Mechanical hand device

A technology of manipulators and manipulators, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of broken ropes, swing angles, and inability to accurately grasp objects, etc., and achieve the effect of enhancing the force value of the ropes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

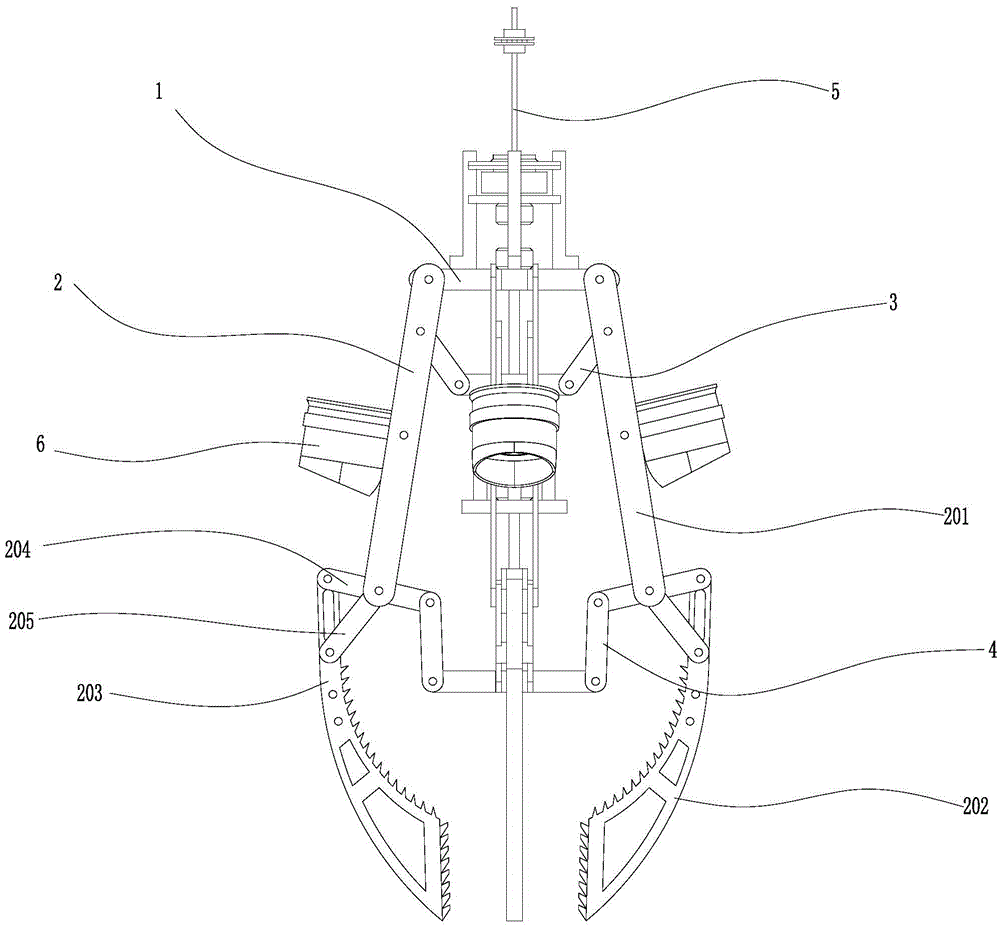

[0044] Such as figure 1 As shown, the manipulator device of this embodiment includes: a frame 1 , at least one pair (for example, two pairs) of grasping mechanisms 2 that open and close synchronously, a first control mechanism 3 , a second control mechanism 4 , and a suspension mechanism 5 .

