Self-centering clamp used for taper hole product

A self-centering fixture and product technology, applied in the field of machining tooling, can solve the problems of reduced processing efficiency, crushed taper holes, affecting processing accuracy, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

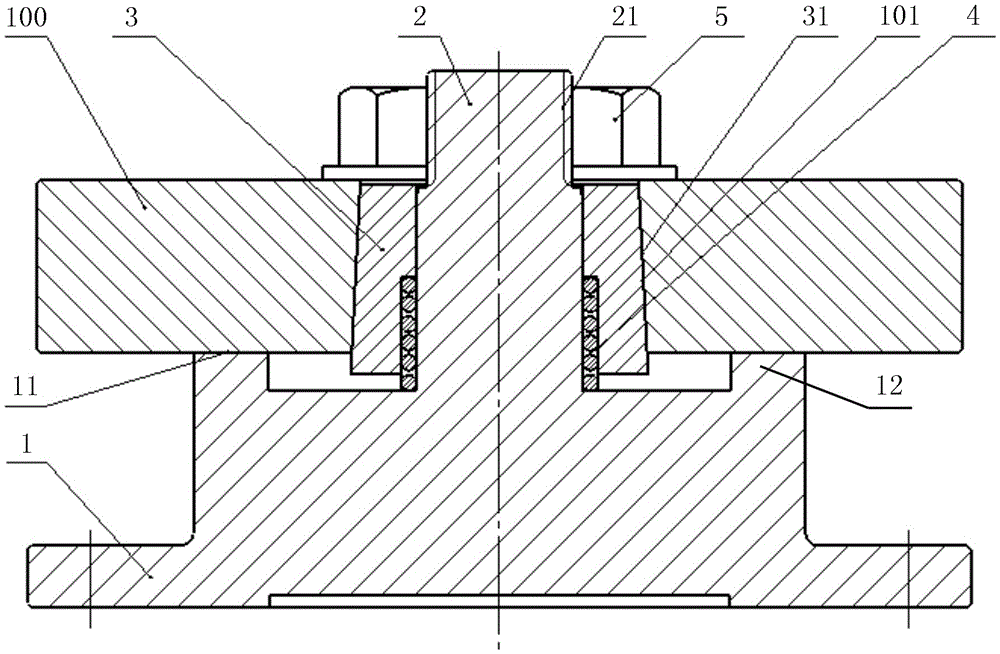

[0014] like figure 1 As shown, the self-centering fixture for tapered hole products of the present invention includes a base 1, on which a mandrel 2 is fixed, and a sliding sleeve on the mandrel 2 is provided with a tapered hole 101 for inserting a product 100 to be processed The taper sleeve 3 for radial positioning is formed in the middle, the taper of the taper surface 31 of the taper sleeve 3 is consistent with the taper of the taper hole 101, the base 1 is provided with an axial positioning surface 11 for contacting with the product 100 to be processed, and the self-centering fixture also It includes a detachable locking assembly for pressing and fixing the product 100 to be processed on the axial positioning surface 11 to prevent the product 100 to be processed from moving in the axial direction of the mandrel 2, and the base 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com