Patents

Literature

48 results about "Enterprise security management" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

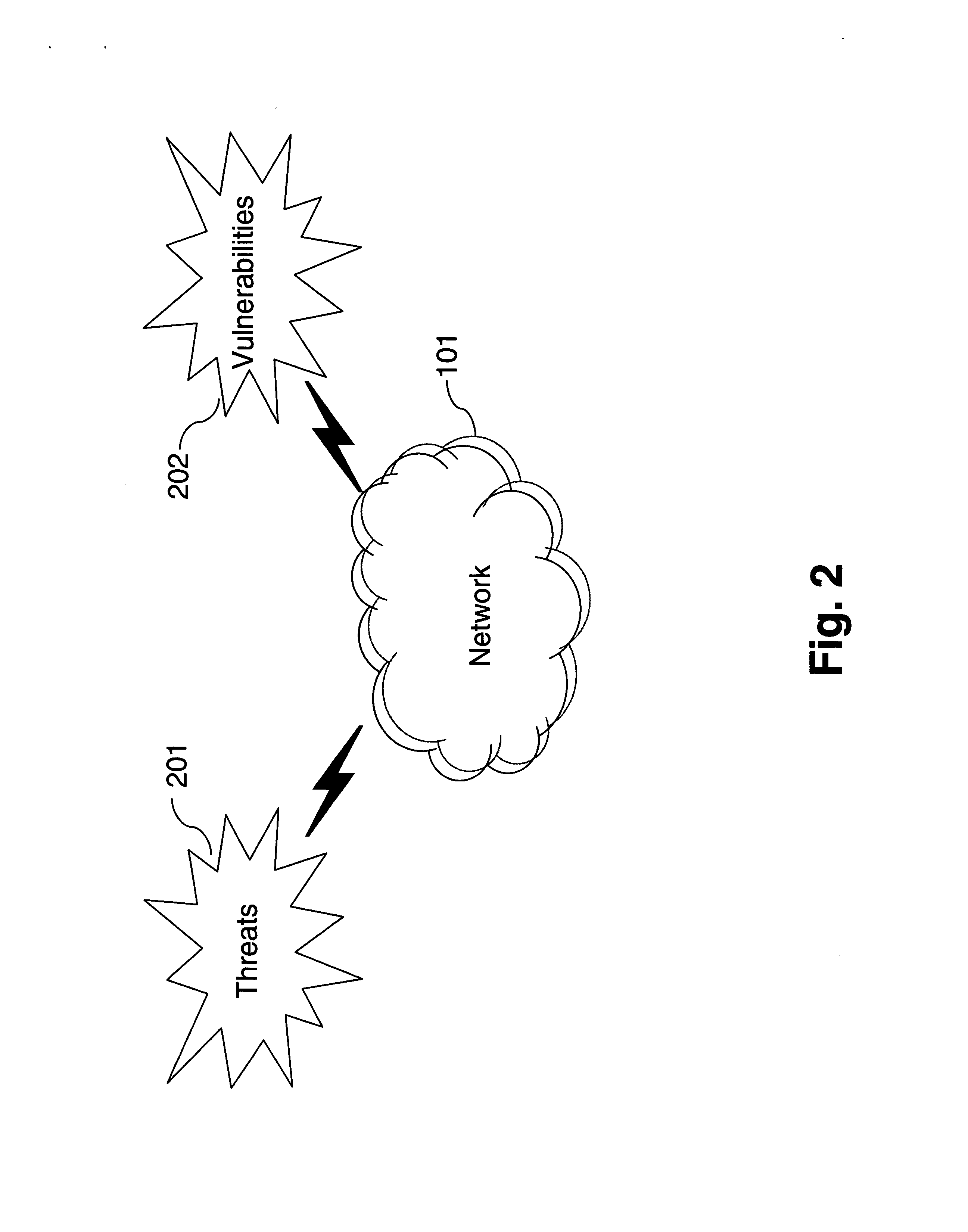

Enterprise security management for network equipment

InactiveUS20090199298A1Eliminate the problemMemory loss protectionUnauthorized memory use protectionEnterprise security managementDashboard

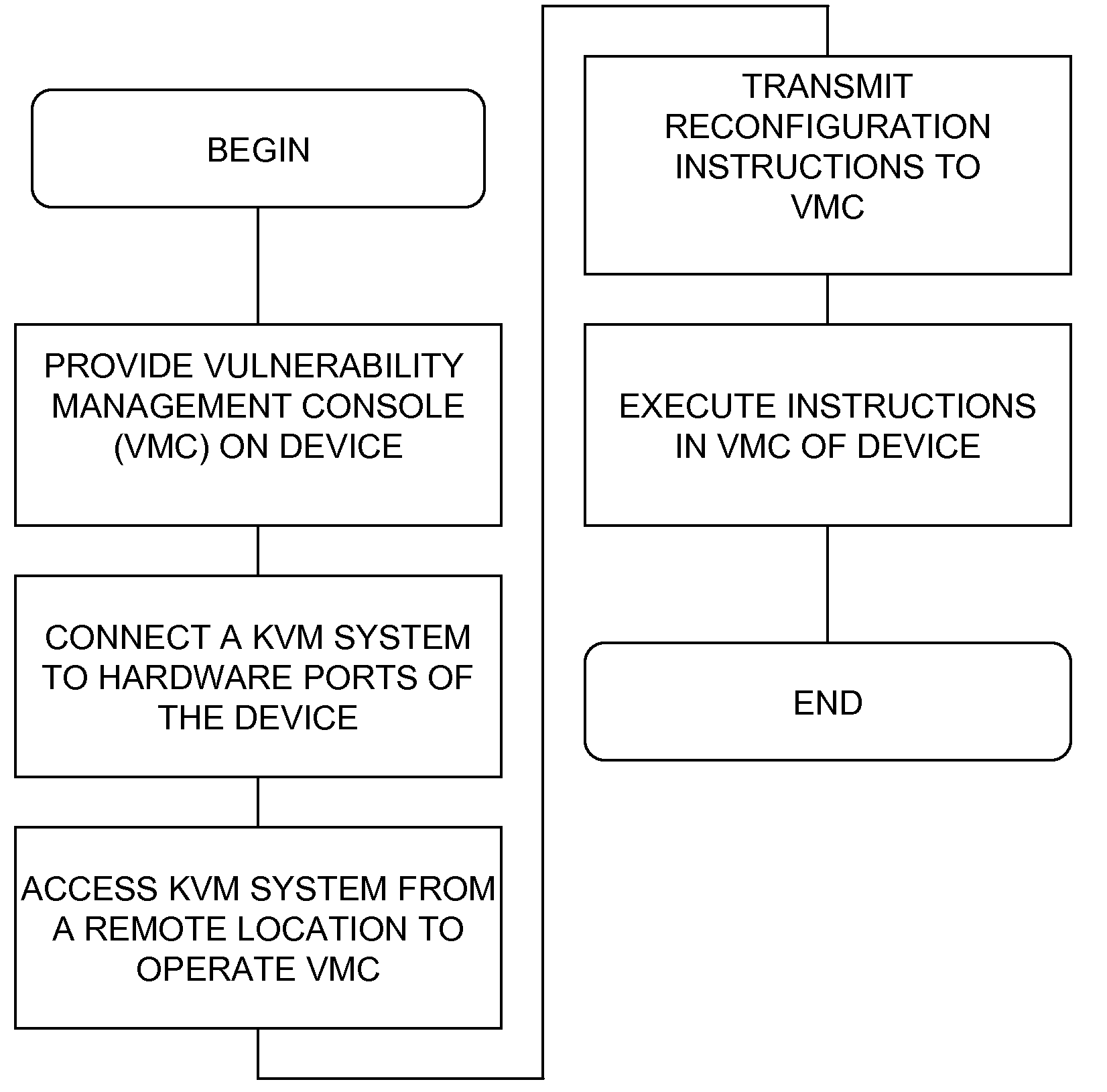

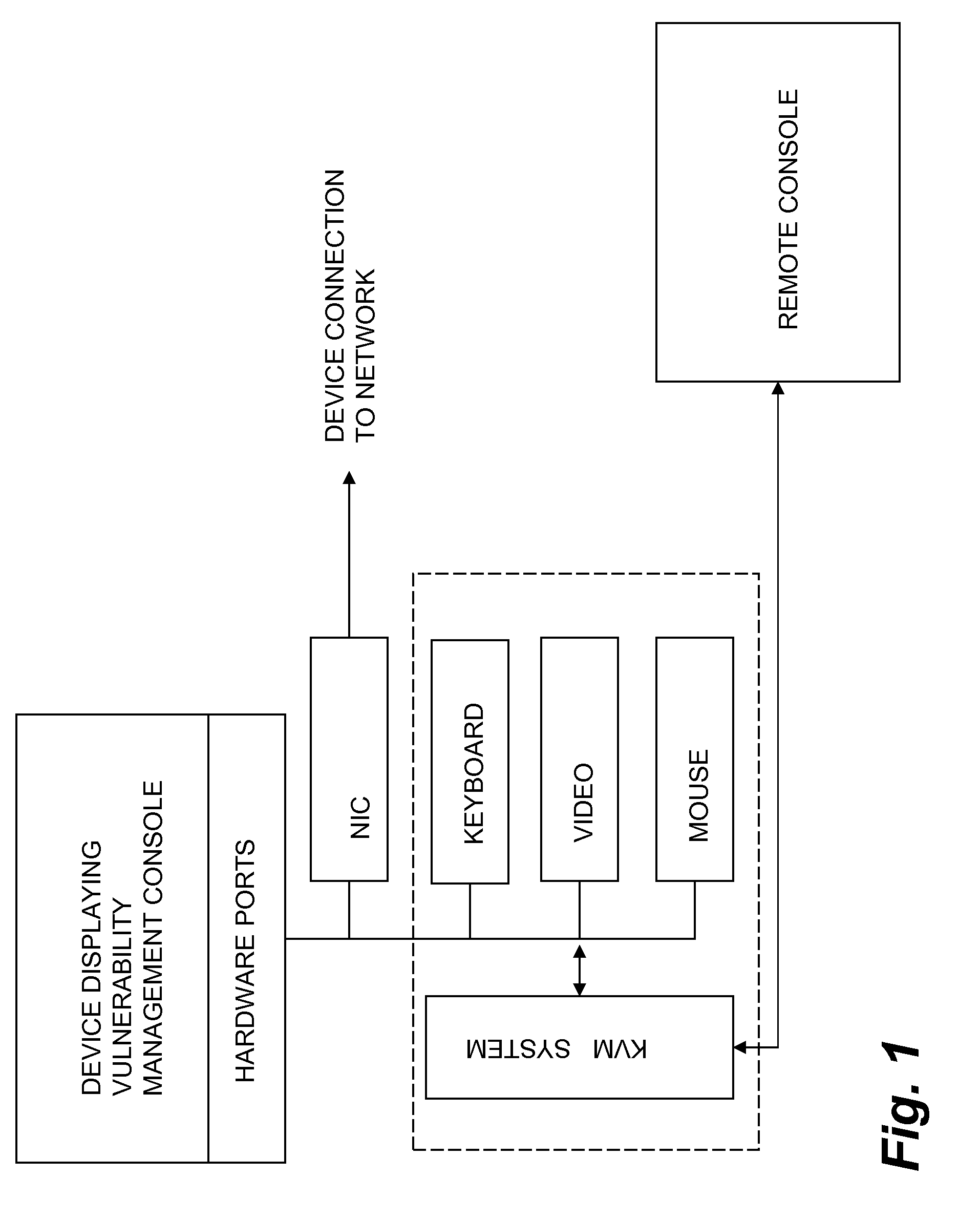

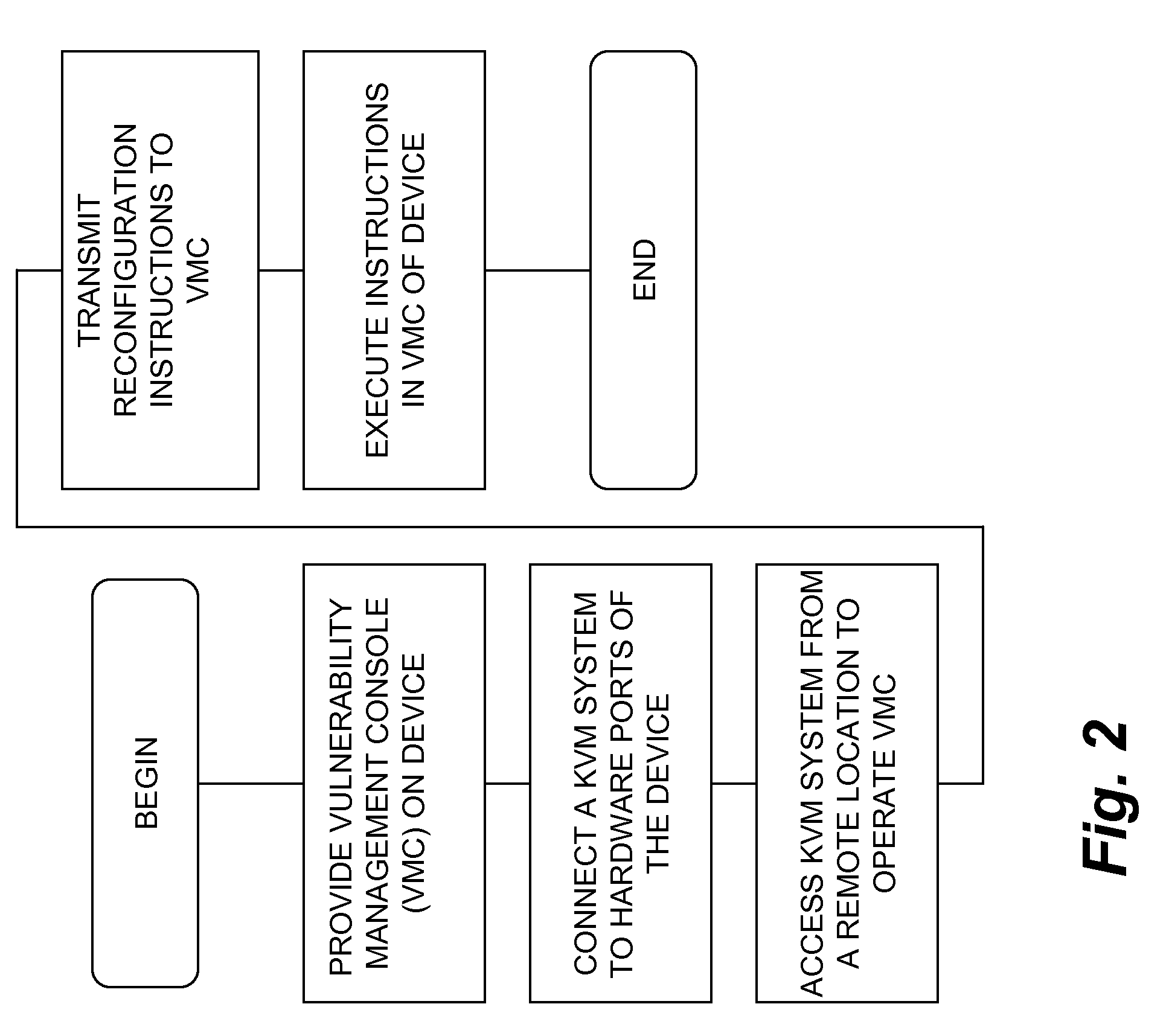

The inventive device includes a dashboard or graphical user interface (GUI), a security access control (AUTH) and secure communications sub-system (SEC-COMM), network and asset discover and mapping system (NAADAMS), an asset management engine (AME), vulnerability assessment engine (CVE-DISCOVERY), vulnerability remediation engine (CVE-REMEDY), a reporting system (REPORTS), a subscription, updates and licensing system (SULS), a countermeasure communications system (COUNTERMEASURE-COMM), a logging system (LOGS), a database integration engine (DBIE), a scheduling and configuration engine (SCHED-CONFIG), a wireless and mobile devices / asset detection and management engine (WIRELESS-MOBILE), a notification engine (NOTIFY), a regulatory compliance reviewing and reporting system (REG-COMPLY), client-side (KVM-CLIENT) integration with KVM over IP or similar network management equipment, authentication-services (KVM-AUTH) integration with KVM over IP or similar network management equipment and server-side (KVM-SERVER) integration with KVM over IP or similar network management equipment.

