A mechanical arm device for changing the liner of a ball mill

A technology of robotic arms and ball mills, applied in manipulators, grain processing, manufacturing tools, etc., can solve the problems of unsafe working environment, expensive equipment, safety accidents, etc., so as to improve the working environment of workers, reduce manufacturing costs, and reduce operations. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

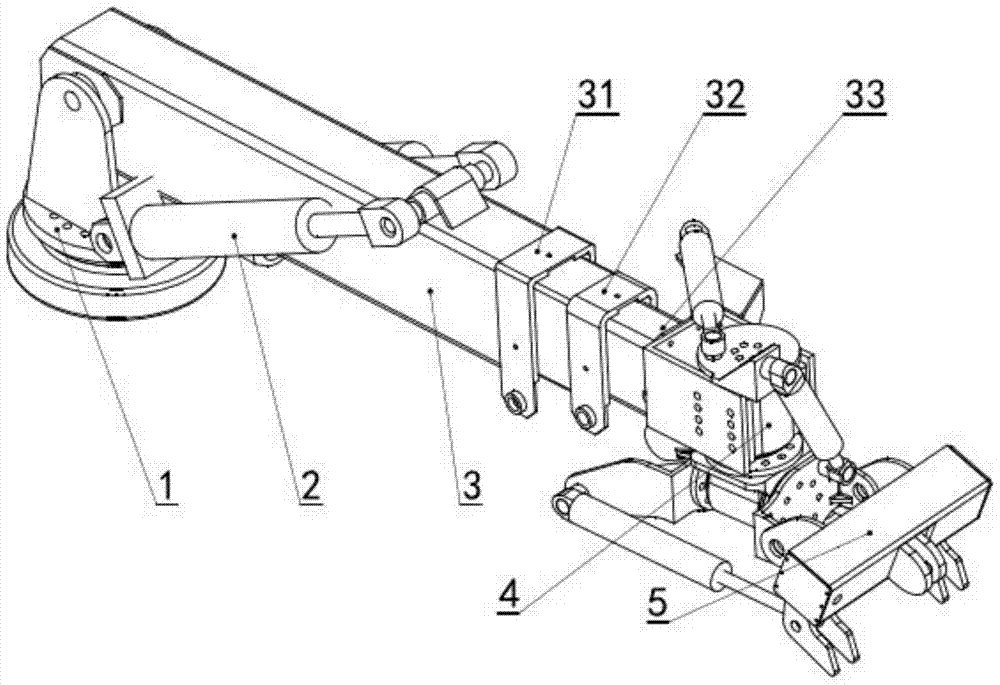

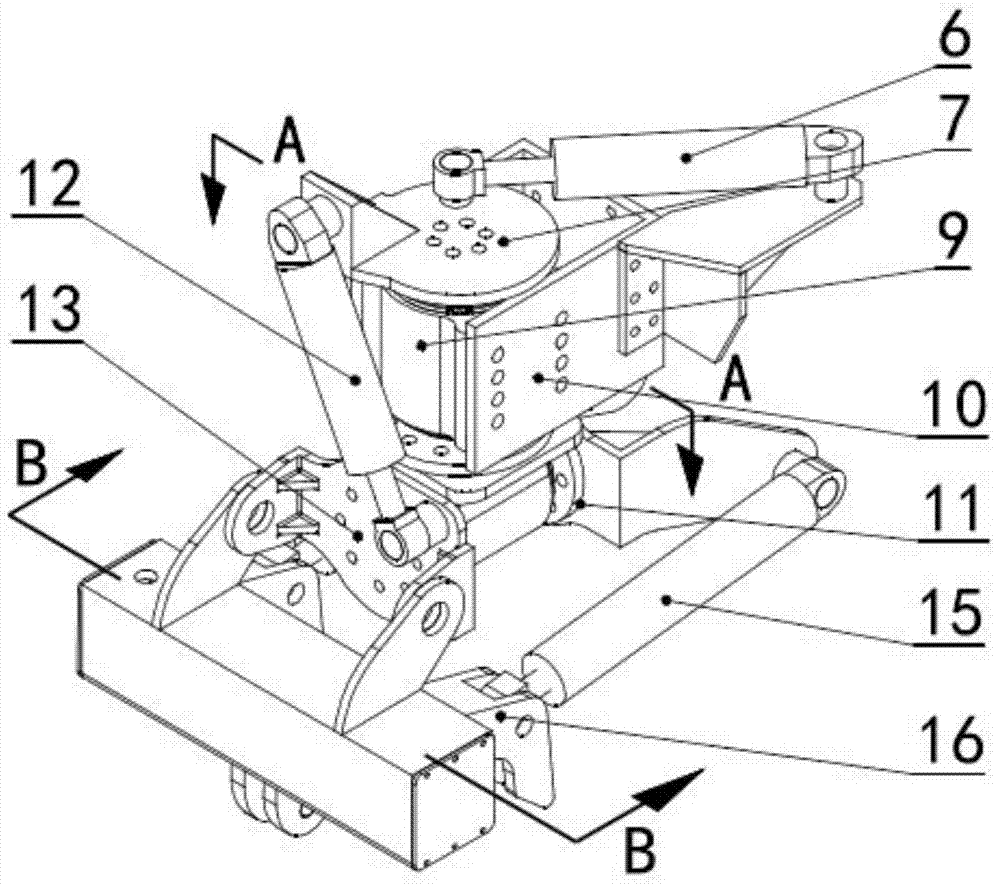

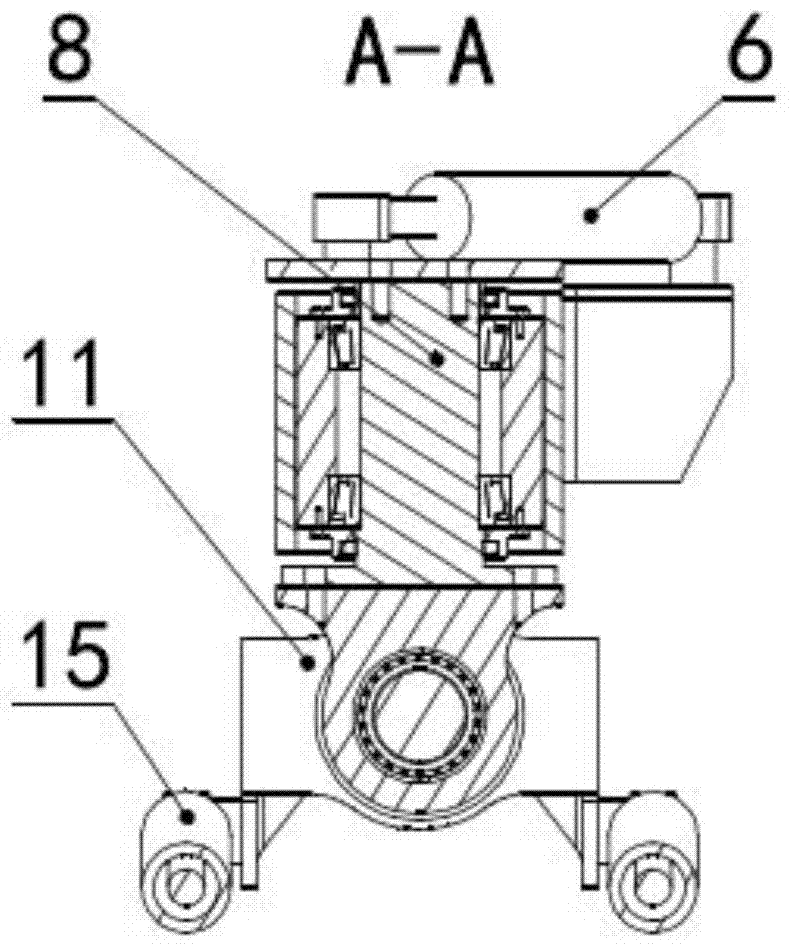

[0033] A ball mill relining mechanical arm device, such as figure 1 As shown, it includes a slewing support mechanism 1, a boom lifting mechanism 2, a boom telescopic mechanism 3, a wrist mechanism 4 and a clamping device 5; the slewing support mechanism 1 is connected with the boom telescopic mechanism 3, and the boom Both ends of the arm lifting mechanism 2 are respectively connected with the slewing support mechanism 1 and the telescopic boom mechanism 3 ; the telescopic boom mechanism 3 is connected with the wrist mechanism 4 ; and the wrist mechanism 4 is connected with the clamping device 5 .

[0034] The slewing support mechanism 1 is the support point of the entire mechanical arm, driven by a servo motor, and can rotate around the slewing support axis, and the structure of the slewing support mechanism 1 is an existing mature technology;

[0035] The boom lifting mechanism 2 is driven by a hydraulic cylinder and can rotate around the slewing support axis of the slewing...

Embodiment 2

[0044] A ball mill relining mechanical arm device, such as figure 1 As shown, it includes a slewing support mechanism 1, a boom lifting mechanism 2, a boom telescopic mechanism 3, a wrist mechanism 4 and a clamping device 5; the slewing support mechanism 1 is connected with the boom telescopic mechanism 3, and the boom Both ends of the arm lifting mechanism 2 are respectively connected with the slewing support mechanism 1 and the telescopic boom mechanism 3 ; the telescopic boom mechanism 3 is connected with the wrist mechanism 4 ; and the wrist mechanism 4 is connected with the clamping device 5 .

[0045] The slewing support mechanism 1 is the support point of the entire mechanical arm, driven by a servo motor, and can rotate around the slewing support axis, and the structure of the slewing support mechanism 1 is an existing mature technology;

[0046] The boom lifting mechanism 2 is driven by a hydraulic cylinder and can rotate around the slewing support axis of the slewing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com