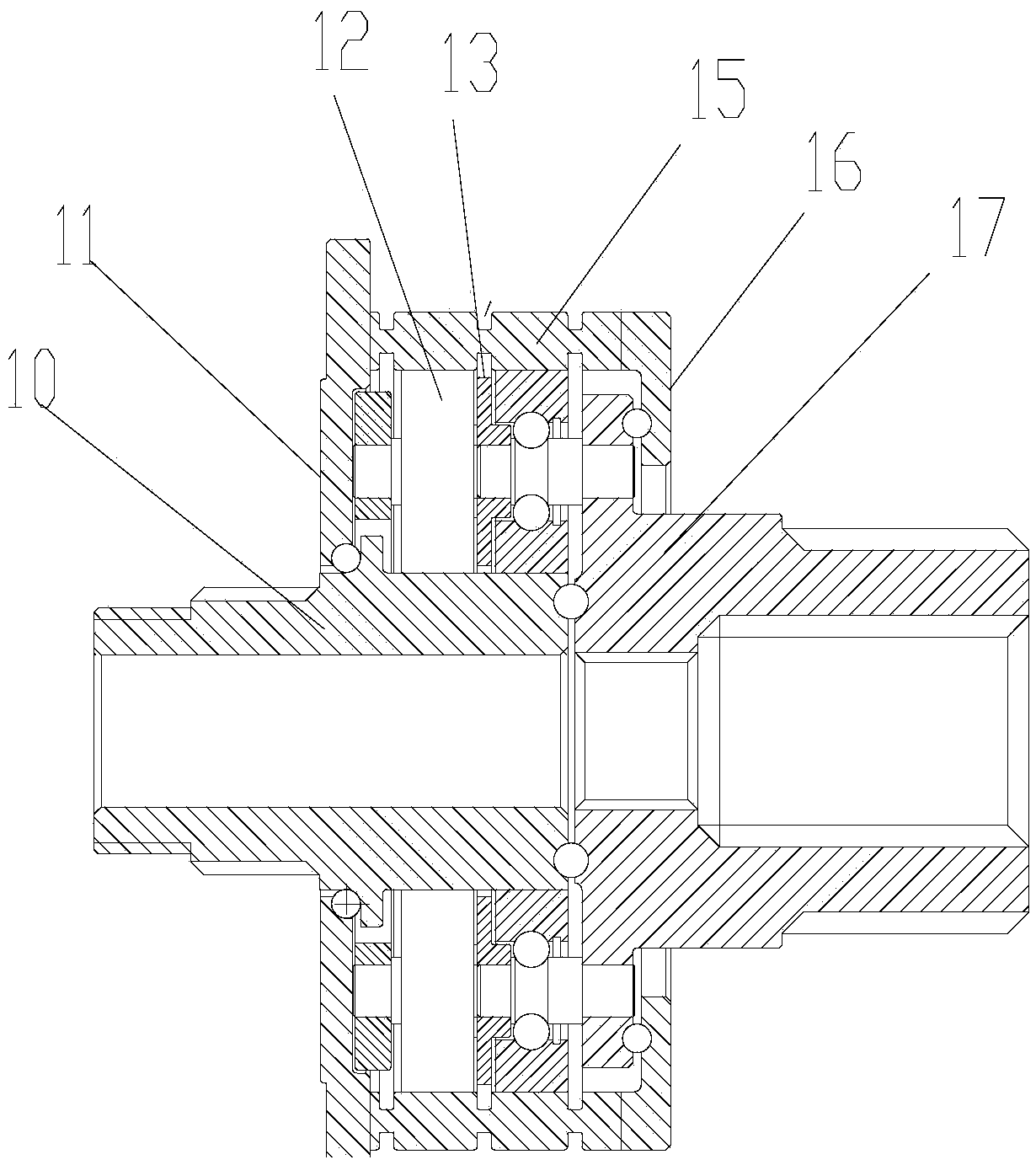

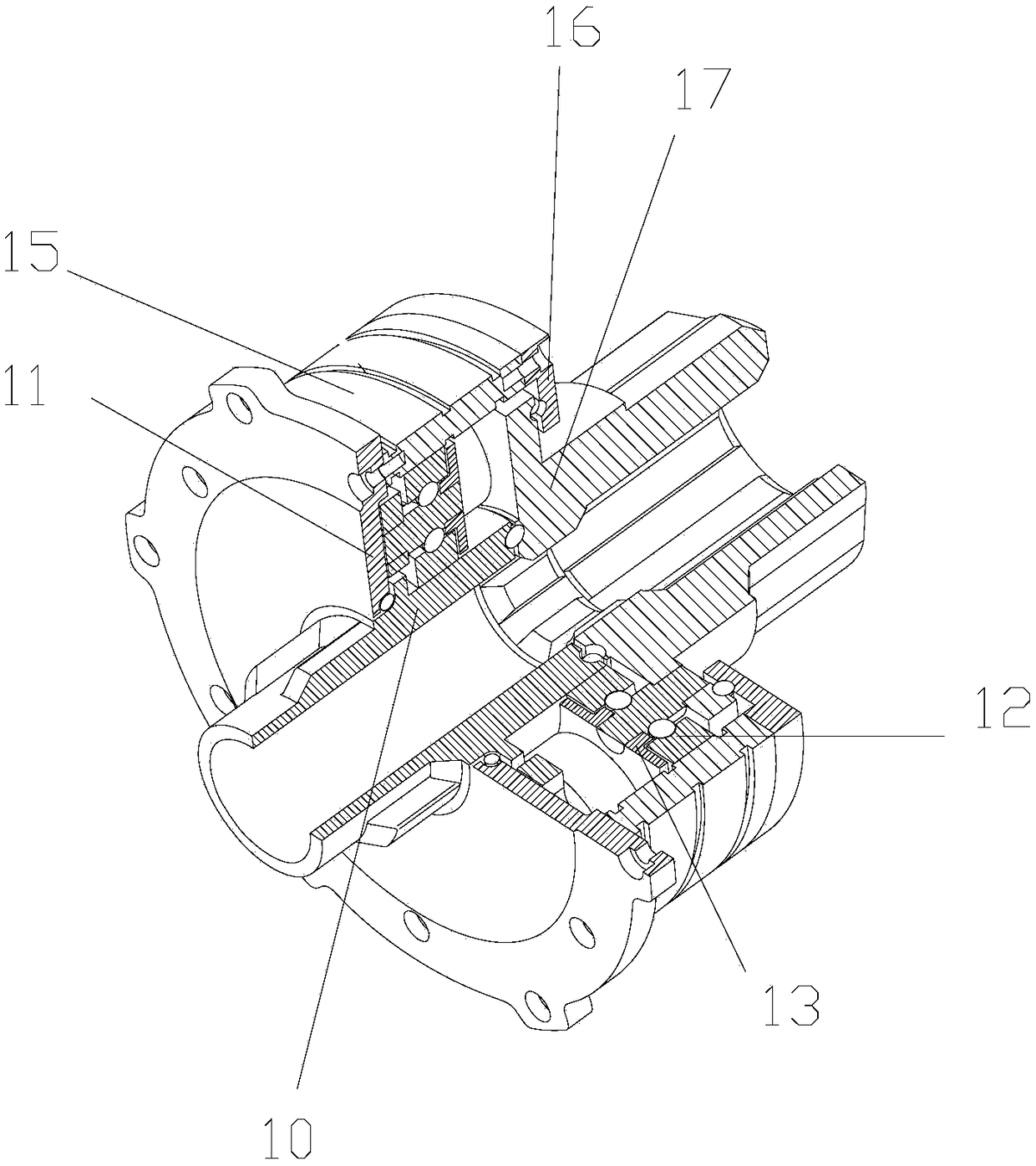

[0023] figure 1 It is a structural schematic diagram of the present invention; as shown in the figure, the multi-stage stator-rotor 3 combined motor of this embodiment includes at least two sub-motors with independent stators 7 and rotors 3, and at least one of the sub-motors is provided with a rotor 3 sub-reducers for power output; the output terminals of each sub-motor are connected and output power, and each stage of stator 7 and rotor 3 can output power and have an independent reduction ratio output. By setting the sub-motors of each level The transmission ratio of the reducer, through their working combination, can achieve wide torque and wide speed range and still maintain high working efficiency. It is suitable for low speed; the middle column motor has a moderate number of pole pairs and is equipped with a sub-reducer with moderate deceleration, and it will be suitable for medium speed; the right column motor has a small number of pole pairs and is equipped with a redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com