Owner:NETCLARITY

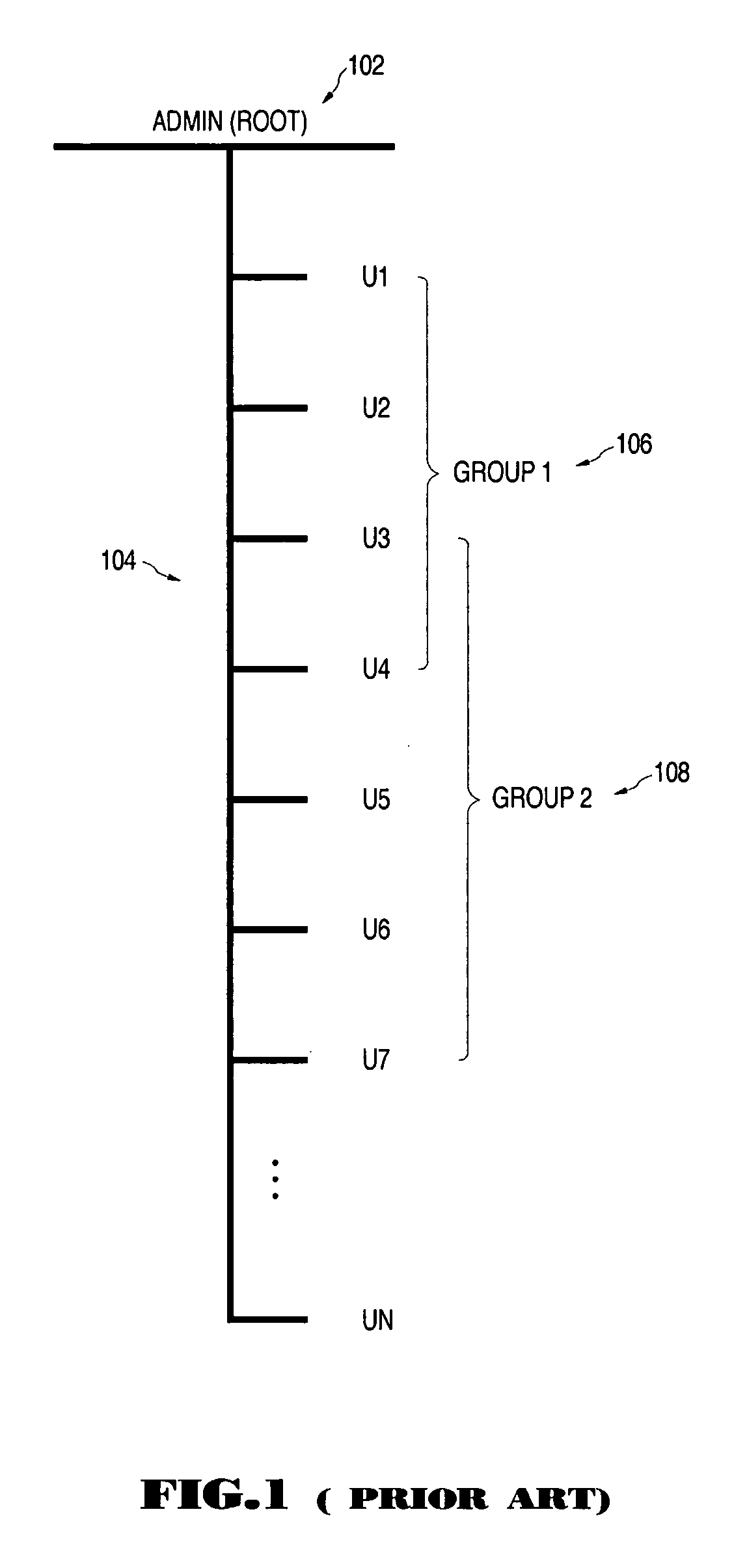

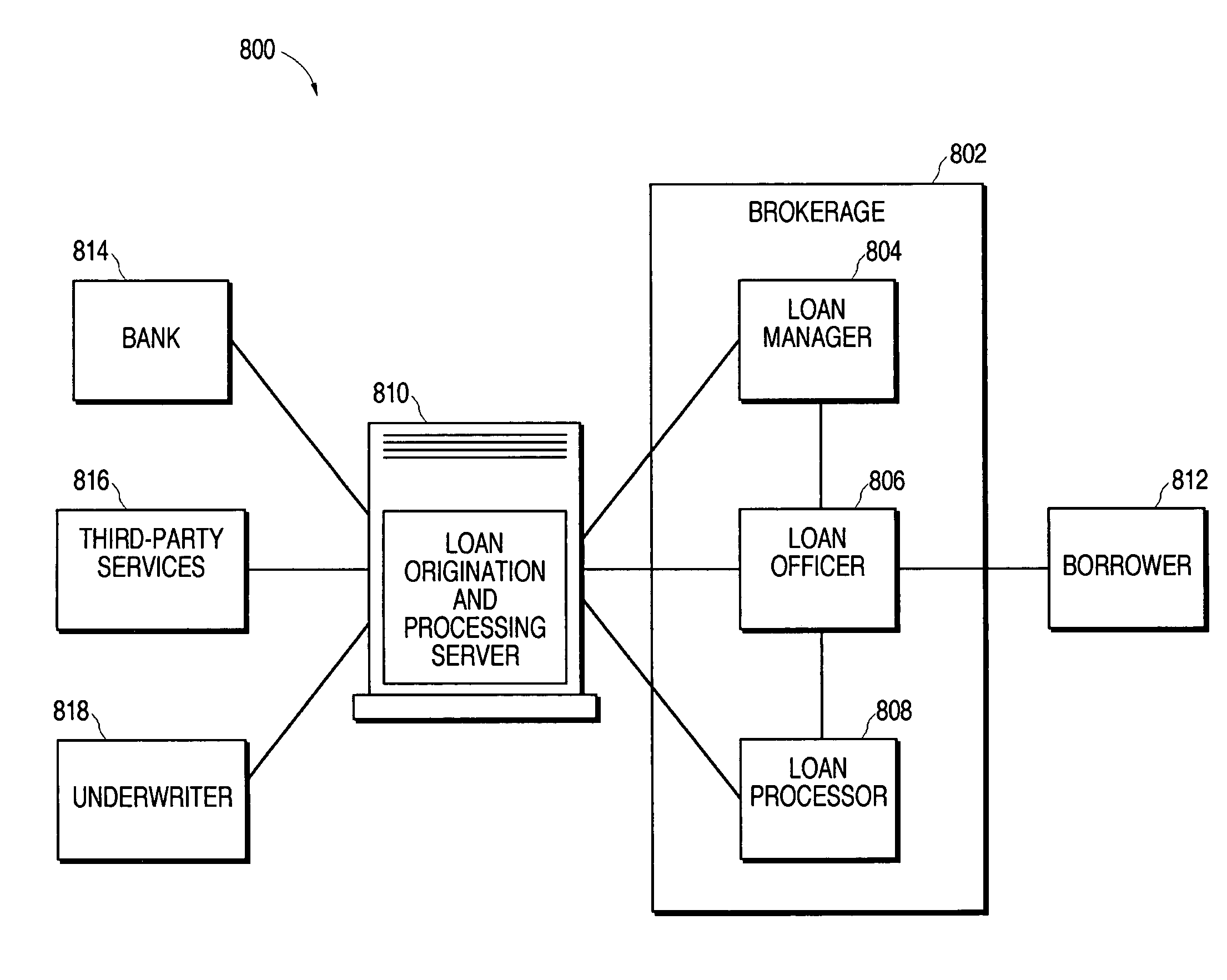

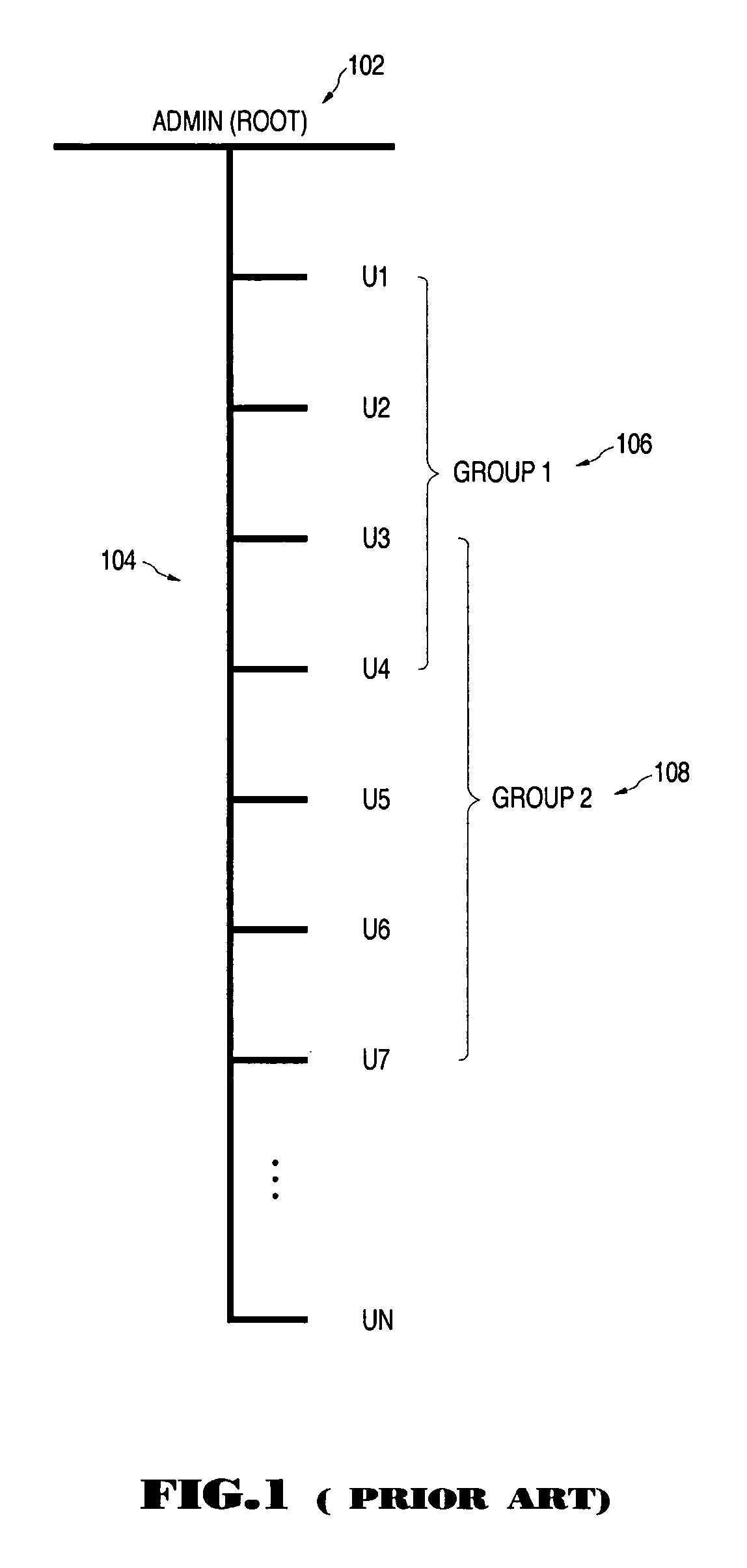

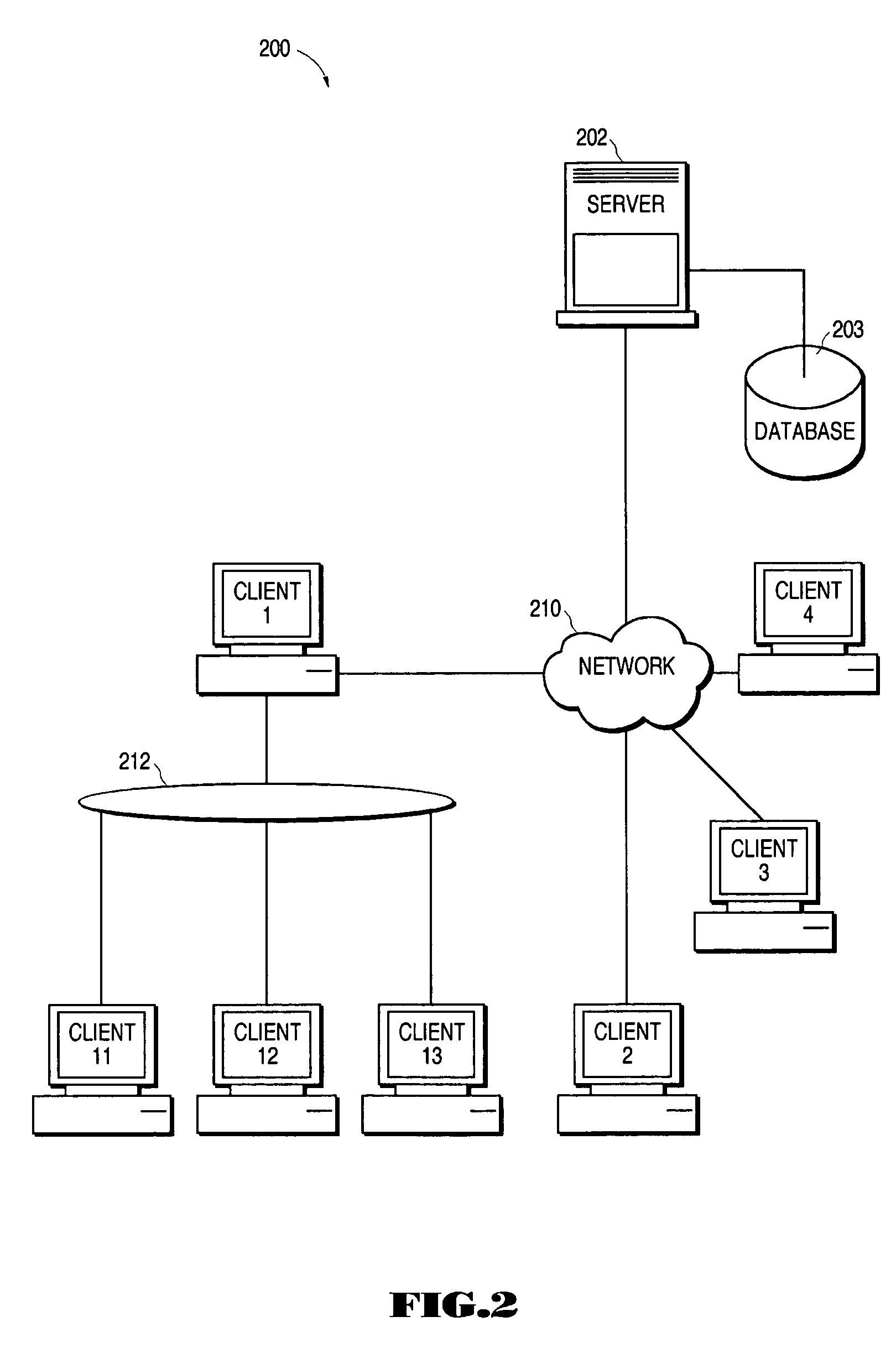

Enterprise security management system using hierarchical organization and multiple ownership structure

