Magnetic control valve for air suspension seat lift

A magnetic control and air suspension technology, applied in valve details, multi-way valves, valve devices, etc., can solve problems such as loss of competitiveness, large space occupation, complex structure, etc., to solve low accuracy and high failure rate, High adaptive damping performance, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

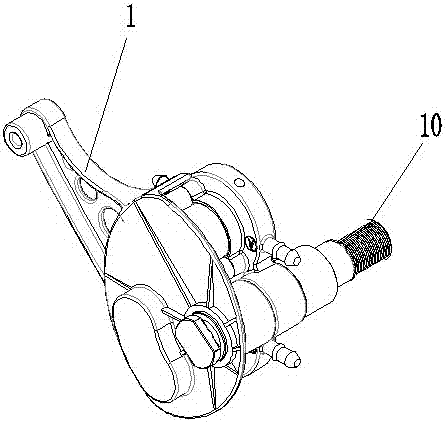

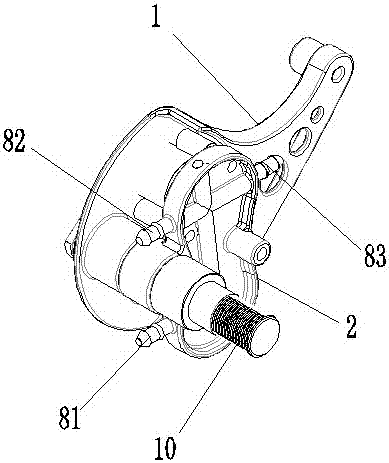

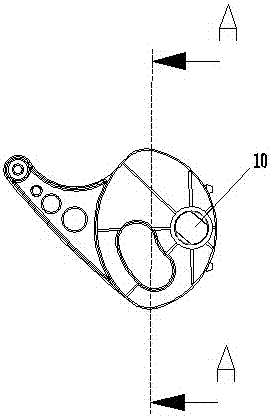

[0029] refer to Figure 1-5 , a magnetically controlled air valve for lifting and lowering an air suspension seat, which includes a valve seat 2, an intake valve body 31 and an exhaust valve body 32 fixed on the valve seat, and a transmission control arm 1;

[0030] The intake valve body 31 is equipped with an intake valve core 41 and a first spring 51. The front end of the intake valve body 31 is closed, and the rear end is sealed with the valve seat. The two ends of the first spring 51 respectively act on the intake valve core. 41 and the intake valve body 31, the valve seat 2 is provided with the first air inlet and the first air outlet that cooperate with the intake valve core 41;

[0031] The exhaust valve body 32 is equipped with an exhaust valve core 42 and a second spring 52, the front end of the exhaust valve body 32 is closed, the rear end is sealed with the valve seat, and the two ends of the second spring 52 respectively act on the exhaust valve core. 42 and the e...

Embodiment 2

[0045] refer to Image 6 , different from Embodiment 1, the grooves of this embodiment include a first groove 91 and a second groove 92, and the permanent magnetic alloy block includes a first permanent magnetic alloy block 61 and a second permanent magnetic alloy block 62, the first permanent magnetic alloy block 61 is installed in the first groove 91, the second permanent magnetic alloy block 62 is installed in the second groove 92, the center distance between the intake valve core 41 and the exhaust valve core 42 greater than the center distance between the first permanent magnetic alloy block 61 and the second permanent magnetic alloy block 62 . The first permanent magnetic alloy block 61 and the second permanent magnetic alloy block 62 are cylindrical.

[0046] The reason why two cylindrical permanent magnetic alloy blocks 61 and 62 are provided is that the production cost of the waist-shaped permanent magnetic alloy block is relatively high, while the production cost of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com