Plate hammer for overlaying of impact crusher

A technology of impact crusher and blow bar, which is applied in the direction of grain processing, etc., and can solve the problems of easy drop of wear-resistant layer, short service life, low material utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

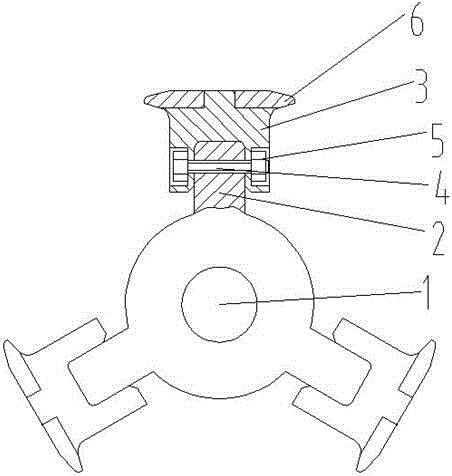

[0013] The present invention relates to a blow bar for overlay welding of an impact crusher, such as figure 1 As shown, it includes a rotor body 1 , an elongated convex body 2 and a blow bar 3 .

[0014] The strip-shaped protrusions 2 are provided with a plurality of them and are evenly distributed on the outer surface of the rotor body 1, and the blow bars 3 are provided with grooves, and the strip-shaped protrusions 2 and the blow bars 3 corresponding to the setting of the groove.

[0015] The elongated convex body 2 is provided with a through bolt hole, the blow bar 3 is provided with a trapezoidal hole corresponding to the bolt hole, and the bolt 4 passes through the trapezoidal hole and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com