Portable inclined hole drilling device

A portable, oblique hole technology, which is applied in the field of drilling devices and portable oblique hole drilling devices, can solve the problems of long cycle, high cost, difficulty in manufacturing, storage and management, etc., and achieve low production cost, simple operation and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

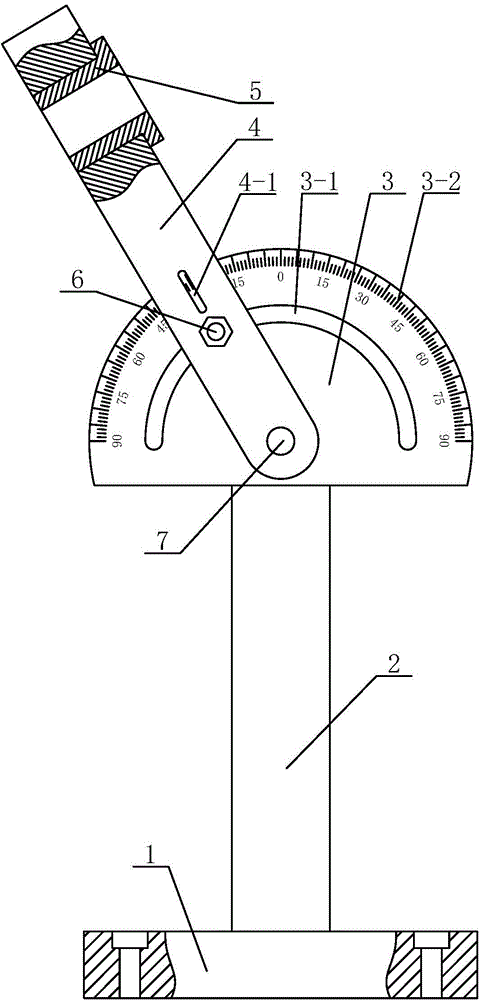

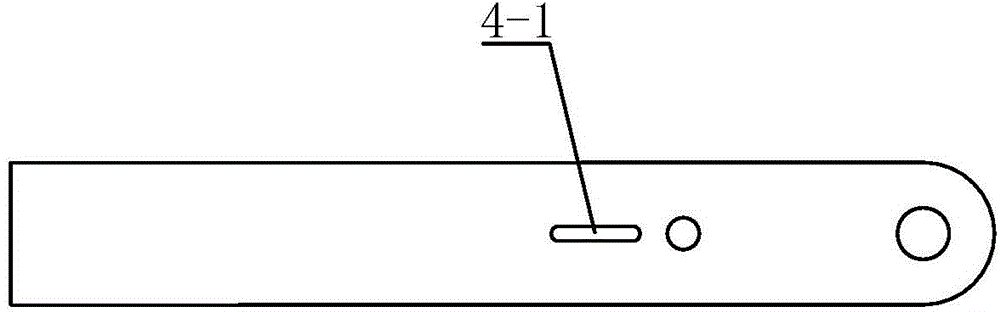

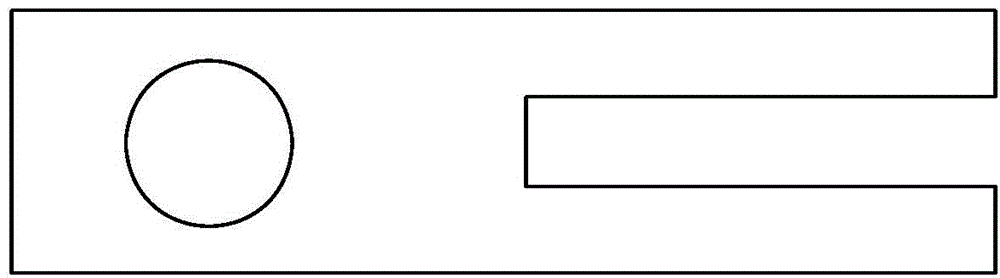

[0021] like Figure 1-Figure 3 The shown portable inclined hole drilling device includes a base 1 for fixed support and a drill sleeve 5 for guiding the drill bit to drill holes, and also includes a fan-shaped guide plate 3 with a scale 3-2 and for installing The drilling template 4 of the drill sleeve 5; the base 1 is fixedly connected to the lower end of the support arm 2, and the upper end of the support arm 2 is fixedly equipped with the fan-shaped guide plate 3, and the center position of the fan-shaped guide plate 3 is connected to the drill One end of the template 4 is rotatably connected, the other end of the drill template 4 is equipped with the drill sleeve 5, and the central axis position of the drill template 4 is provided with an observation hole 4-1 for observing the scale 3-2, and the observation hole 4 -1 can be used in conjunction with the scale table 3-2 to conveniently observe the angle of inclination of the drilling template 4. The middle part of the fan-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com