High-precision 3D (three-dimensional) printer

A 3D printer, high-precision technology, applied in the direction of additive processing, etc., can solve the problems of deviation between displacement and predetermined displacement, difficulty in stabilizing tension, and unreliable sample preparation of parts, so as to avoid errors, ensure driving speed and power, and improve The effect of print accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

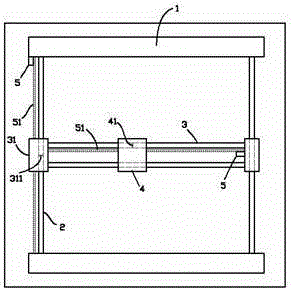

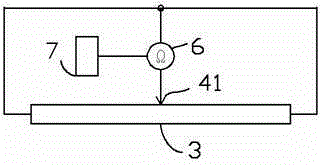

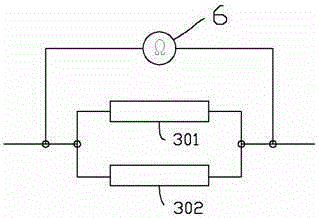

[0015] exist figure 1 In the shown embodiment, the high-precision 3D printer includes a frame 1, on which two vertical guide rails 2 parallel to each other are horizontally assumed; seat 31; two parallel transverse guide rails 3 are fixed on the guide rail seat 31, and the transverse guide rail 3 is orthogonal and spans between the two longitudinal guide rails 2; The nozzle base 4 that the horizontal guide rail moves; the printer also includes a horizontal drive mechanism that makes the nozzle base 4 slide along the horizontal guide rail 3, and a longitudinal drive mechanism that makes the horizontal guide rail seat 31 slide along the longitudinal guide rail 2, the horizontal, The longitudinal drive mechanism includes a stepper motor 5 and a transmission belt 51; the surface of one of the transverse guide rails 3 is made of a resistive material, and the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com