Assembly type prefabricated comprehensive pipe rack pipe joint connecting structure

A technology of integrated pipe gallery and connecting structure, which is applied in underwater structures, infrastructure engineering, hydraulic engineering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to clearly illustrate the technical features of the present solution, the present invention will be described in detail below through specific implementation methods and in conjunction with the accompanying drawings.

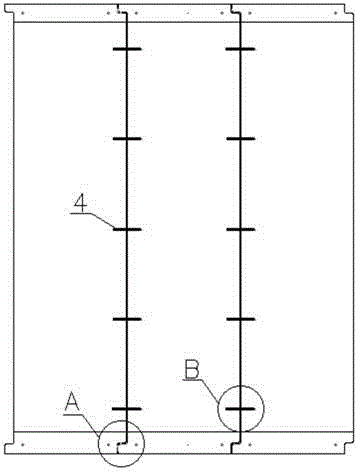

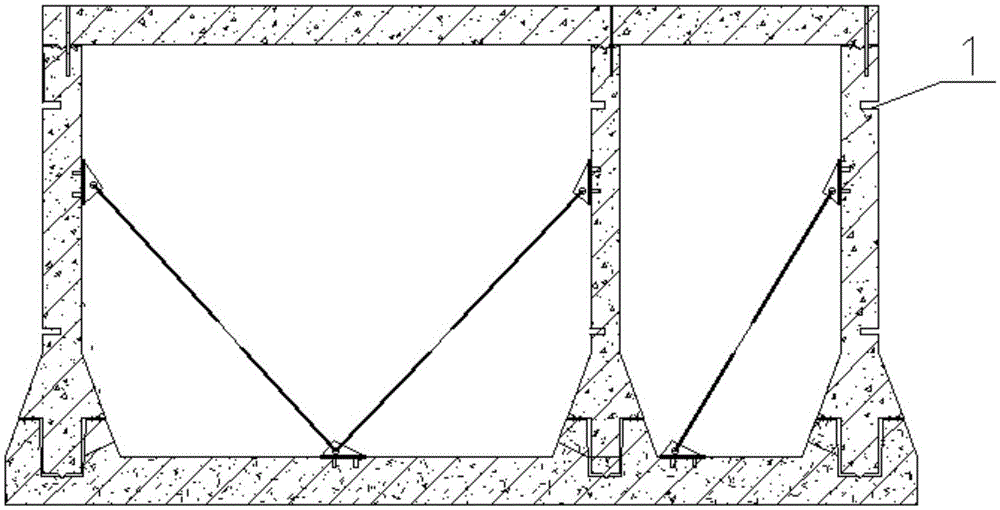

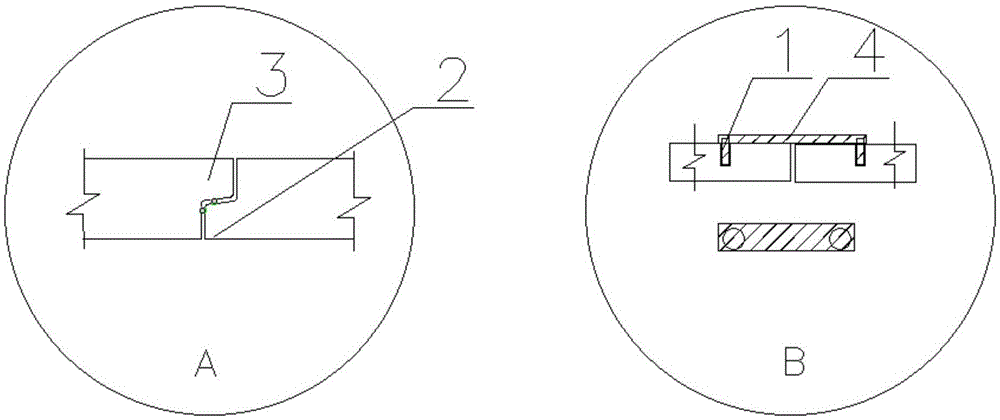

[0016] like Figure 1-3 As shown in Fig. 1, an assembled prefabricated comprehensive pipe gallery pipe joint connection structure, the pipe joint surface of the pipe gallery is provided with pre-embedded anchoring steel bars 1 at intervals, and the adjacent pipe joints are docked through the docking and guiding function of the pipe joint socket 3 and the socket 2, using The adjacent pipe joints are fastened to the puller 4 to form a continuous pipe gallery, combined with the 5 waterproof sealing structures at the socket of the pipe joints to form a reliable, safe and stable continuous pipe gallery.

[0017] The above specific implementation manners cannot be regarded as limiting the protection scope of the present invention. For those skilled in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com