Automatic extracting device for core movable blocks of integrated turbine casing exhaust air chamber

A technology of automatic extraction and turbine shell, applied in casting and forming equipment, metal processing equipment, molding machines, etc., to achieve the effect of improving the matching accuracy, reducing the matching surface and reducing the maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

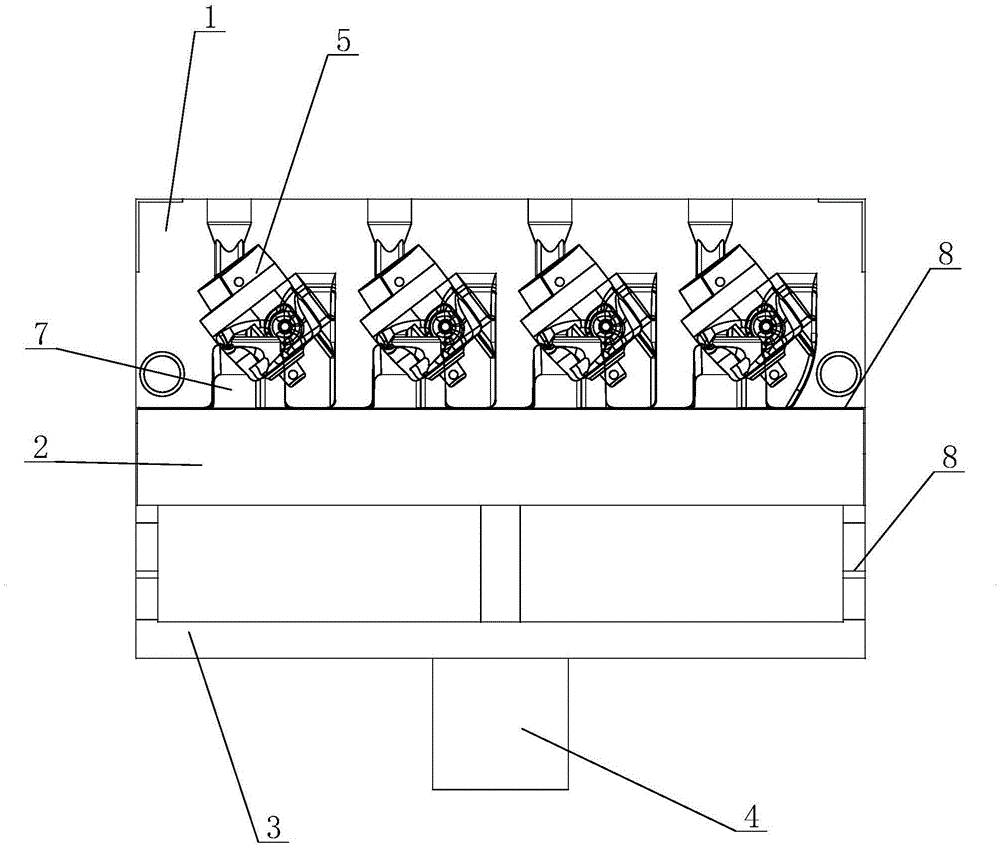

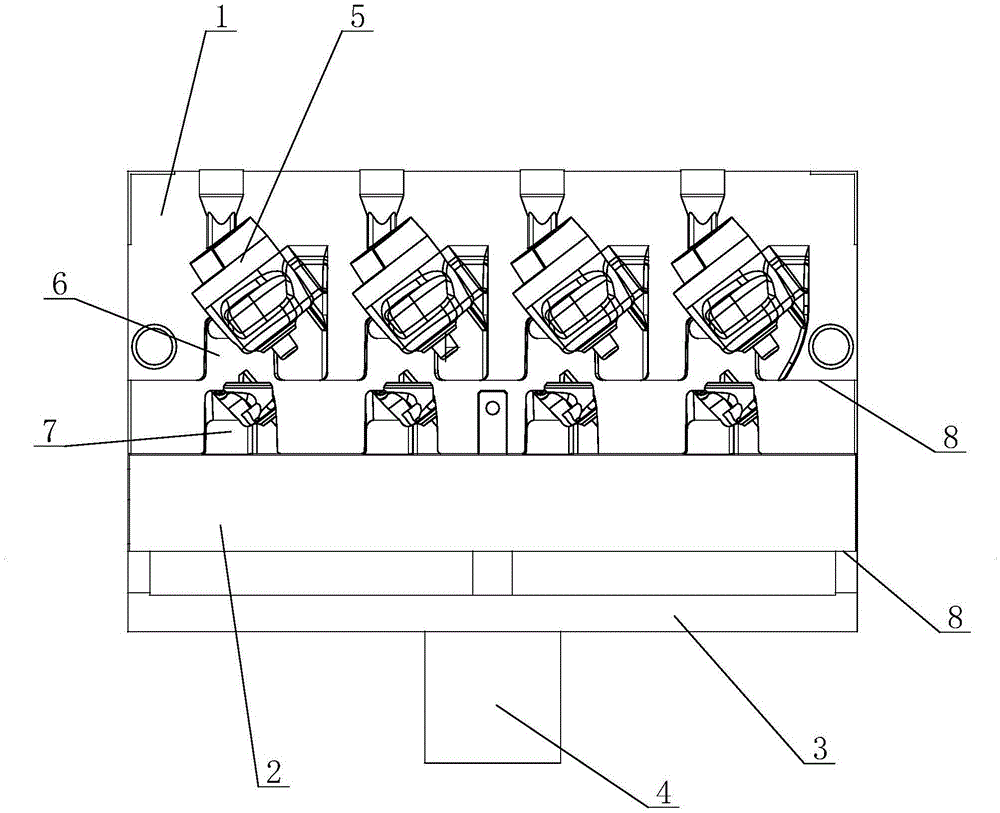

[0015] see figure 1 and figure 2 As shown, in this embodiment, an integrated automatic extraction device for the core of the exhaust gas chamber of the turbine casing includes a core box body 1, a base 2, a mounting seat 3 and a driving cylinder 4, and several A sand core forming part 5, and the core box body 1 is provided with a loose block accommodating cavity 6 with a bottom opening under each of the sand core forming parts 5, and the size of the loose block accommodating cavity 6 is The movable block 7 is arranged in accordance with the shape, and a movable block 7 is provided corresponding to each movable block accommodating cavity 6, and all the movable blocks 7 are arranged on a base 2 at intervals, and the mounting seat 3 is arranged on the core box body 1 The bottom, on which a drive cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com