Rotating device used in vertical lathe

A technology of rotating device and vertical lathe, applied in auxiliary devices, turning equipment, accessories of toolholders, etc., can solve the problems of short service life of parts, difficult automatic control, low transmission efficiency, etc., and achieve extended service life and convenient operation. , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

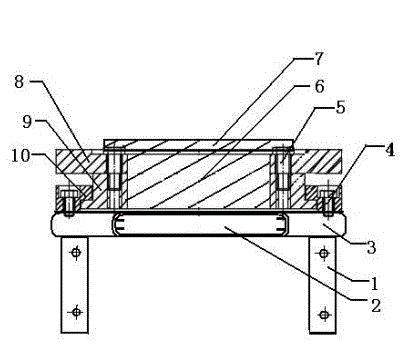

[0012] This embodiment provides a rotating device used in a vertical lathe, characterized in that: the rotating device used in a vertical lathe includes a support column (1), a turntable (2), and a mounting seat (3) , the first bolt (4), the second bolt (5), the weighing core plate (6), the workbench (7), the second transmission part (8), the first transmission part (9), the clamping block (10 );

[0013] Among them: the support column (1) is provided with the mounting seat (3) for installing the turntable, the turntable (2) is provided with a weighing core disc (6), and the weighing core disc (6) is equipped with a workbench (7). The upper part fixes the second transmission part (8) through the second bolt (5), and the first transmission part (9) is arranged under the second transmission part (8), and the first bolt (4) and the clamping block (10) will The first transmission member (9) is fixed and clamped.

[0014] The mounting seat (3) is in the shape of a ring, the turnt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com