Turnover tool of low-speed and large-torque motor stator and application method of turnover tool

A motor stator, high torque technology, applied in the manufacture of stator/rotor body, etc., can solve the problems of affecting the quality of the motor, the mass of the stator core, and difficult operation, and achieve the effect of avoiding wire package damage and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

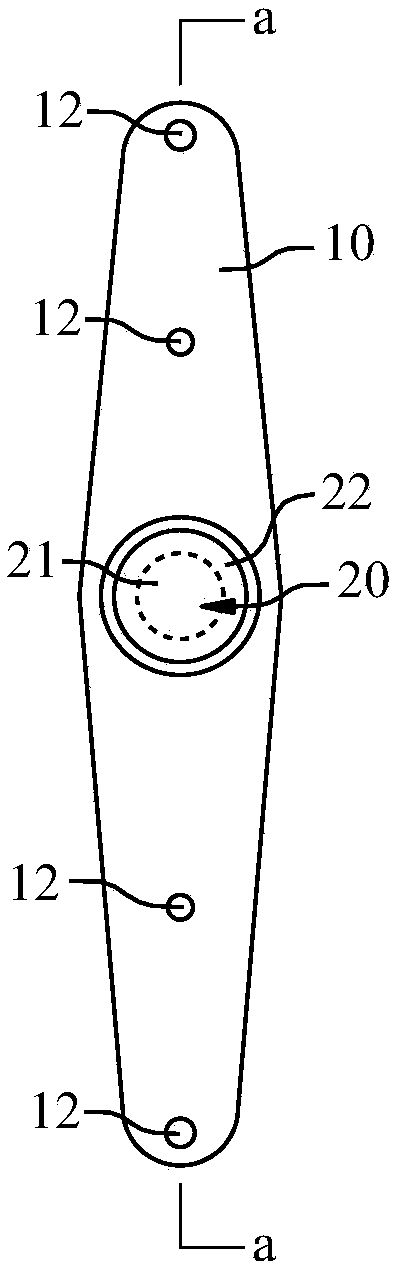

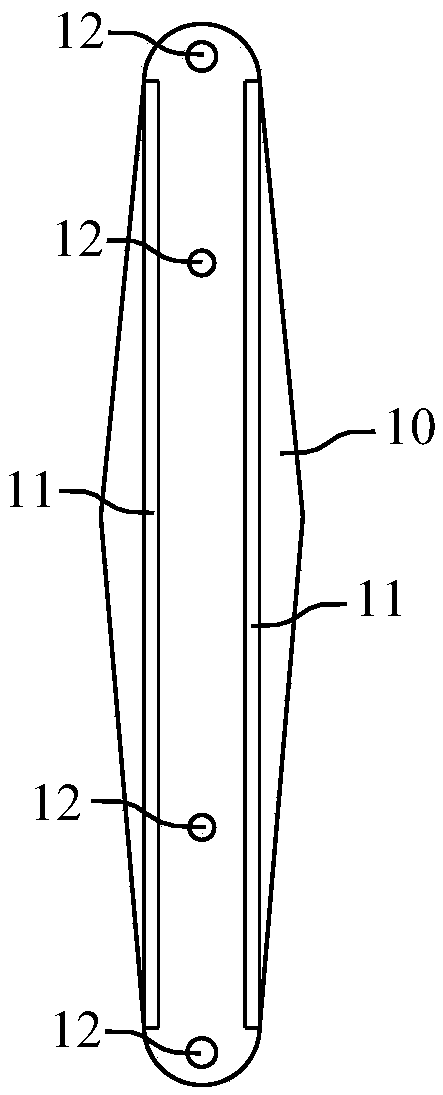

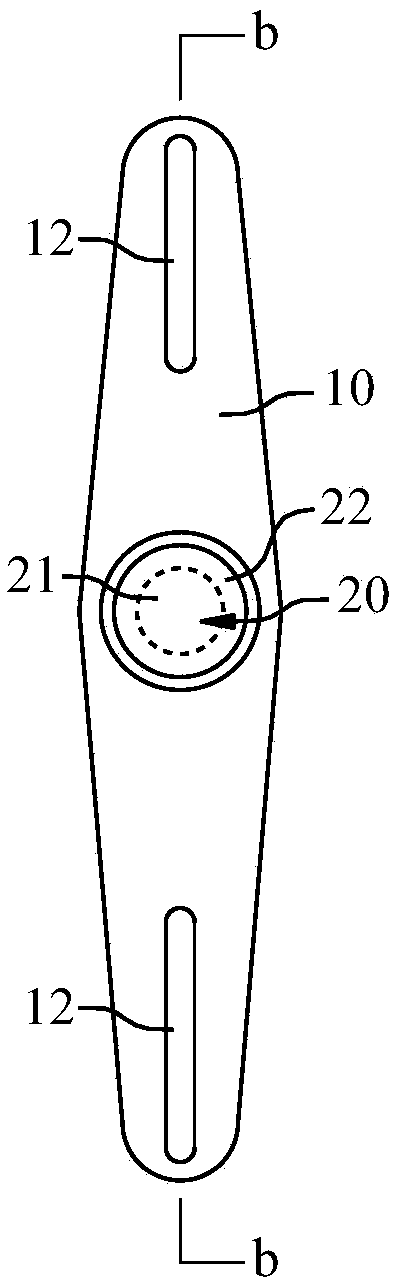

[0022] Attached below Figure 1-10 , through the description of the embodiments, the specific implementation of the present invention will be further described in detail.

[0023] A low-speed, high-torque motor stator turning tool includes a base plate 10, which forms a detachable mating connection with a stator core A, and a lifting ear 20 is provided on the outer surface of the base plate 10. When in use, it is necessary to symmetrically install the base plates 10 of the two turning tools on both sides of the stator core A respectively, and then hang the flexible belt-shaped sling of the hoisting device on the lifting lug 20, because the two lifting lugs 20 The axes coincide, so that after the hoisting device is started and the stator is hoisted to a suitable position, the stator will turn over with the axis of the two lifting lugs 20 as the axis of rotation, thereby realizing the adjustment of the attitude. The turning tool has a simple structure, and when used in conjunct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com