A silicone article, a tube and method of forming an article

A silicone and product technology, applied in the direction of catheter, transportation and packaging, thin material processing, etc., can solve problems such as leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

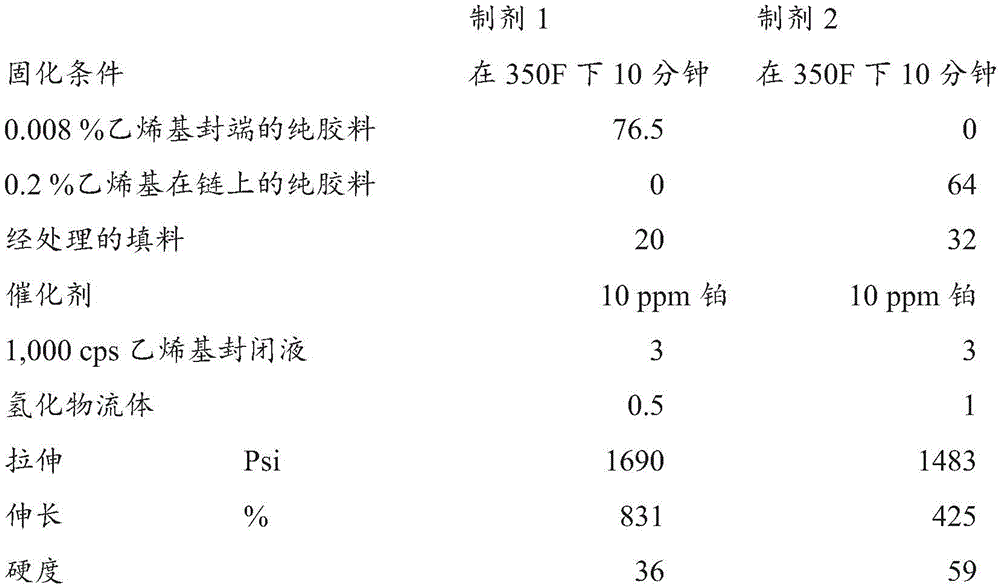

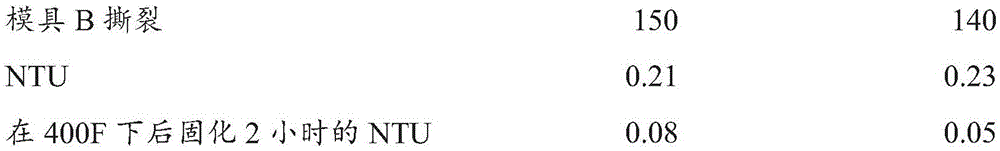

[0064] Using the components seen in Tables 1 and 2 below (amounts expressed in % by weight based on the total weight of the silicone composition), several formulations were mixed and formed into silicone tubes. The silicone matrix component comprises a vinyl-terminated polyalkylsiloxane (ie, indicated as a vinyl-terminated gum having a vinyl content of 0.008% by weight, based on the total weight of the vinyl-terminated gum) , Vinyl-in-chain polyalkylsiloxanes (i.e. indicated as vinyl-in-chain gums having a vinyl content of 0.2% by weight, based on the total weight of the vinyl-in-chain gums ) or a combination thereof. The silicone matrix component has a viscosity greater than 1,000,000 cps. Treated fillers are silica fillers treated with cyclic siloxanes, polydimethylsiloxanes, or combinations thereof. Vinyl terminated silicone polymers are indicated as vinyl blocking fluids with viscosities as indicated. Optional additives include hydride fluids and silicone gums, which ar...

example 2

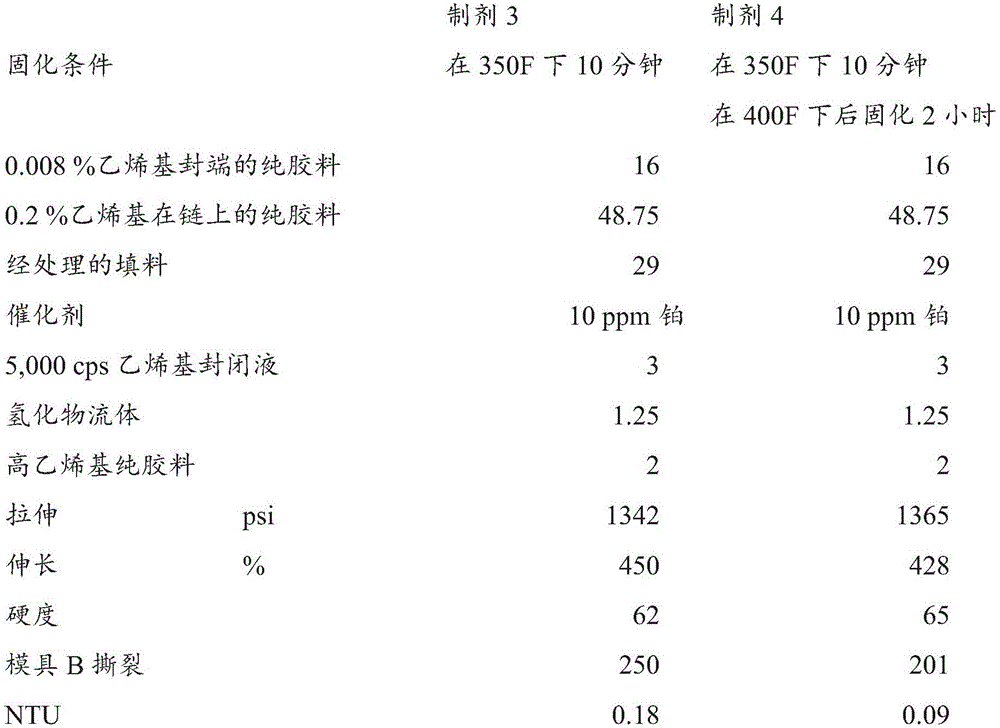

[0072]Commercial samples were tested in comparison to the silicone composition of Example 1. The matrix is cured with 1 part hydride and 10 ppm platinum and is an industrial and medical grade silicone composition for tubing and moldings. Grades and suppliers are listed below along with turbidity results. Samples indicated as "post-cured" were exposed to heating at 400°F for 2 hours.

[0073] table 3

[0074]

[0075] Clearly, Formulations 1, 2, 3 and 4 of Example 1 had lower turbidity values compared to the commercially available formulations. In particular, Formulations 1, 2, 3, and 4 of Example 1 had turbidity values of less than about 0.3 NTU, while the commercially available formulations had turbidity values of greater than 0.38 NTU. The samples from Dow Corning had the lowest turbidity values at 0.56 NTU and 0.59 NTU, respectively. However, even post curing of the samples from Dow Corning did not provide the same haze values as the current formulations....

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com