Continuous laying and water-saving pressure testing construction method of long-distance water pipe

A technology for long-distance water delivery and pipeline pressure testing, which is applied to pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc., to achieve the effects of ensuring continuity, reducing water consumption for pressure testing, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] A construction method for continuous laying of long-distance water pipelines and water-saving pressure testing, characterized in that it includes the following steps:

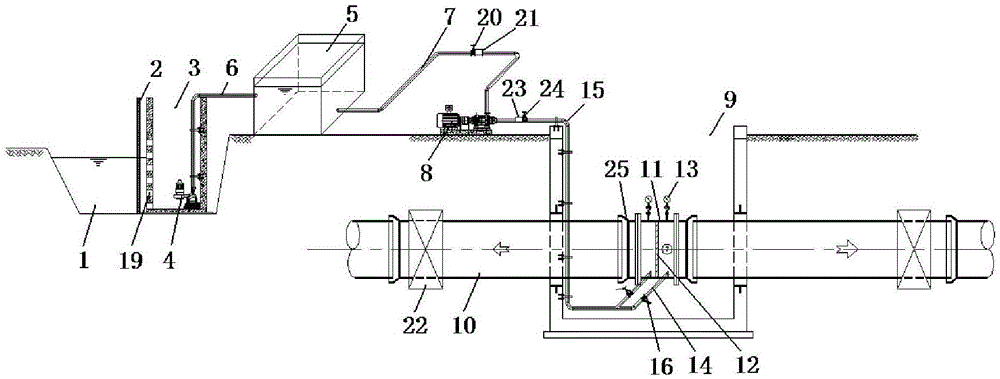

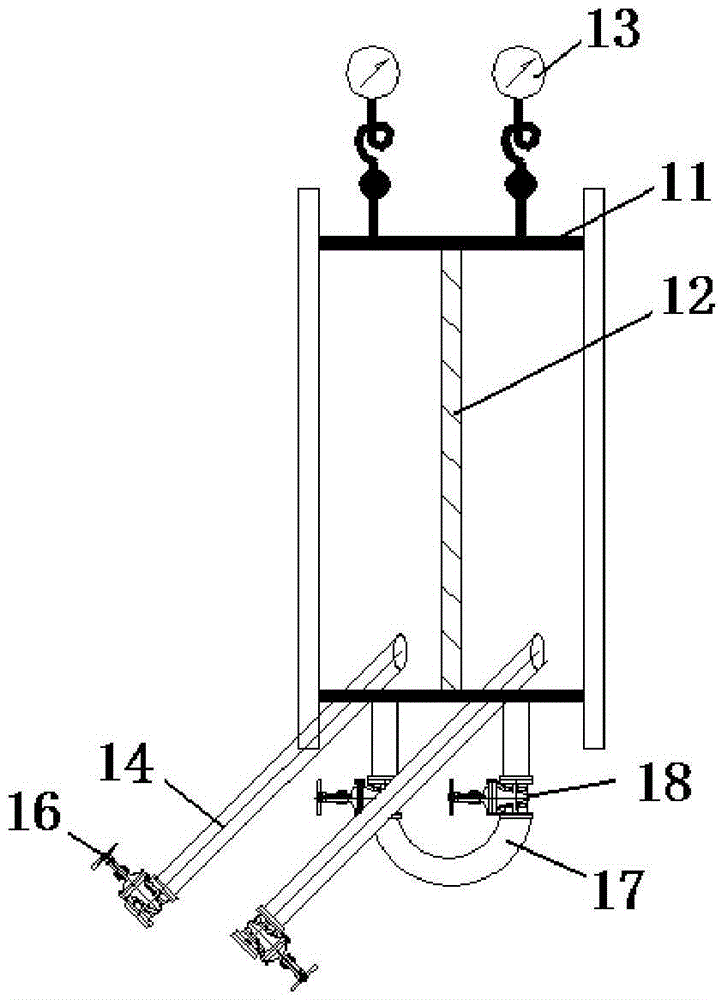

[0052] (1) Design and manufacture of prefabricated pipeline pressure test devices, such as figure 1 , figure 2 as shown, figure 1 , figure 2 Middle, 1: pool, 2: steel mesh, 3: seepage well, 4: submersible sewage pump, 5: water tank, 6: water supply pipe, 7: water delivery pipe, 8: irrigation pump, 9: valve well, 10: flexible interface Water pipeline, 11: Steel pipe in assembled device, 12: Partition plate in assembled device, 13: Pressure gauge, 14: Branch pipe, 15: Irrigation pipe, 16: First check valve, 17: Connecting pipe, 18: Second check valve, 19: Seepage hole, 20: First gate valve, 21: Third check valve, 22: Drag pier, 23: Fourth check valve, 24: Second gate valve, 25: Bearing plate Short tube;

[0053] (1.1) Design of prefabricated pipeline pressure test device:

[0054] Familiar with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com