Consistency compensation method and apparatus for resistance strain type weighing sensor

A weighing sensor and resistance strain type technology, applied in the field of sensors, can solve problems such as complex formulas, inaccurate compensation, and easy calculation of wrong results, and achieve the effect of improving accuracy and simplifying the compensation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

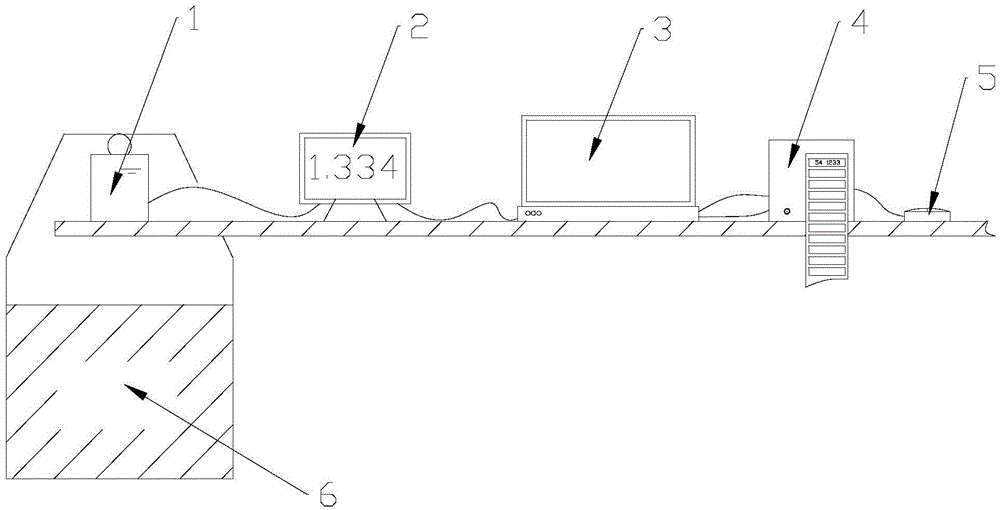

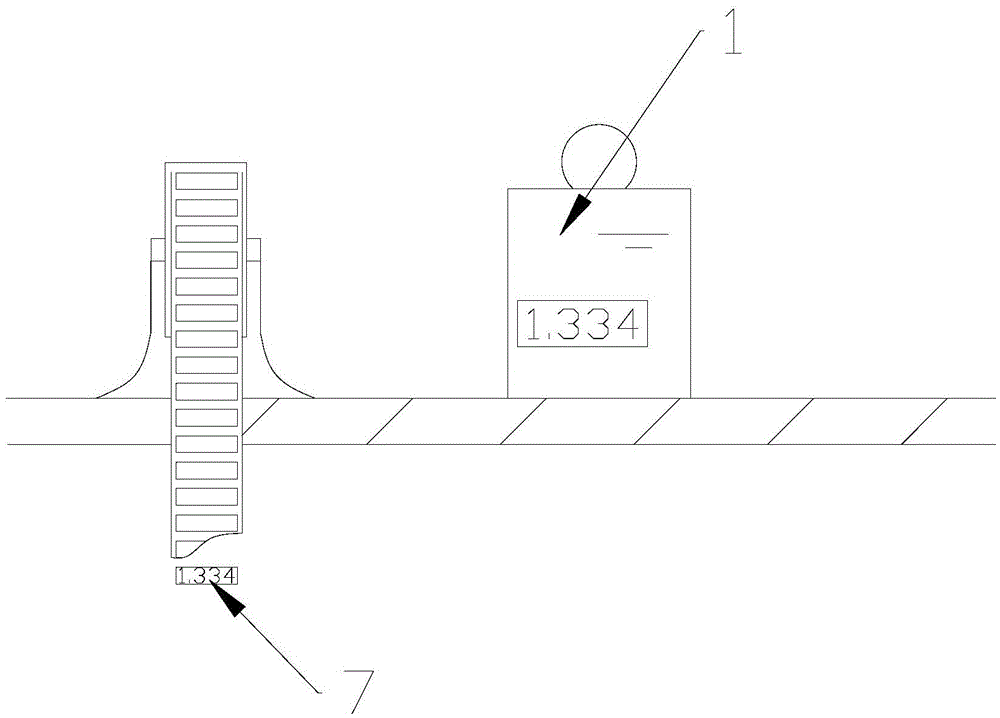

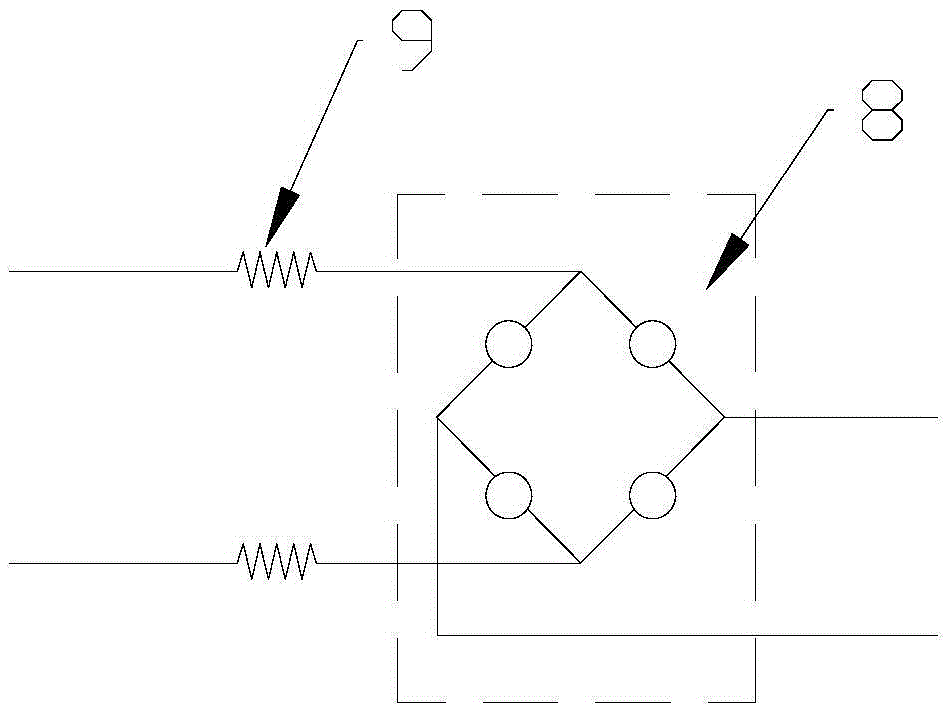

[0052] Please refer tofigure 1 , figure 2 and image 3 , Embodiment 1 of the present invention is:

[0053] A method for consistency compensation of a resistance strain sensor, comprising:

[0054] First, the tester applies a full load of weight to the sensor 1 on the dynamometer, which can be achieved by applying a weight 6. After the output of the sensor 1 is stable, the sensitivity measuring instrument 2 connected to it displays the sensitivity of the sensor 1 before compensation; and the data Sent to the arithmetic unit 3 that is connected with it, the preferred arithmetic unit 3 is a computer; By setting the communication protocol between the sensitivity measuring instrument 2 and the computer, a communication transmission channel is established to realize the detected sensitivity of the sensitivity measuring instrument output and Input the impedance value into the computer, such as setting the communication protocol parameters of the sensitivity measuring instrument 2...

Embodiment 2

[0059] Please refer to figure 1 , figure 2 and image 3 , the second embodiment of the present invention is:

[0060] A resistance strain type load cell consistency compensation device, comprising a resistance strain type load cell 1, a sensitivity measuring instrument 2, an arithmetic unit 3 and a printer connected in sequence; the arithmetic unit 3 can be a computer; the compensation device also It includes a trigger device 5 connected to a computer, which is used to trigger the computer to start the calculation process, and the trigger device 5 is preferably a foot switch; the resistance strain type load cell is used to obtain a full load of weight, and the output is stable The value of , which is the sensitivity of the sensor before compensation;

[0061] The sensitivity measuring instrument 2 is used to obtain and display the sensitivity of the sensor, and simultaneously send the sensitivity to the computer through the communication link established with the computer;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com