Replaceable beam-column joint earthquake damage control device

A technology for earthquake damage and control devices, which is applied in the direction of earthquake resistance, building components, building structures, etc., can solve the problems that cannot be quickly replaced or repaired, requires high processing technology precision, and consumes a lot of money, and achieves a simple and reliable structure. Effect of quick replacement, reduced vibration response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

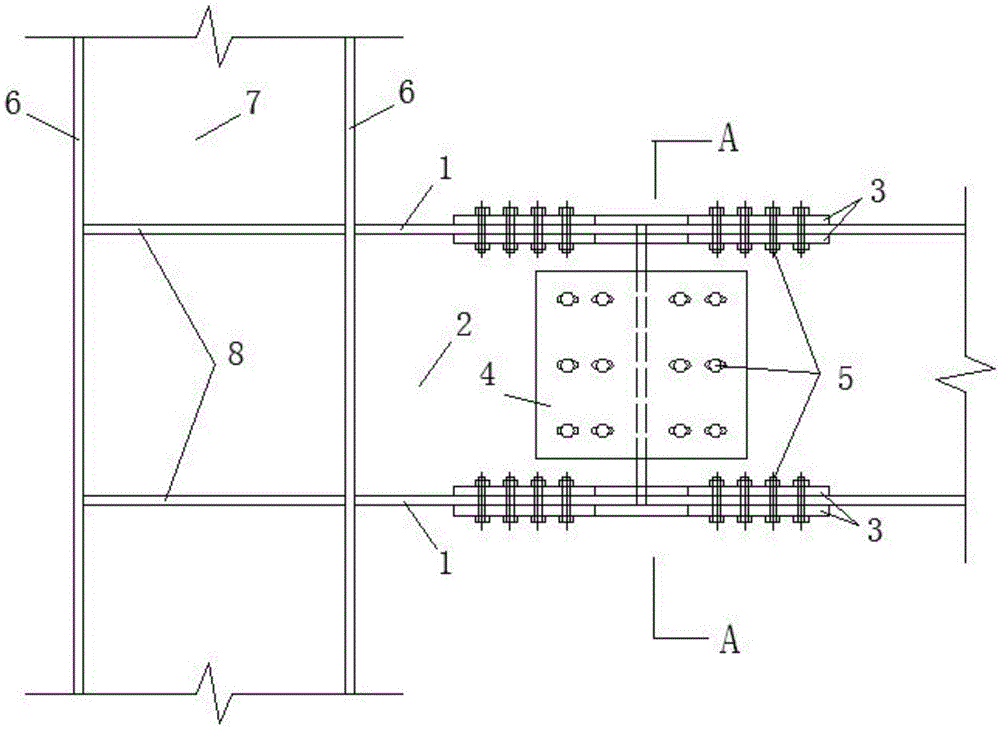

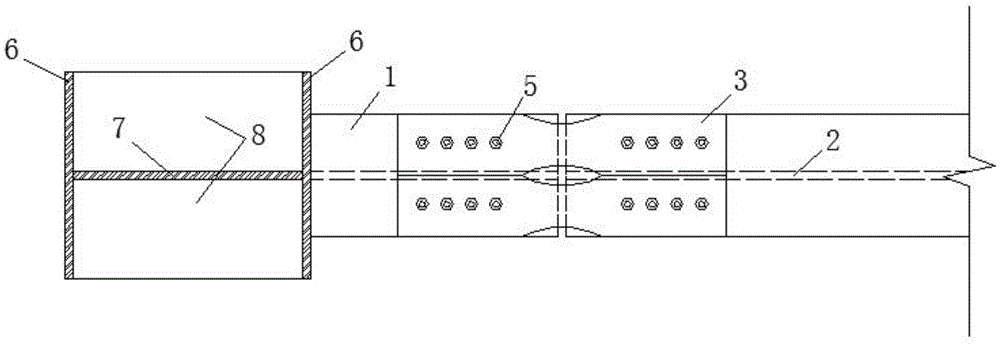

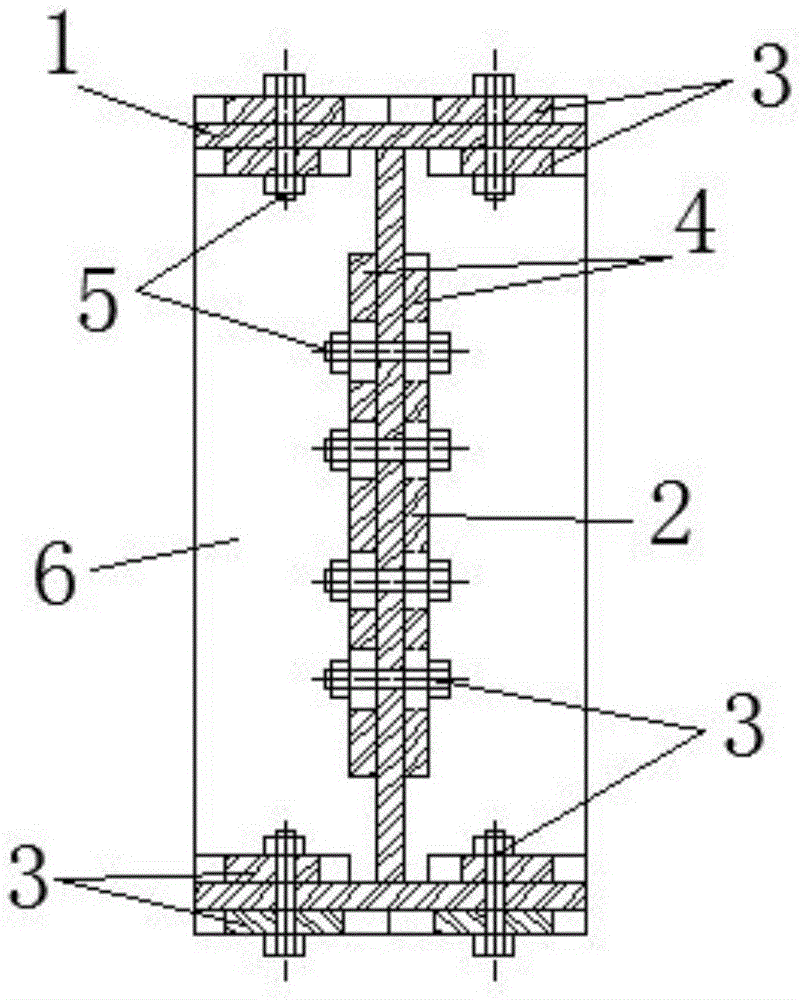

[0021] figure 1 Installation diagram for the replaceable beam-column joint seismic damage control device of the present invention Figure 1 , figure 2 for figure 1 top view of image 3 for figure 1 A-A sectional view, such as Figure 1-Figure 3 As shown, the replaceable seismic damage control device for beam-column joints provided by the present invention includes: a flange energy-dissipating fuse 3, and the flange energy-dissipating fuse 3 is arranged between the connecting gaps of two beam flange plates 1, and the beam flange Flange energy-dissipating fuses 3 are respectively arranged on the upper and lower sides of the plate 1, and bolt holes are arranged on the flange energy-dissipating fuses.

[0022] The present invention can be a beam-column joint of ordinary steel structure or high-strength steel structure, and the flange energy-dissipating fuse 3 is made of ordinary-strength steel or low-yield-point steel, which has good ductility and energy dissipation capacity...

Embodiment 2

[0033] Figure 6 Installation diagram for the replaceable beam-column joint seismic damage control device of the present invention Figure II , On the basis of Embodiment 1, a concrete floor slab 9 is added. The concrete floor slab 9 is poured in situ, and the cooperative work of the two is guaranteed through the shear studs 10 .

[0034] This embodiment is applicable to nodes with floor connections, such as residences. After an earthquake, due to the protection of the cast-in-place concrete slab 9, the energy-dissipating fuse 3 on the upper flange will generally not be damaged, and only the energy-dissipating fuse at the bottom of the beam needs to be replaced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com