Automatic safe take-up wheel

A take-up wheel, a safe technology, applied in the field of electric power, can solve problems such as taking a long time and not pulling the wire smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

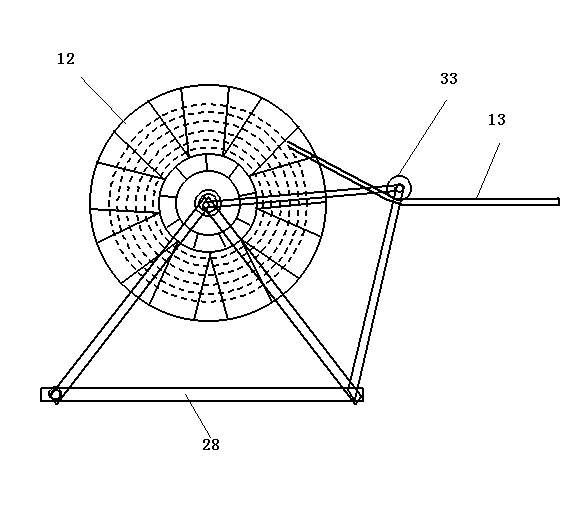

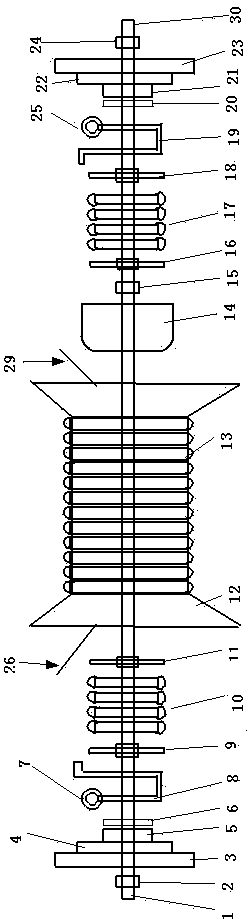

[0016] figure 2 It is an exploded view of the structure in the rotating shaft of the present invention. In the figure, the left and right parts of the wire wheel 12 are actually assembled on the central shaft 1 or 30 inside the center sleeve of the wire wheel 12. The fixed barrel 14 is located in the middle of the wire wheel, and the right end of the fixed barrel 14 is provided with a limit bolt 15. The left and right parts of other components are arranged symmetrically. The following is a summary between the left and right parts of each component. The number is the part on the left, and the number behind it is the part on the right. What middle position is provided with is barrel 14, is provided with spring in barrel 14, plays the dynamic effect of automatic winding cable, and one end of spring is fixedly connected on the central shaft, and the other end is fixed together with wire wheel 12, Close to the two ends of the barrel and the limit screw, there are symmetrically ar...

Embodiment 2

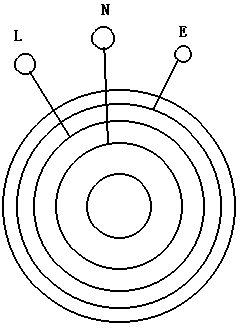

[0021] image 3 is a schematic diagram of a contact ring on one side of a multiphase cable. Ring-shaped point contact wires are arranged on the contact ring (6 or 20), respectively connected to the three-phase lines N, L, and E of the cable.

[0022] Figure 4 It is a schematic diagram of the contact between the three-phase U-shaped copper strip and the contact ring. When the three-phase line is connected to the three U-shaped copper strips set on one side, three mutually insulated concentric contacts need to be set. In this embodiment They are three copper strips: copper strip one 8a or 19a, copper strip two 8b or 19b, copper strip three 8c or 19c, and the copper strips are separated by insulating spacers 32 to prevent short circuits between the three-phase circuits. The contact terminals are set on the three U-shaped copper strips, and under the action of the compression spring, they are respectively connected with the ring-shaped point contact wires on the contact ring (6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com