ActiveUS20060005036A1FinanceDigital data processing detailsEnterprise security managementComputer users

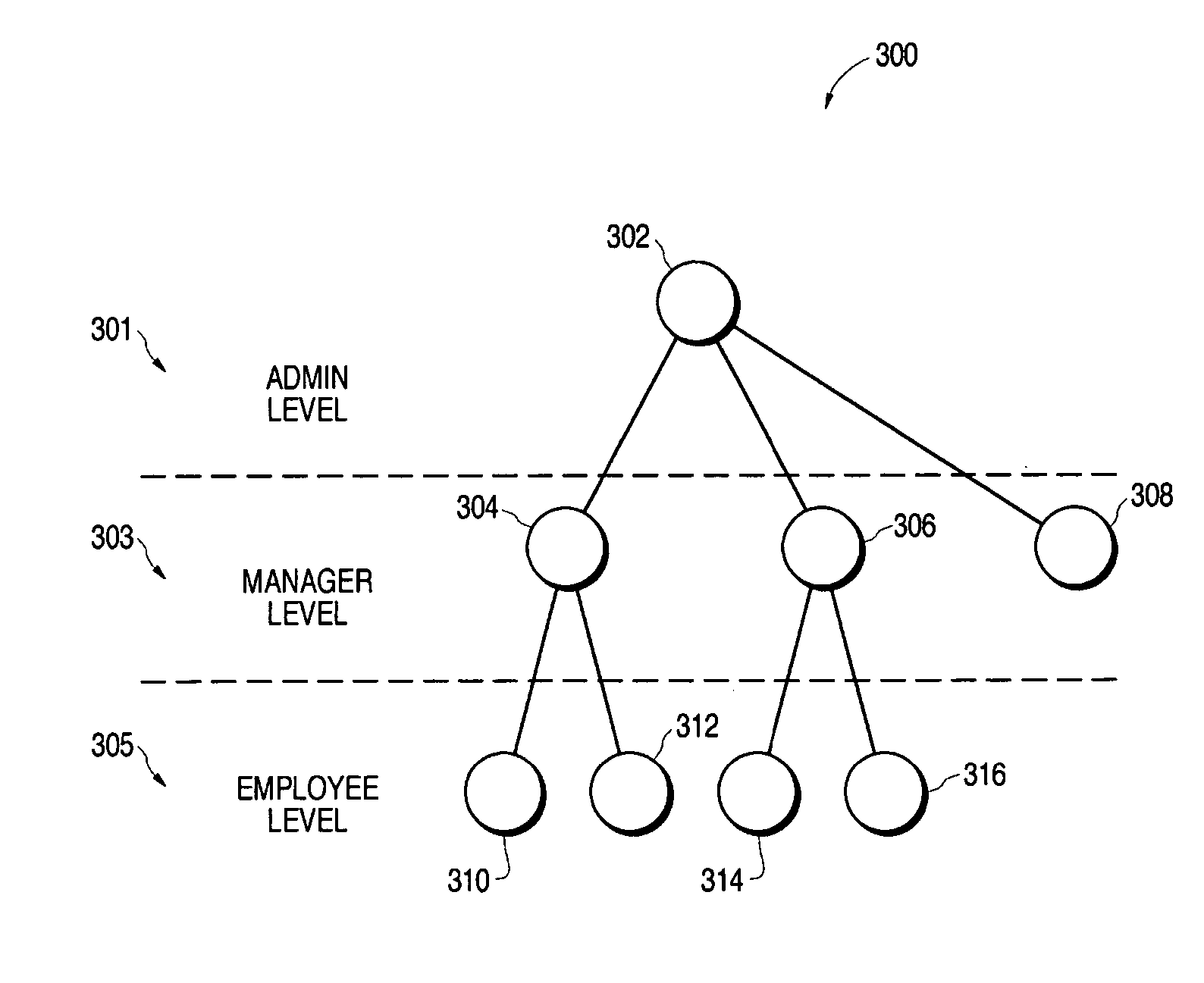

A hierarchical security model for networked computer users is described. Files and resources are controlled or created by users within the network. Each user within the network has an account that is managed by a network administrator. The account specifies the user identifier and password. Users are grouped into organizations depending upon function or other organizational parameter. The groups within the network are organized hierarchically in terms of access and control privileges. Users within a higher level group may exercise access and control privileges over files or resources owned by users in a lower level group. The account for each user further specifies the group that the owner belongs to and an identifier for any higher level groups that have access privileges over the user's group. All users within a group inherit the rights and restrictions of the group.

