Urea solution jet control method of denitrification system based on dual MAPs

A MAP map, solution injection technology, applied in the controller, separation method, electric controller with specific characteristics, etc., can solve the problems of ammonia leakage, non-compliance with emission standards, low nitrogen oxide conversion rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

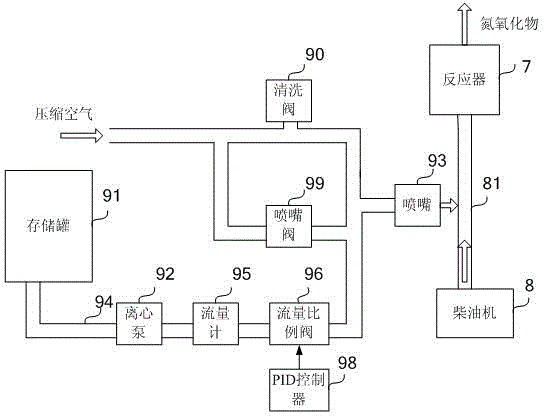

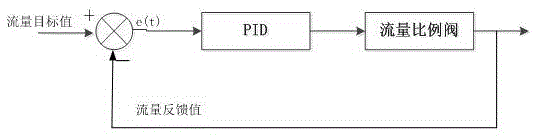

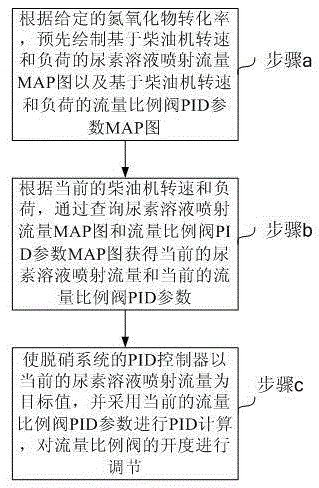

[0017] see image 3 . According to an embodiment of the present invention, a method for controlling urea solution injection in a denitrification system based on a double MAP diagram, wherein the denitrification system includes a flow proportional valve for controlling the injection flow rate of the urea solution, and the opening of the flow proportional valve is Controlled by a PID controller. The urea solution injection control method for the denitrification system based on the double MAP diagram comprises the following steps:

[0018] Step a, according to the given nitrogen oxide conversion rate, draw in advance the urea solution injection flow MAP diagram based on the diesel engine speed and load and the flow proportional valve PID parameter MAP diagram based on the diesel engine speed and load;

[0019] Step b, according to the current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com