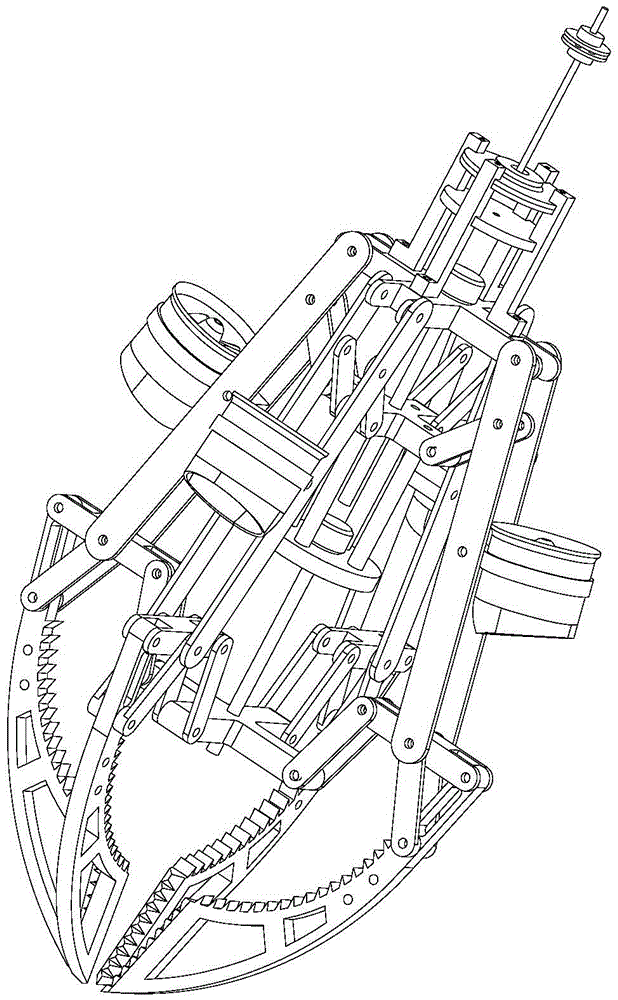

[0045] There are two pairs of four grabbing mechanisms, and the distance between adjacent grabbing mechanisms is 90°. Two grabbing mechanisms in every pair of grabbing mechanisms are arranged symmetrically; each grabbing mechanism includes a mechanical arm 201 positioned above and a mechanical claw 202 positioned below, the upper end of the mechanical arm 201 is hinged on the frame 1, and the mechanical claw 202 Connected to the lower end of the mechanical arm 201; the mechanical arm is provided with a rotor unit 6. The mechanical claw 202 includes a claw body 203, a cross bar 204, and a slanting bar 205, and the claw body 203, the cross bar 204, and the slanting bar 205 are hinged to f...

Embodiment 2

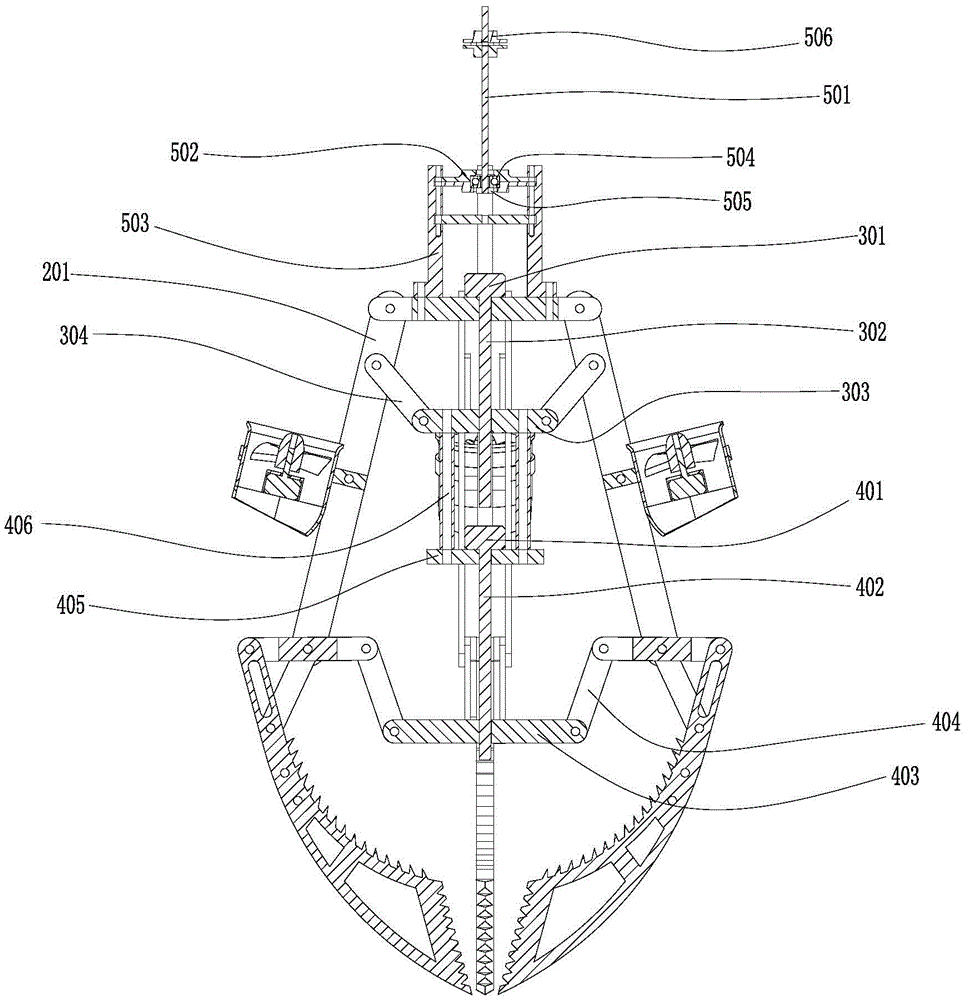

[0051] Such as Figure 6 As shown, the difference between this embodiment and embodiment 1 is:

[0052] 1. Suspension mechanism 6 includes a buffer 601, an upper connector 602, a lower connector 603, and an upper support plate; the upper support plate is located above the frame, and is fixedly connected with the frame through an upper fixing column; the middle part of the upper support plate is fixed with For the bearing, the lower connecting piece passes through the central hole of the bearing, and a limit block is connected to the bottom of the lower connecting piece, and the limit block is located below the bearing. Buffer 601 is located between upper connector 602 and lower connector 603; the upper connector is a flexible connector (such as a rope); the lower connector 603 is a rigid connector (such as a steel bar), and the lower connector 603 includes a vertical The straight section 604 and the bent section 605 above, and the vertical section 604 and the bent section 605...

Embodiment 3

[0055] The difference between this embodiment and Embodiment 1 is that: a pressure sensor is provided on the grabbing mechanism to detect the pressure used when grabbing objects; a camera and a distance sensor are installed at the bottom of the center of the manipulator device to facilitate grabbing objects .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com