Owner:ICE MORTGAGE TECH INC

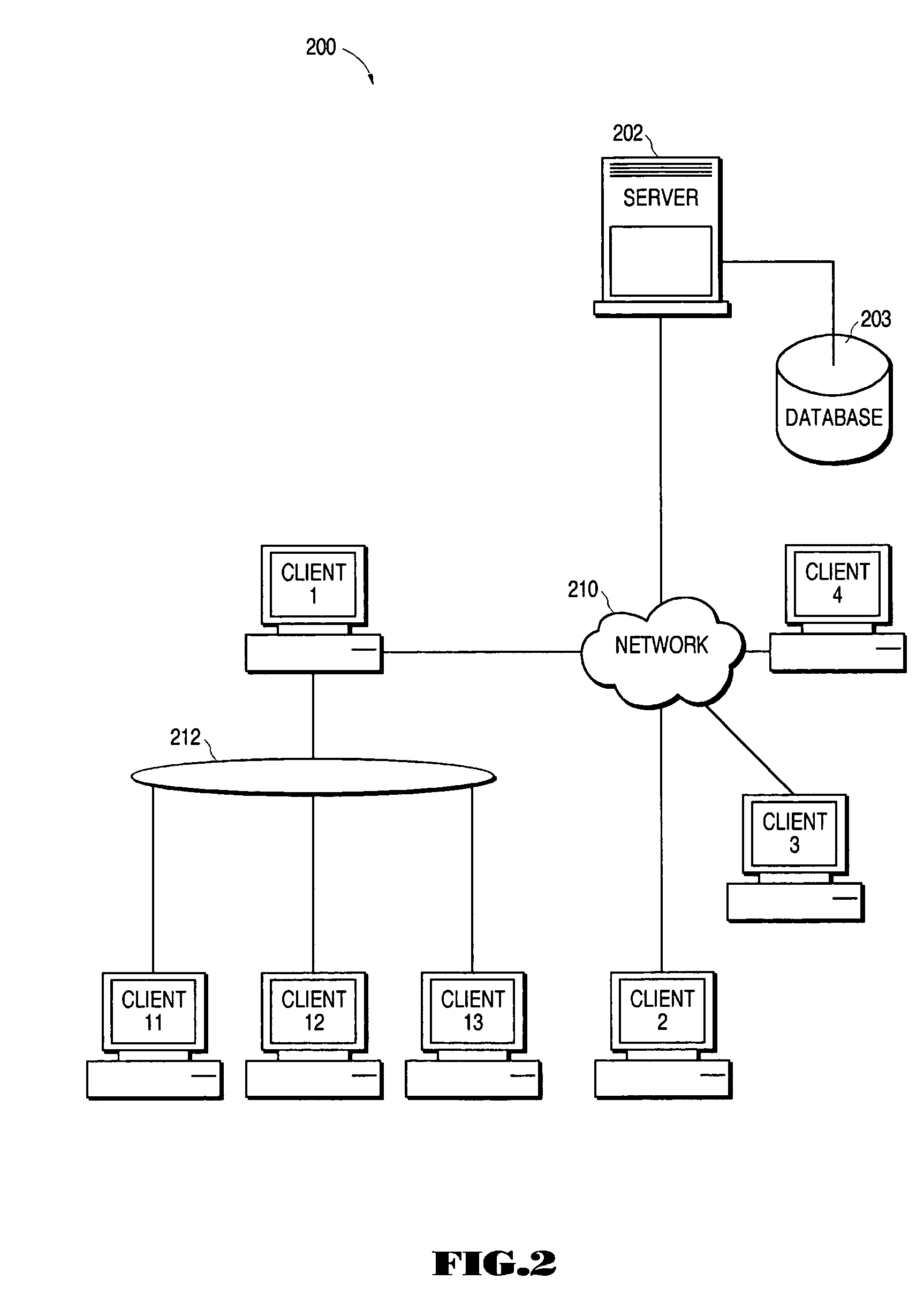

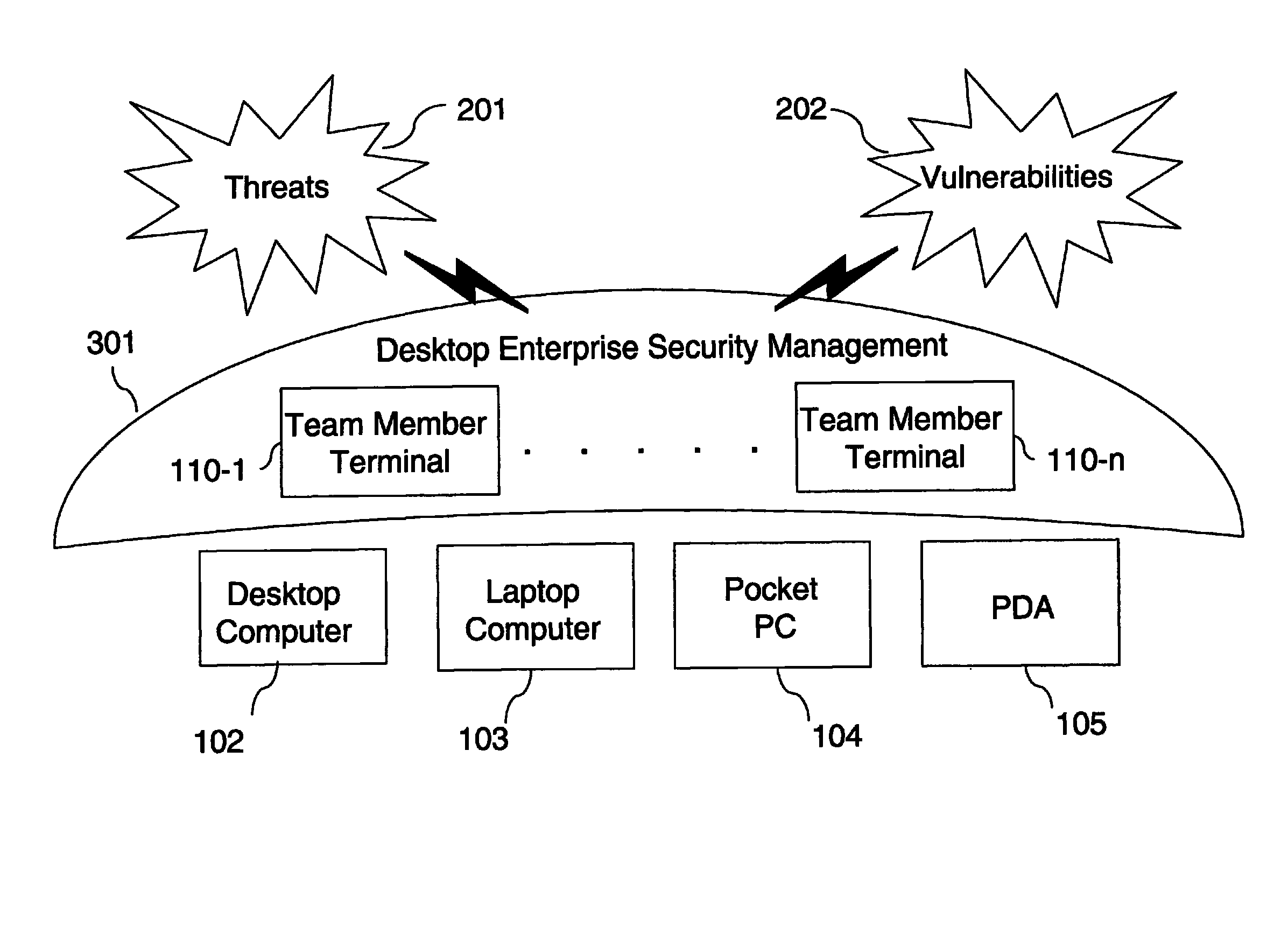

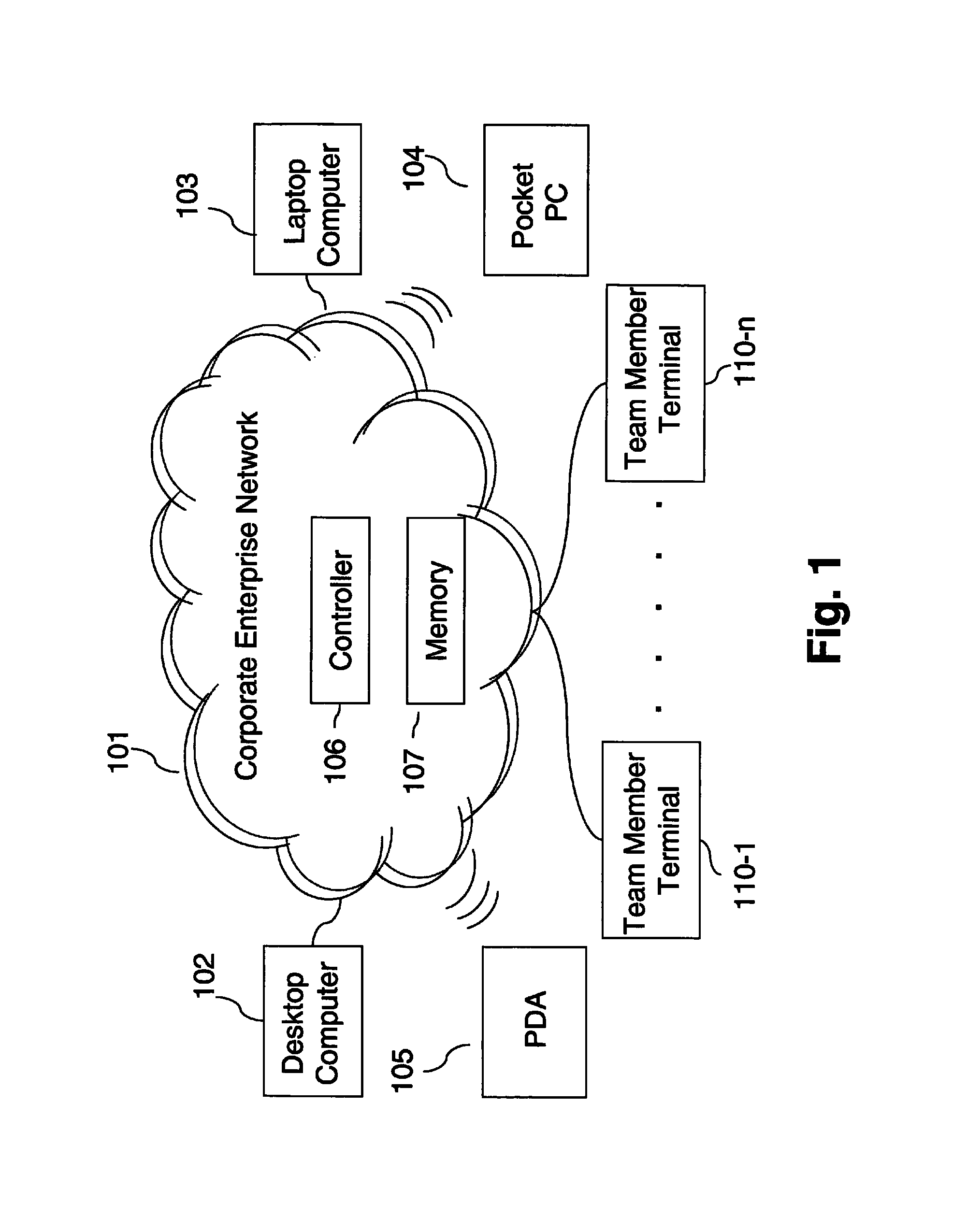

Enterprise desktop security management and compliance verification system and method

InactiveUS8499330B1Improve developmentEasy to implementDigital data processing detailsAnalogue secracy/subscription systemsEnterprise security managementNetwork security policy

A method for desktop enterprise security management that addresses the multiple network and desktop security needs of an enterprise, facilitates the development, implementation, and enforcement of the enterprise's desktop security policies and procedures, and provides for review and revision of those policies and procedures. The method is based on a four-stage approach to desktop network security management. The first stage lays the foundation for the enterprise's network security policy. The second stage validates users and desktop devices according to the enterprise's desktop security policies, gathers data, and provides feedback to users regarding their compliance with the enterprise's desktop security policies. The third stage enforces the enterprise's desktop security policies by blocking access by desktop devices and / or users that do not comply with the enterprise's desktop security policies. The fourth stage includes periodic review of the enterprise's needs so that new desktop security support teams can be identified and the enterprise's desktop security policies implemented with the new teams.

Owner:AT&T INTPROP I L P

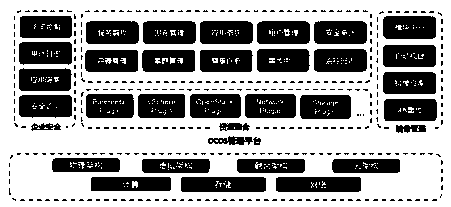

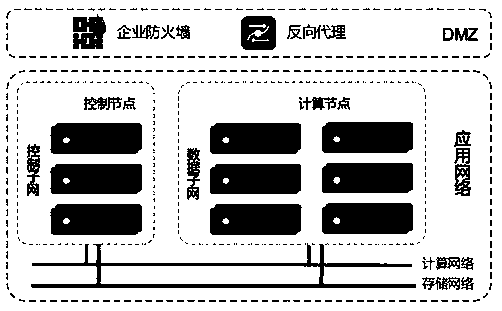

DCOS cloud management platform based on combination of Mesos and YARN

ActiveCN109803018ARealize automatic monitoringHigh availability deploymentData switching networksInformation technology support systemYarnEnterprise security management

The invention discloses a DCOS cloud management platform based on combination of Mesos and YARN. the Meso is used for managing all resources of a big data cluster; the Messos distributes resources through the resources offers; the scheduler uses the resources to run tasks on a Mesos slave server; the YARN is used for safely managing the Hadoop task; wherein the Mesos can manage resource requests of the YARN, the DCOS cloud management platform is expanded based on the Mesos and the YARN, and the DCOS cloud management platform is composed of application management, container cluster management,mirror image warehouse management, a resource integration assembly, an enterprise safety management system and a third party butt joint integration. According to the invention, the YARN can be elastically used in the shared cluster, so that the YARN is more active and elastic than that in the initial design. The capacity expansion of the whole data center becomes very easy, the Mesos and the YARNare mainly combined with relevant tasks of Hadoop big data for scheduling, the complexity of the scheduling technology is verified, and meanwhile technical support is provided for a DCOS to support big data relevant operation and big data tasks in the future.

Owner:云南电网有限责任公司信息中心

Enterprise security management system using hierarchical organization and multiple ownership structure

A hierarchical security model for networked computer users is described. Files and resources are controlled or created by users within the network. Each user within the network has an account that is managed by a network administrator. The account specifies the user identifier and password. Users are grouped into organizations depending upon function or other organizational parameter. The groups within the network are organized hierarchically in terms of access and control privileges. Users within a higher level group may exercise access and control privileges over files or resources owned by users in a lower level group. The account for each user further specifies the group that the owner belongs to and an identifier for any higher level groups that have access privileges over the user's group. All users within a group inherit the rights and restrictions of the group.

Owner:ICE MORTGAGE TECH INC

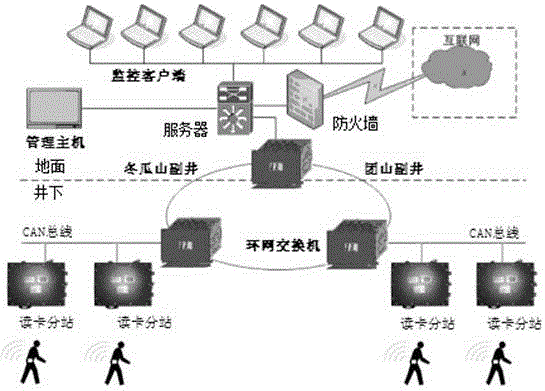

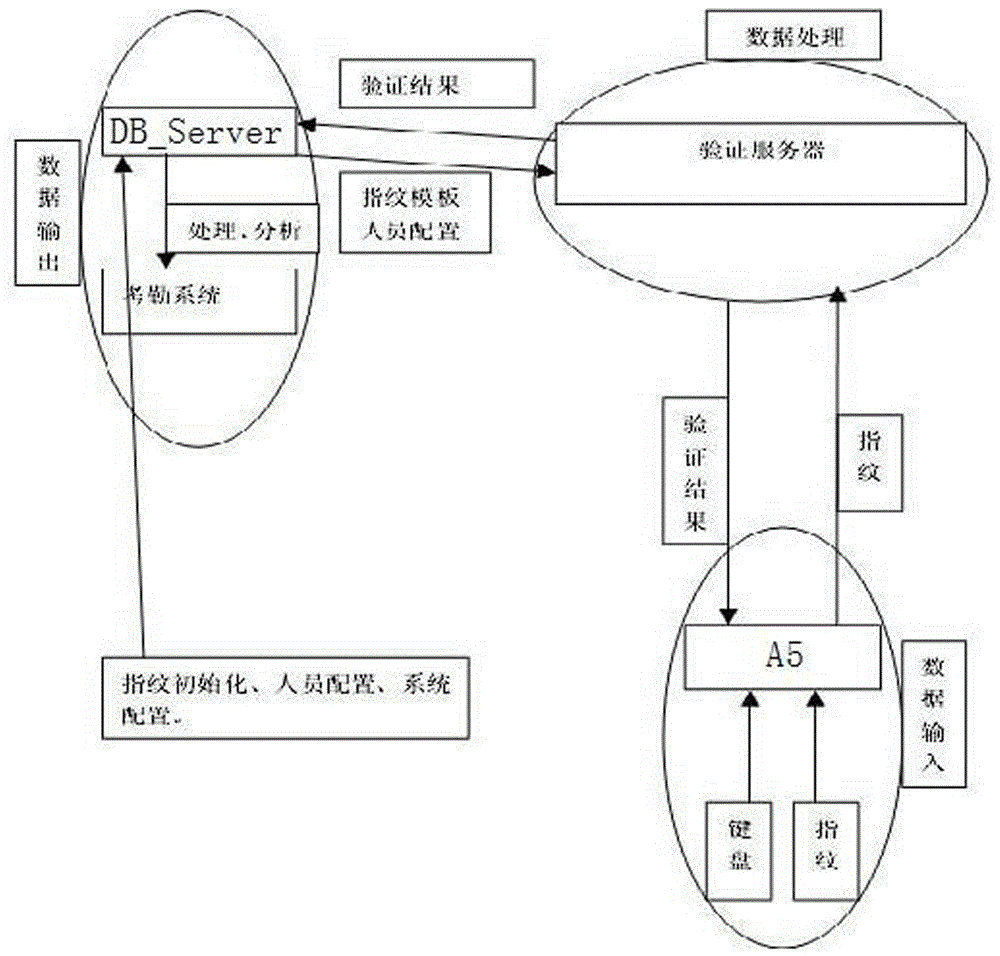

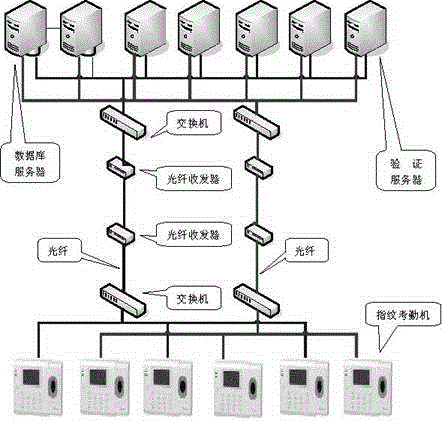

Borehole operation safety guarantee and attendance platform

InactiveCN105809759ARaise security awarenessImprove safety management levelRegistering/indicating time of eventsData processing applicationsEnterprise security managementData transmission

The invention discloses a borehole operation safety guarantee and attendance platform.A safe answering system is connected with Socket of a fingerprint verification server in a fingerprint attendance system, and connection is kept all the time; a worker presses a fingerprint on an answering machine of the safe answering system, and the safe answering system captures fingerprint data and uses the fingerprint verification server for data transmission with Socket kept in connection with the fingerprint verification server; the fingerprint verification server receives the fingerprint data and conducts fingerprint matching and judging operation, and only when answering correctly on the answering machine of the safe answering system, can the worker pass through a descending gate through the fingerprint and a location card in a borehole staff location system; after passing through the descending gate, the worker is located in real time by the borehole staff location system.The purposes of standardizing work procedures, enhancing safety protection consciousness of the worker and improving safety management level of an enterprise are achieved.

