Assembly line assembly method for clutch armature of die-casting machine

An assembly method and clutch technology, which are applied in the field of die-casting machine assembly production lines, can solve the problems of labor intensity, poor safety, poor fixation of inclined iron base and coupling body, etc., and achieve the goals of reducing labor intensity, improving assembly efficiency, and facilitating screw assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

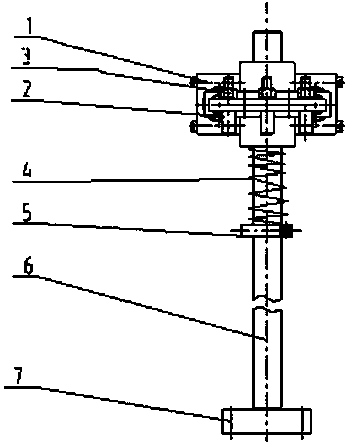

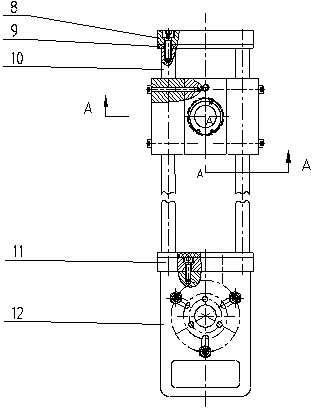

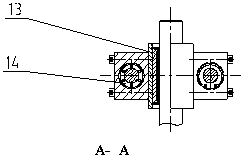

[0032] Specific implementation method: a method for assembling the clutch armature assembly line of a die-casting machine. In this method, at the assembly station of the clutch armature on the assembly line of the die-casting machine, workers use electric tightening guns to realize the assembly, tightening and fixing of the center screw in the middle of the clutch armature; Its feature is that before the assembly, tightening and fixing of the central screw, the auxiliary tooling is used to clamp and fix the coupling body in the middle of the clutch armature, so as to ensure the smooth tightening of the central screw and ensure the safety of personal operation.

[0033] Specifically, in this embodiment, the auxiliary tooling such as Figure 1-3 As shown, it includes a coupling body clamping part for clamping and fixing the three sides of the coupling body triangle. The coupling body clamping part is connected with a transverse connecting rod 10 extending horizontally outward, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com