A biochar adsorbent for highly efficient adsorption of rare earth lanthanum

A biochar and adsorbent technology, applied in the direction of adsorption of water/sewage treatment, water pollutants, and other chemical processes, can solve the problems of high price, inability to prepare on a large scale, poor adsorption effect, etc., and achieve low production costs and raw materials Natural and efficient adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A biochar adsorbent for highly efficient adsorption of rare earth lanthanum, the biochar adsorbent is made of the following raw material components mixed and then carbonized according to mass percentage: 75% hijiki, 10% sea wormwood, and 15% sargassum . The specific method of carbonization is as follows: after mixing the raw material components, cracking at 700° C. for 3 hours in an oxygen-free environment, and cooling naturally.

[0023] The biochar adsorbent becomes a finished product after being treated with a dilute alkali solution. The specific treatment of the dilute alkali solution is: place the biochar adsorbent in a sodium hydroxide solution with a concentration of 0.3mol / L, heat it to 45°C, soak it for 5 hours, and take it out. Finally, rinse with distilled water, dry at 80°C for 24 hours, crush and pass through a 60-mesh sieve.

Embodiment 2

[0025] A biochar adsorbent for efficiently adsorbing rare earth lanthanum, the biochar adsorbent is made of the following raw material components mixed and then carbonized according to mass percentage: 90% hijiki, 5% sea wormwood, and 5% sargassum . The specific method of carbonization is as follows: after mixing the raw material components, cracking at 700° C. for 3 hours in an oxygen-free environment, and cooling naturally.

[0026] The biochar adsorbent becomes a finished product after being treated with a dilute alkali solution. The specific treatment of the dilute alkali solution is: place the biochar adsorbent in a sodium hydroxide solution with a concentration of 0.5mol / L, heat it to 35°C, soak it for 8 hours, and take it out Finally, rinse with distilled water, dry at 80°C for 24 hours, crush and pass through a 60-mesh sieve.

Embodiment 3

[0028] A biochar adsorbent for highly efficient adsorption of rare earth lanthanum, the biochar adsorbent is made of the following raw material components mixed and carbonized according to mass percentage: 80% hijiki, 8% sea wormwood, and 12% sargassum . The specific method of carbonization is as follows: after mixing the raw material components, cracking at 700° C. for 3 hours in an oxygen-free environment, and cooling naturally.

[0029] The biochar adsorbent becomes a finished product after being treated with a dilute alkali solution. The specific treatment of the dilute alkali solution is: place the biochar adsorbent in a sodium hydroxide solution with a concentration of 0.4mol / L, heat it to 40°C, soak it for 6 hours, and take it out. Finally, rinse with distilled water, dry at 80°C for 24 hours, crush and pass through a 60-mesh sieve.

[0030] Product performance test research:

[0031] 1. Method

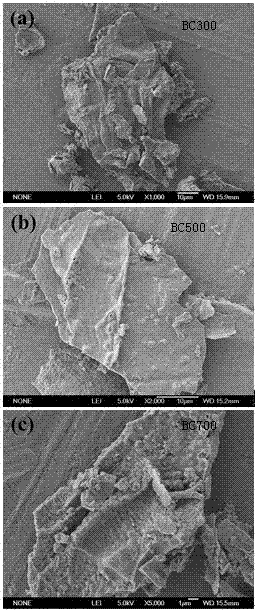

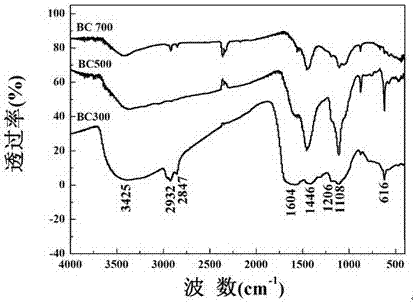

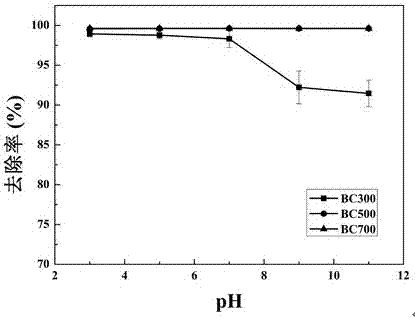

[0032] 1.1 Preparation of biochar adsorbents at different pyrolysis tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com