Owner:DONGGUASHAN COPPER MINE TONGLING NONFERROUS METALS GRP CO LTD

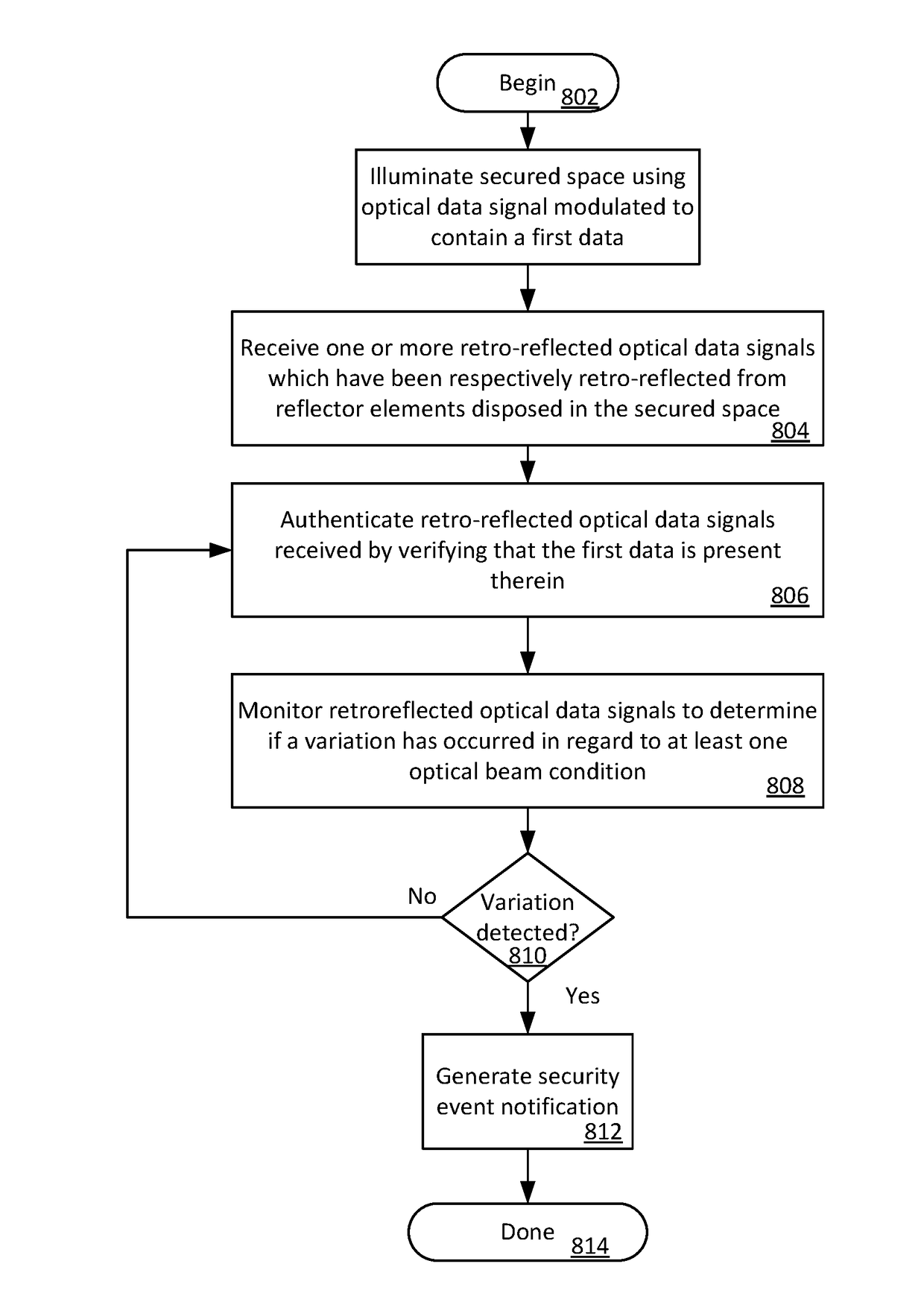

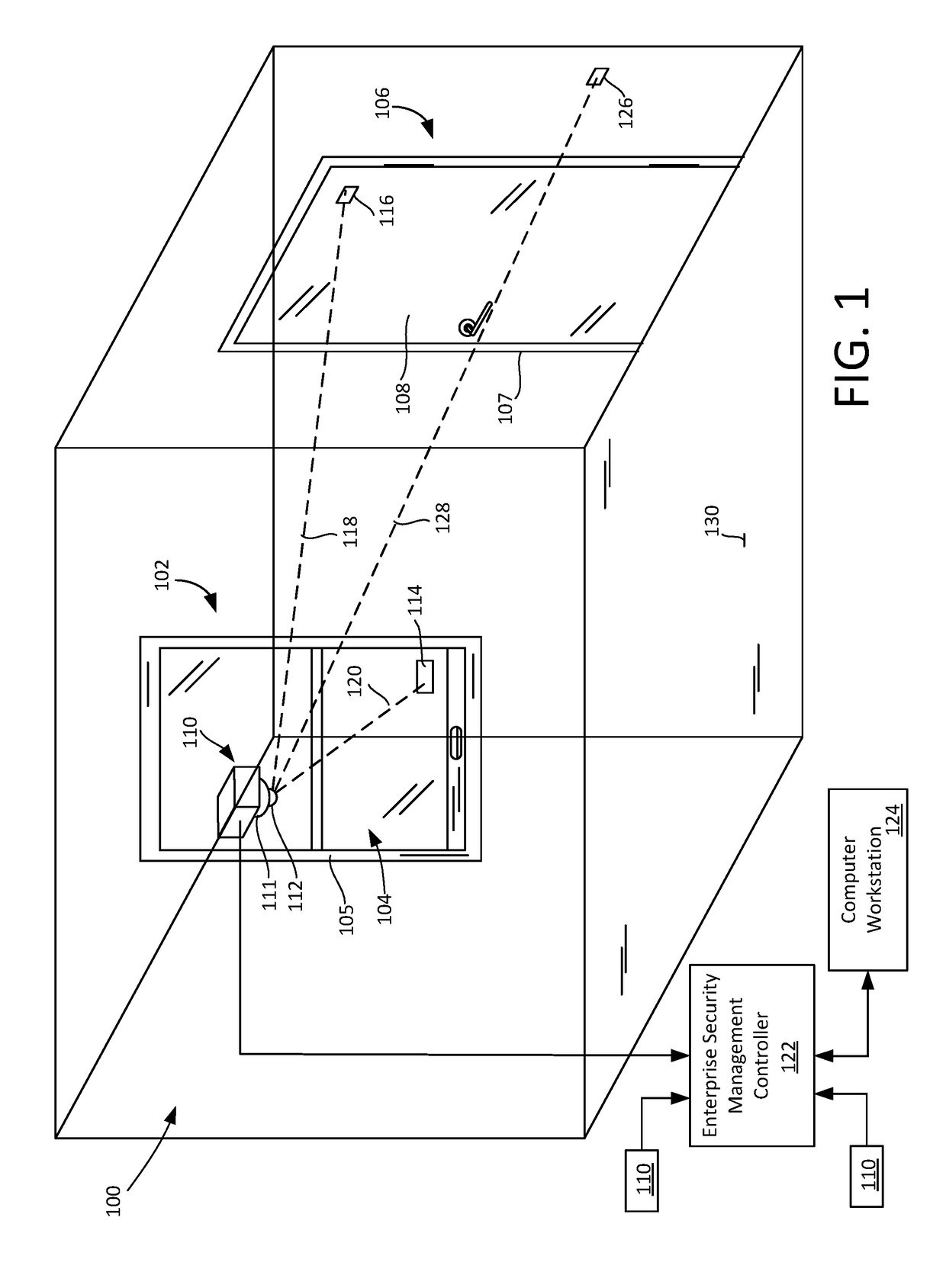

Security sensing method and apparatus

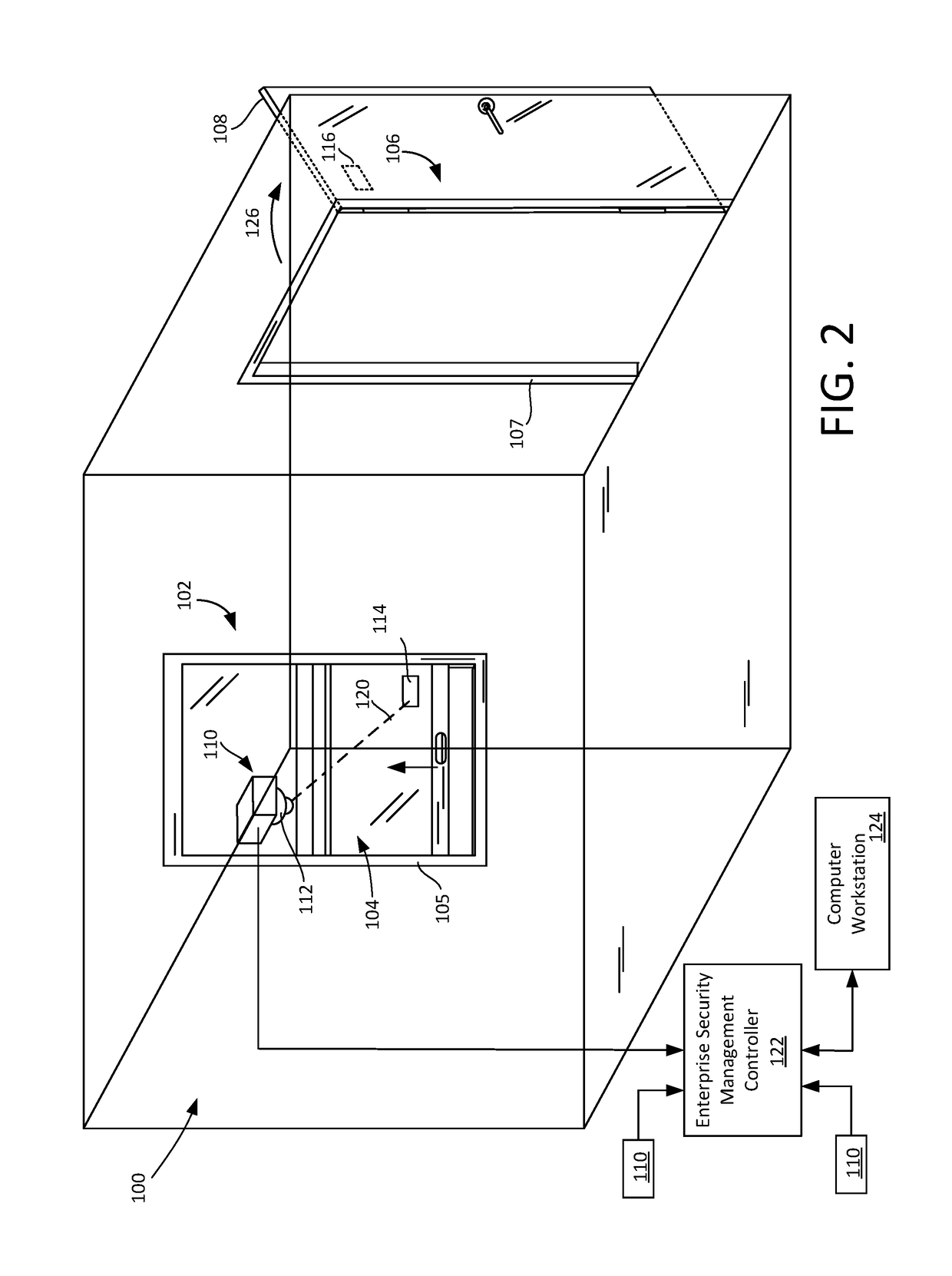

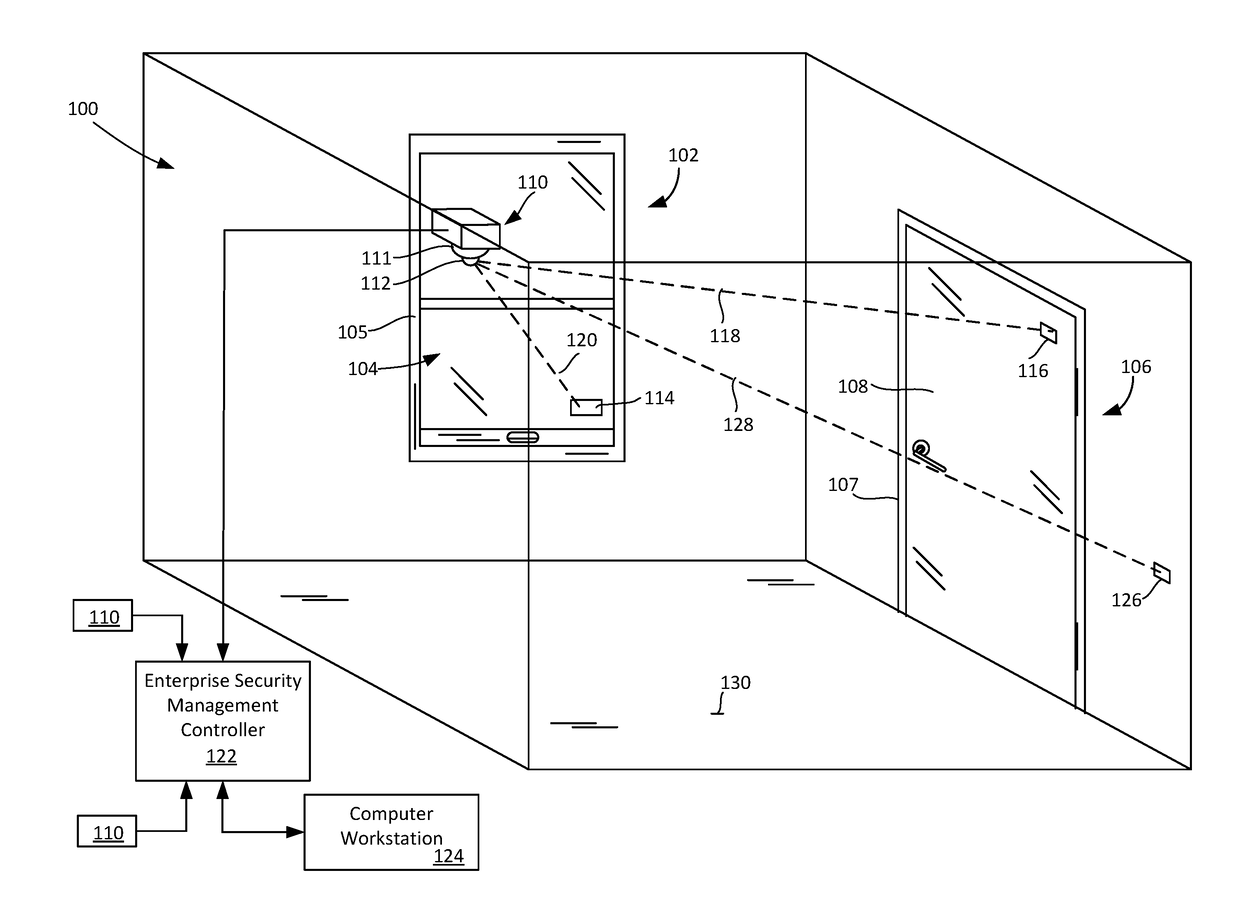

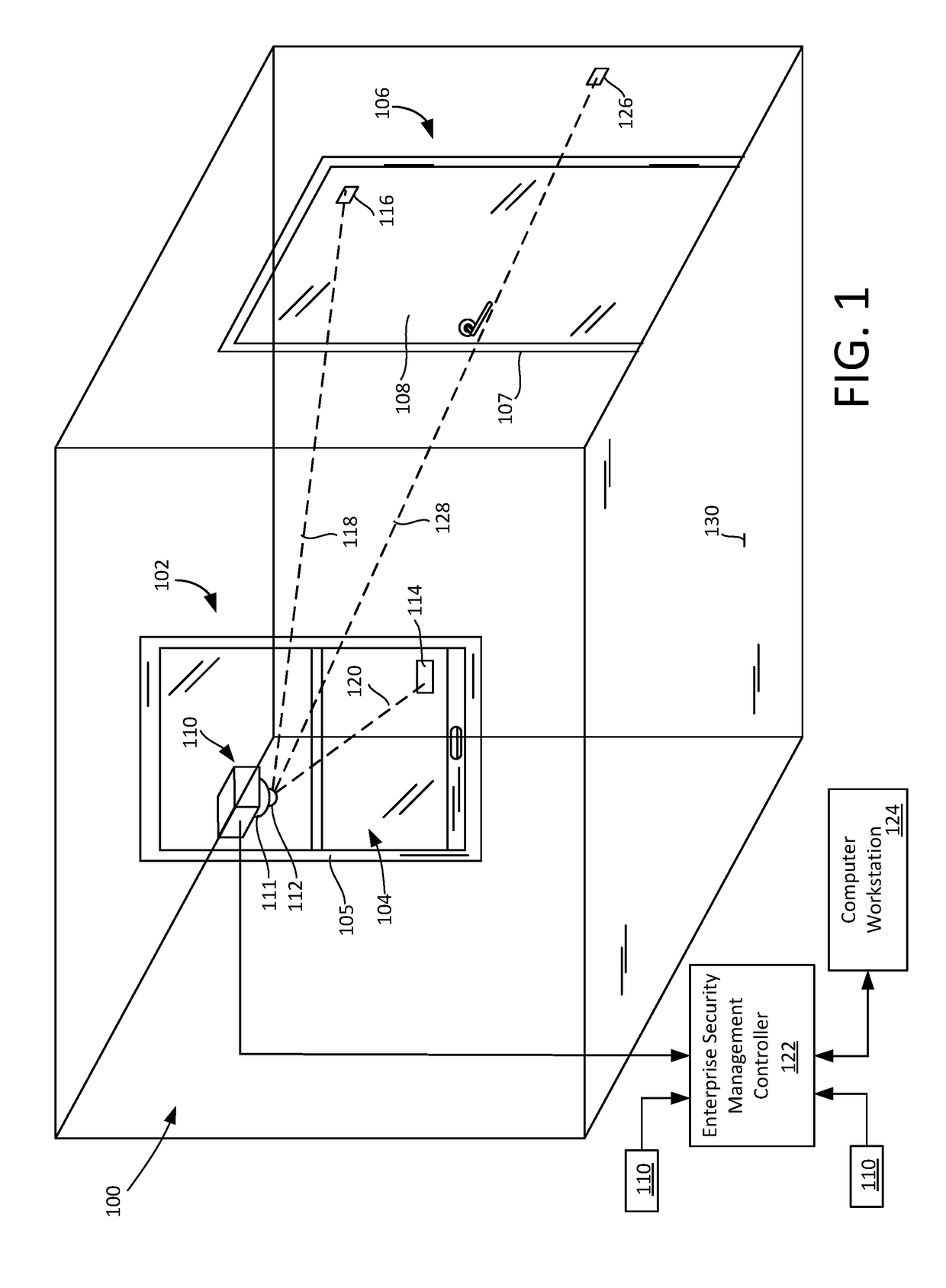

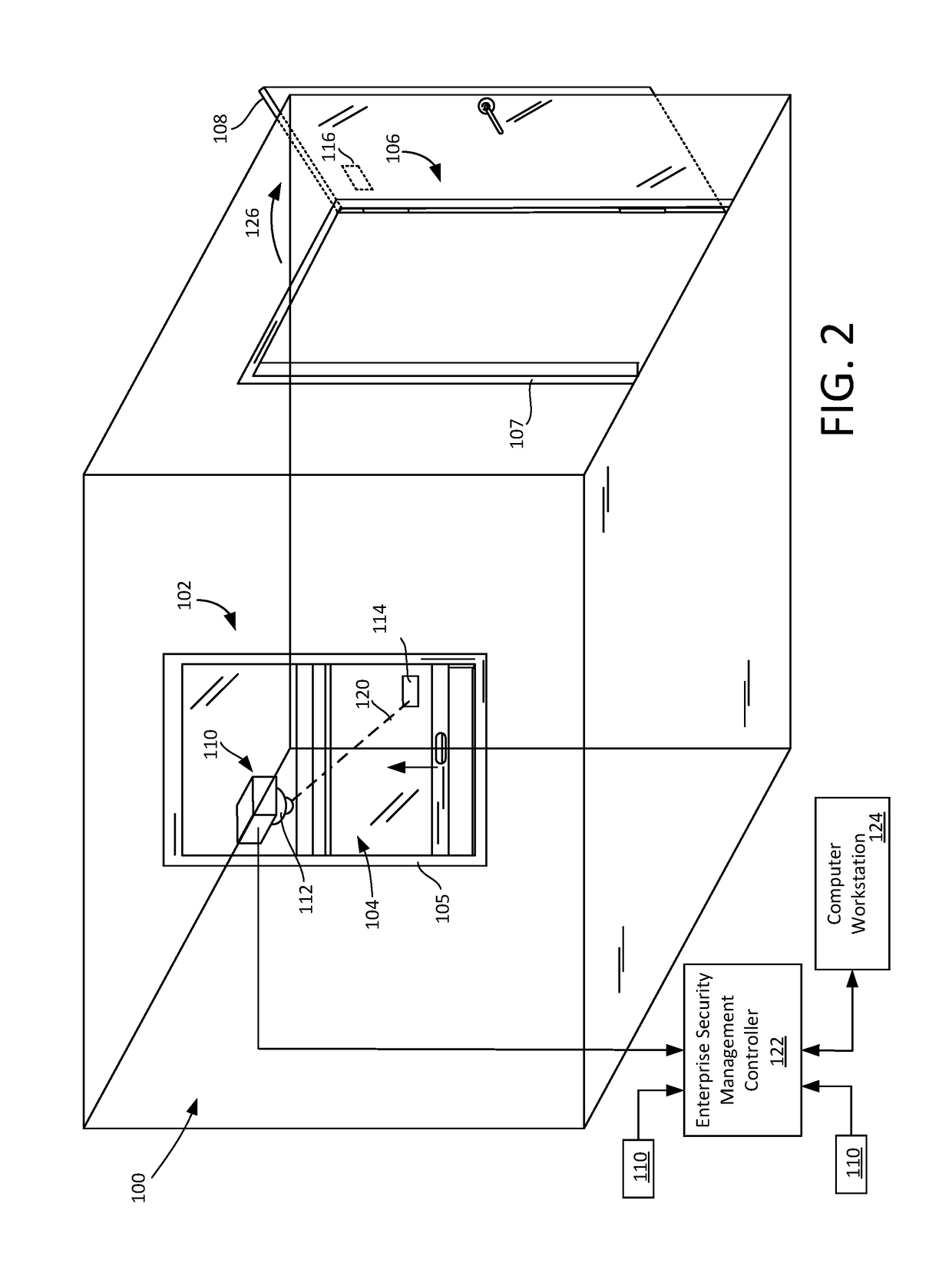

ActiveUS20170294088A1Optimize networkBurglar alarm by openingEnterprise security managementTransceiver

Optical data transceiver is used to illuminate a secured space with an optical data signal which has been modulated to contain a first data sequence. One or more retroreflected optical data signals are received at the optical data transceiver from reflector elements disposed in the secured space. The retroreflected optical data signals are authenticated and a security event notification is selectively communicated to an enterprise security management controller if a variation occurs in regard to at least one retroreflected optical beam condition. The variation can involve a disruption of the optical beam and / or a displacement of the optical beam.

Owner:SENSORMATIC ELECTRONICS CORP

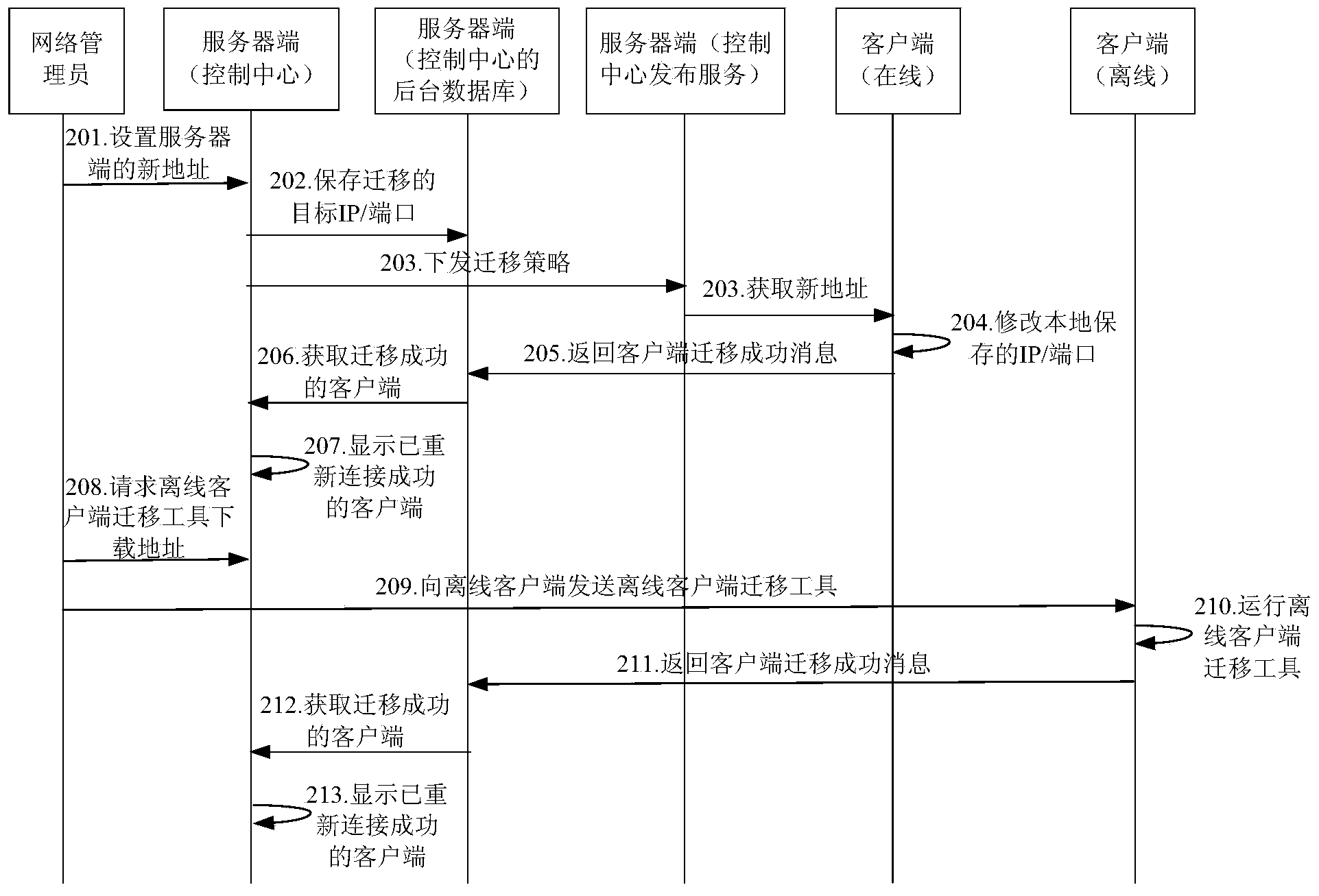

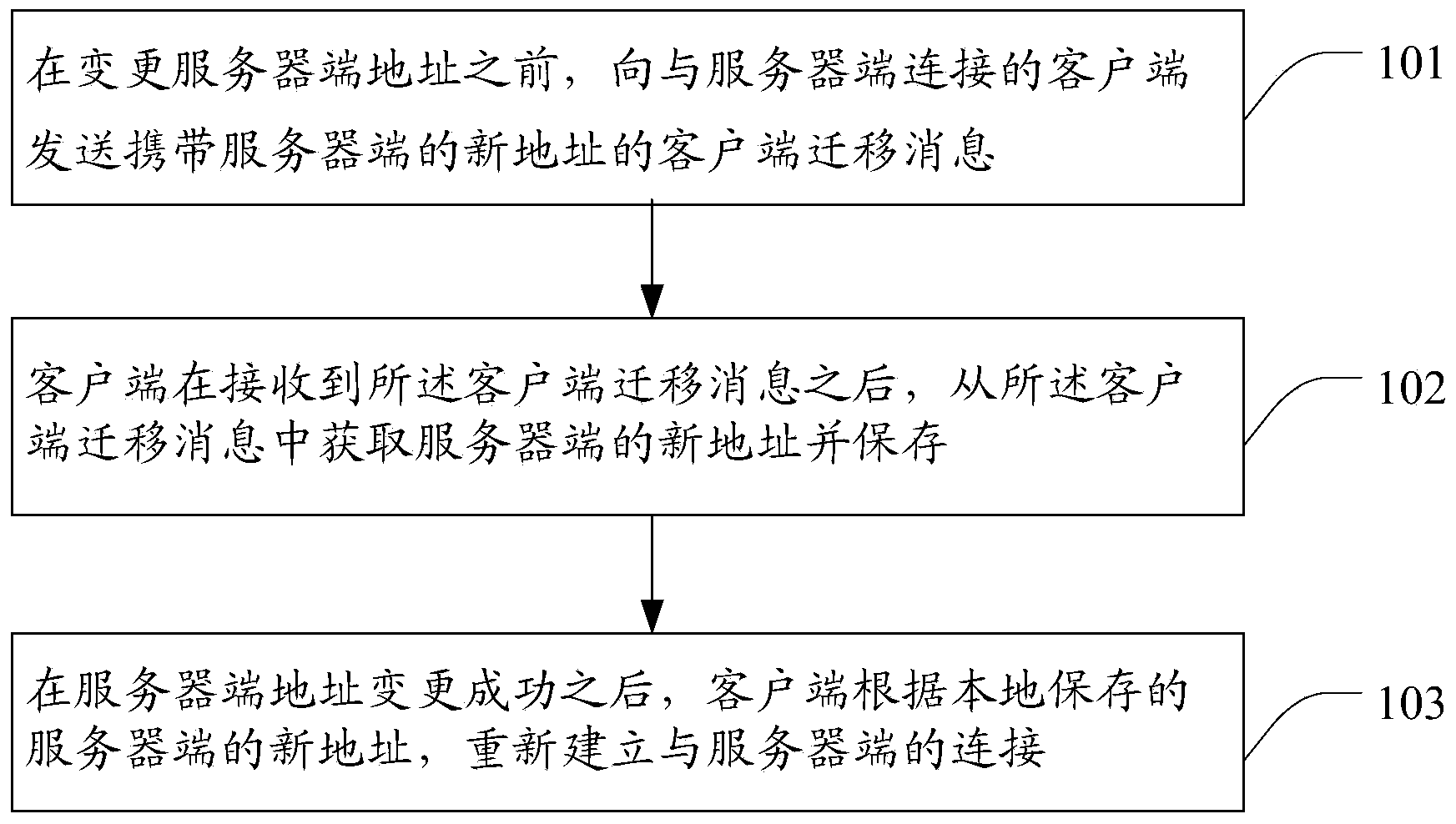

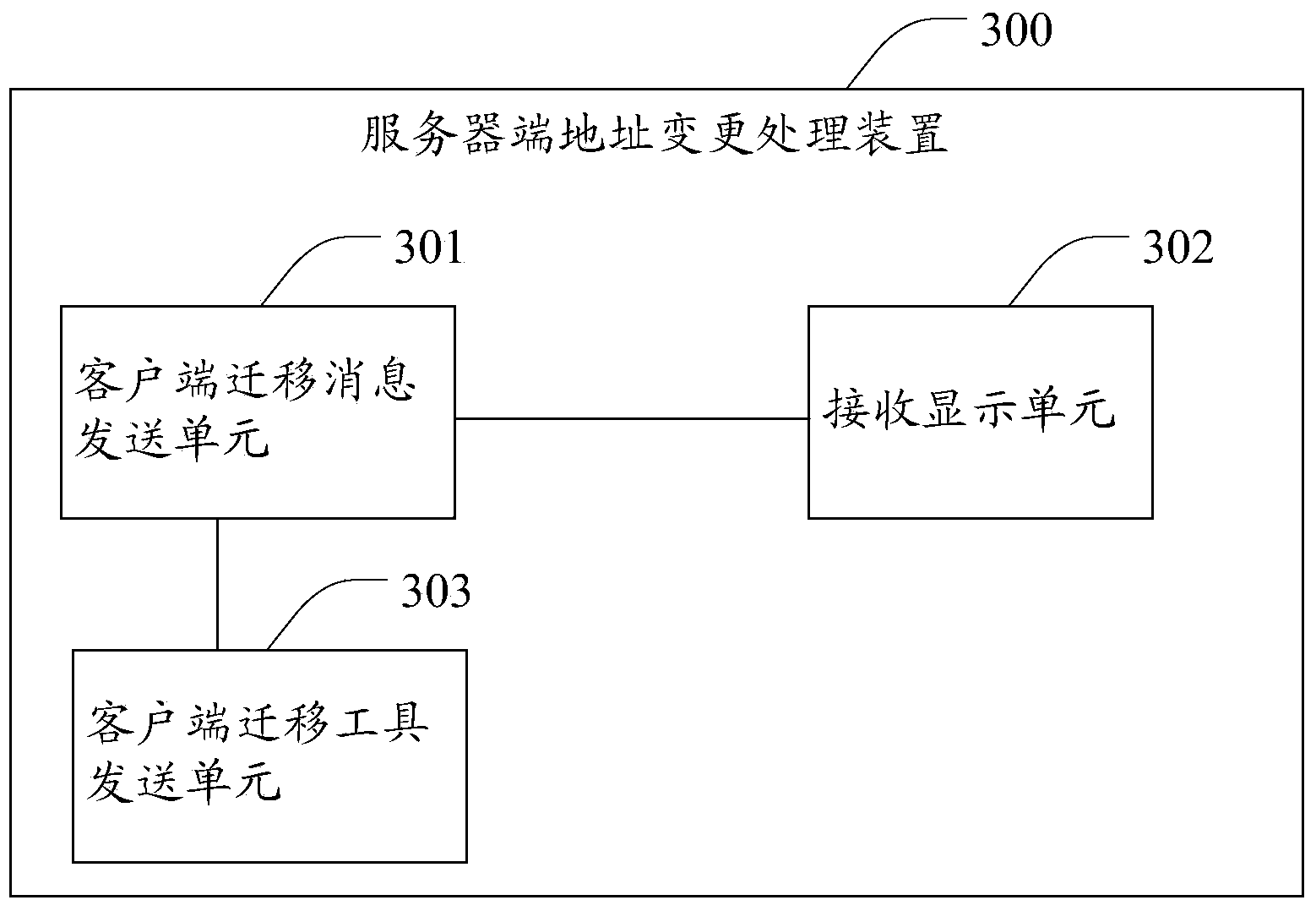

Method, device and system for processing address change of server terminal

InactiveCN103618808ATime-consuming and laborious to solveSolve problems that cannot be manually operated by humansTransmissionEnterprise security managementIp address

The invention relates to the technical field of network communications, and discloses a method, device and system for processing address change of a server terminal. The method comprises the steps of before the address of the server terminal is changed, sending a client terminal transferring message with the new address of the server terminal to a client terminal connected with the server terminal, so that after the client terminal receives the client terminal transferring message, obtaining the new address of the server terminal by the client terminal from the client terminal transferring message and storing the new address, and after the address change of the server terminal succeeds, rebuilding the connection between the client terminal and the server terminal by the client terminal according to the local-storage new address of the server terminal. According to the technical scheme, the problem that existing enterprise safety management software can not achieve the aim of informing the client terminal of conducting transferring after the IP address of the server terminal is changed so as to ensure the client terminal to be online and receiving the control central management is solved.

Owner:BEIJING QIANXIN TECH

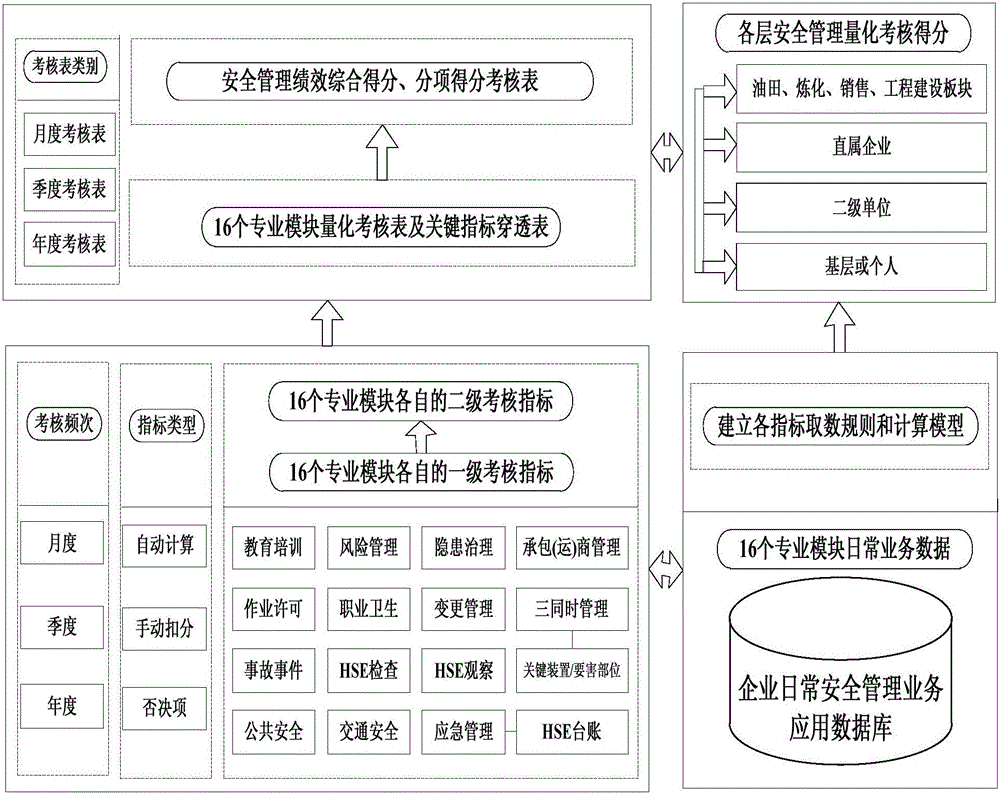

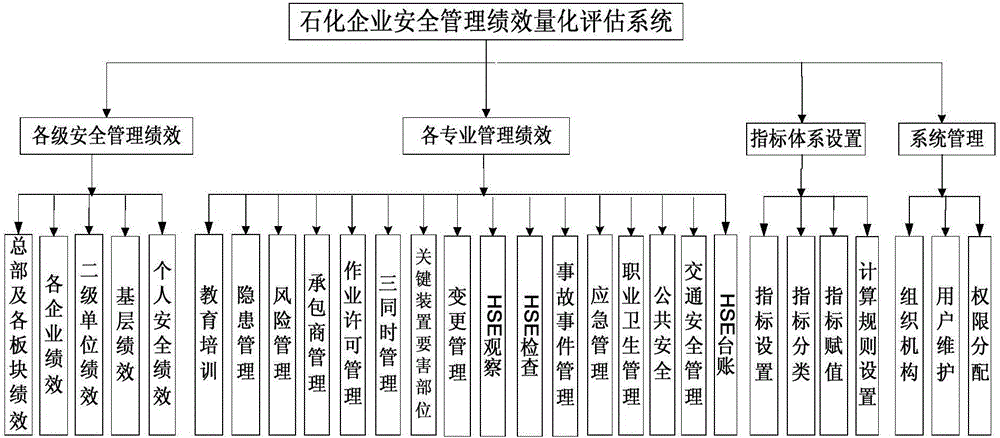

Safety management performance quantification assessment system and method for petrochemical enterprise

InactiveCN105930960ASatisfy securityMeet needsResourcesEnterprise security managementChange management

The invention relates to a safety management performance quantification assessment system and method for a petrochemical enterprise. The method comprises the steps: assessment index system setting and the setting of safety management performance of the headquarter and each part, safety management performance of each enterprise, safety management performance of each secondary unit, safety management performance of each basic unit, personal safety performance and management performance of each specialty. The system employs the daily service data of the professional modules in the safety management information systems of the Sinopec headquarter and each enterprise, such as educational training, risk management, hidden danger management, construction project simultaneous management, key device critical part, operation permission management, contractor management, change management, occupational health management, HSE observation, HSE check, accident management, emergency management, public safety, traffic safety and HSE standing book. Through combining the above safety management performance assessment indexes, classification, scoring and calculation rules, the system achieves the automatic calculation of safety management performance of each level through the information technology. The system is convenient to operate, is stable in operation, is high in efficiency, and is low in cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

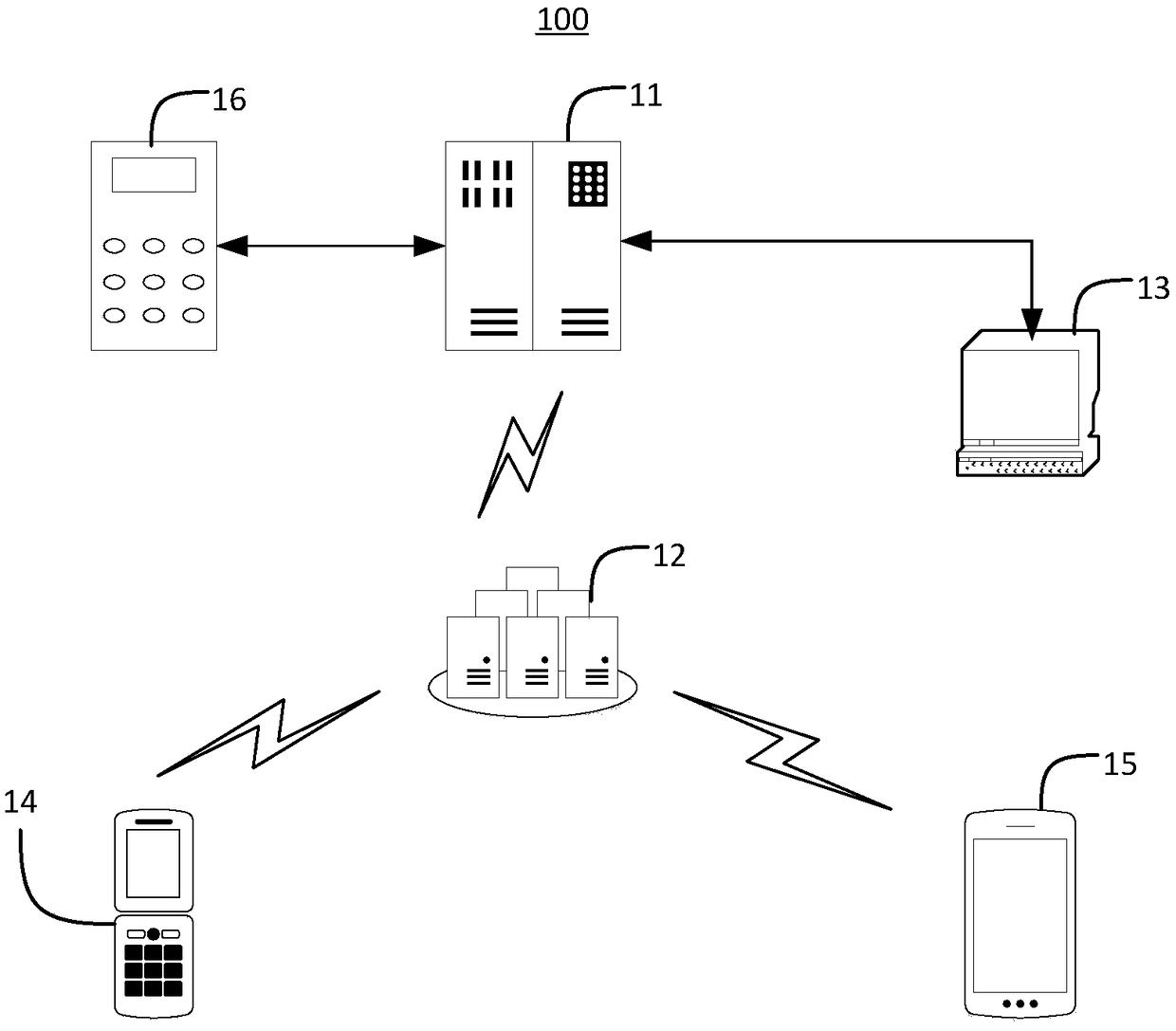

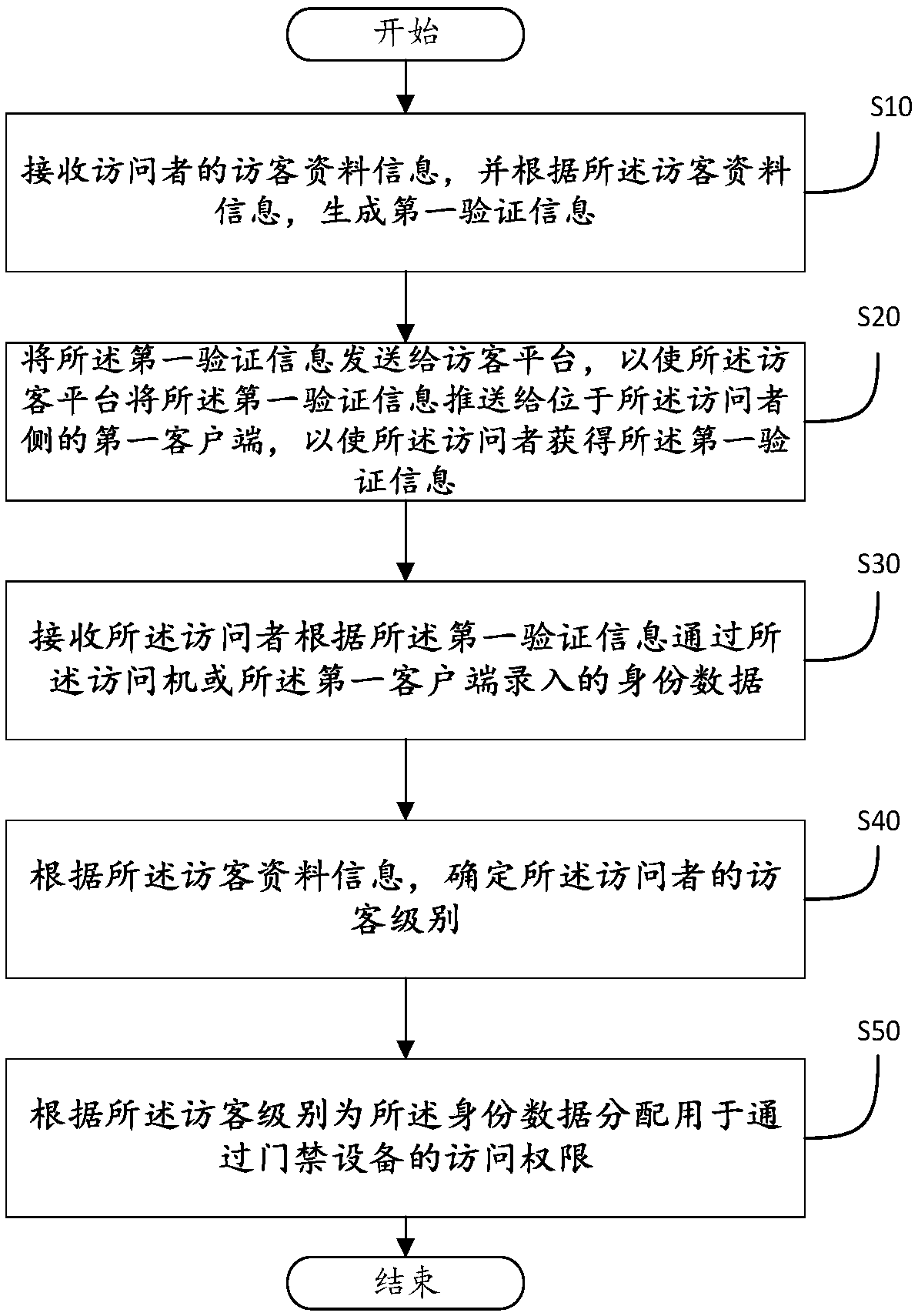

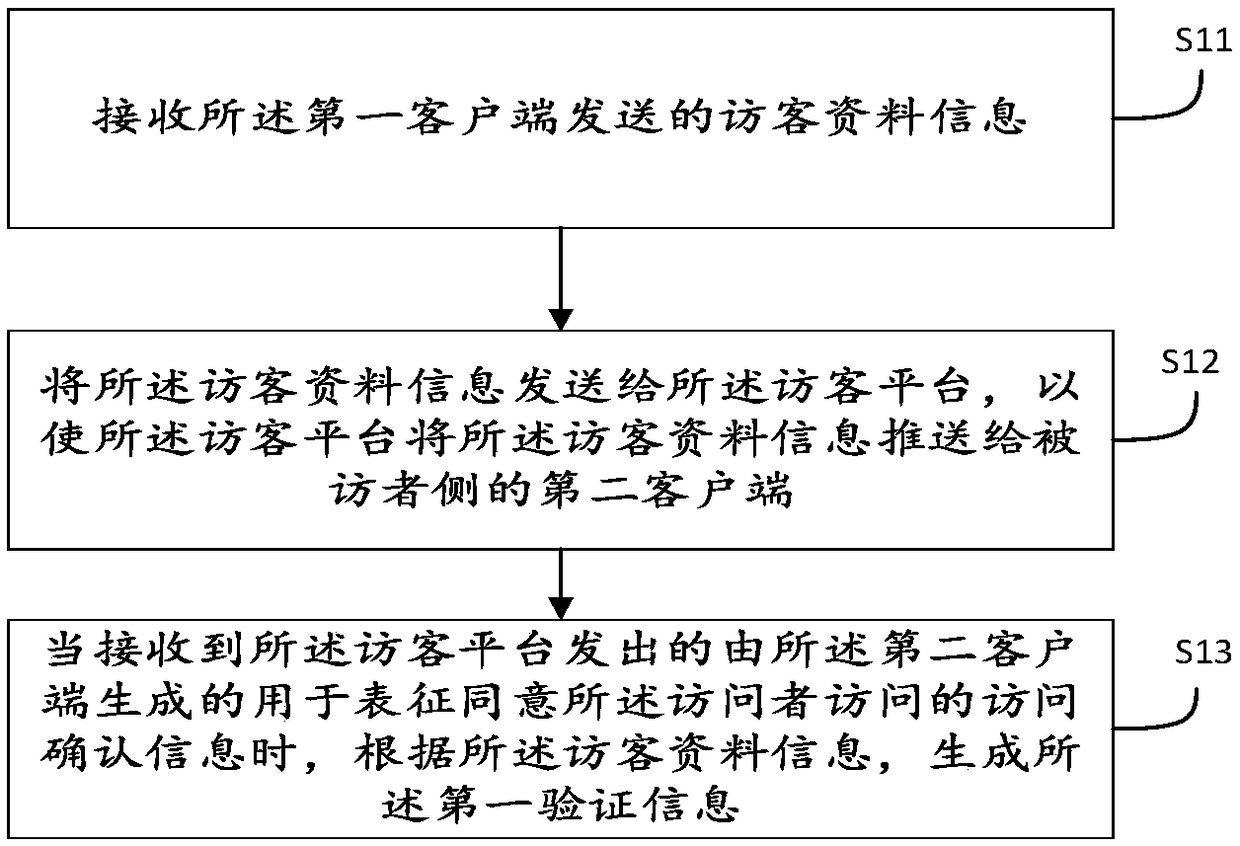

Guest information online management method, device and system

InactiveCN109242424APrevent fraudulent useGuaranteed one-to-one correspondenceOffice automationIndividual entry/exit registersEnterprise security managementOperating system

The invention provides a guest information online management method, device and system. The method is applied to a local guest host computer, including sending the first authentication information toa visitor platform so that the visitor platform pushes the first authentication information to a first client at the visitor side so that the visitor obtains the first authentication information; Receiving identity data inputted by the visitor through the accessor or the first client according to the first authentication information; Determining a visitor level of the visitor according to the visitor profile information; assigning access rights to the identity data for passing through the access device according to the guest level. The access level of the visitor is determined and assignd withdifferent access rights to distinguish and manage the visitor of different levels, and simultaneously the safety management level of the enterprise is improved.

Owner:QIANLIN HENGXING BEIJING TECH

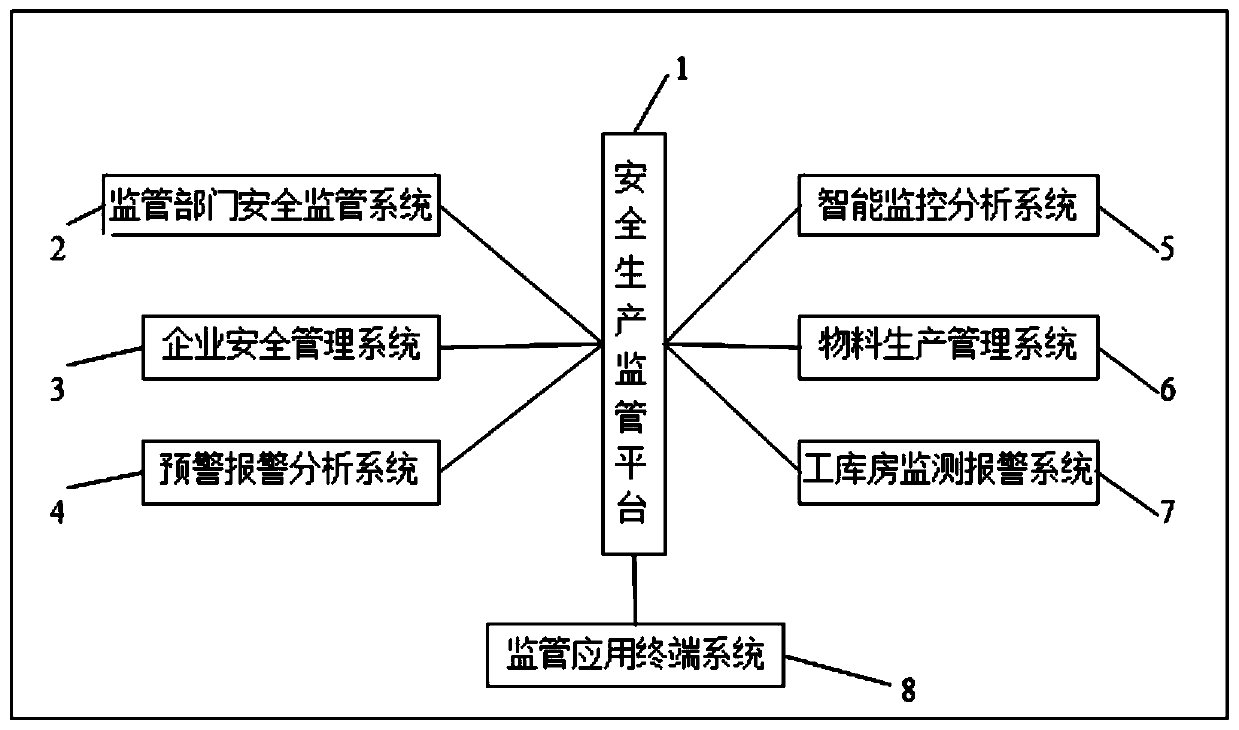

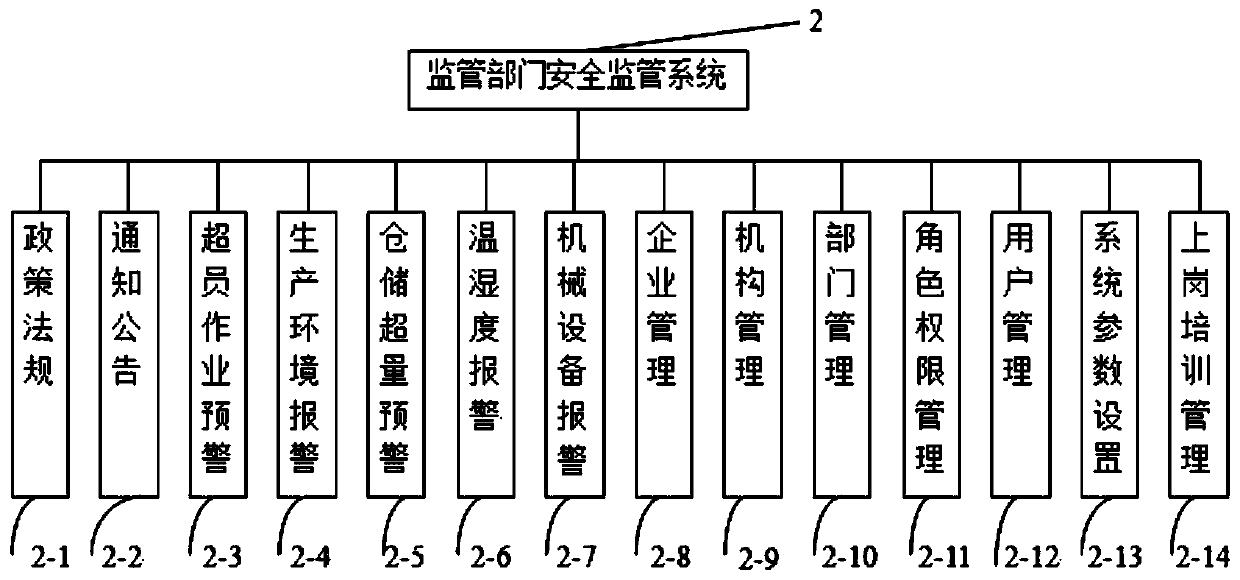

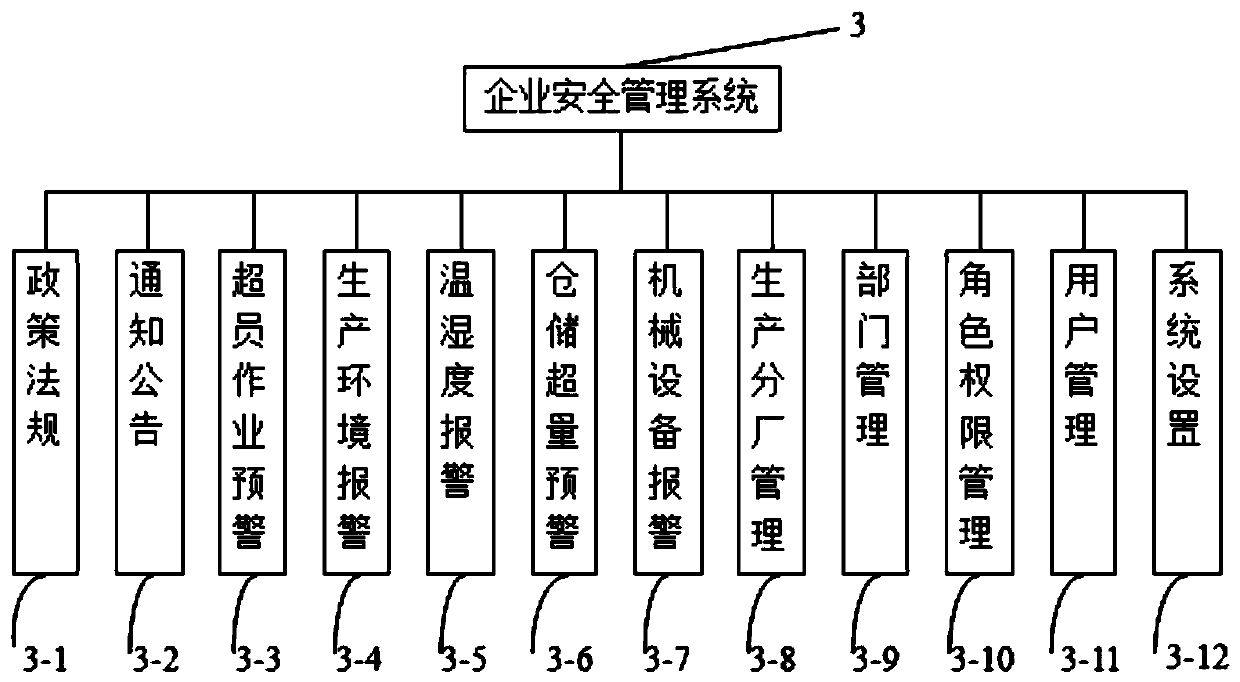

Safety production supervision information system based on artificial intelligence technology

InactiveCN110111440AClarify the main responsibilityChange the thinking of safety managementData processing applicationsRegistering/indicating during manufacturing processEnterprise security managementManagement tool

The invention discloses a safety production supervision information system based on an artificial intelligence technology. The system comprises a supervision department safety supervision system, an enterprise safety management system, an early-warning and alarming analysis system, an intelligent monitoring analysis system, a material production management system, a warehouse monitoring and alarming system, a supervision application terminal system and a safety production supervision platform, wherein the supervision department safety supervision system, the enterprise safety management system, the early-warning and alarming analysis system, the intelligent monitoring analysis system, the material production management system, the warehouse monitoring and alarming system and the supervision application terminal system are connected with the safety production supervision platform respectively through the Internet. Through the whole production supervision information system, a timely, accurate and effective safety production supervision mechanism is established, the three functions of accident prevention, legal supervision and networking monitoring are achieved emphatically, and an effective management tool and a practicable management method are provided for a supervision department.

Owner:常州市瑞德信息科技有限公司

Security sensing method and apparatus

Owner:SENSORMATIC ELECTRONICS CORP

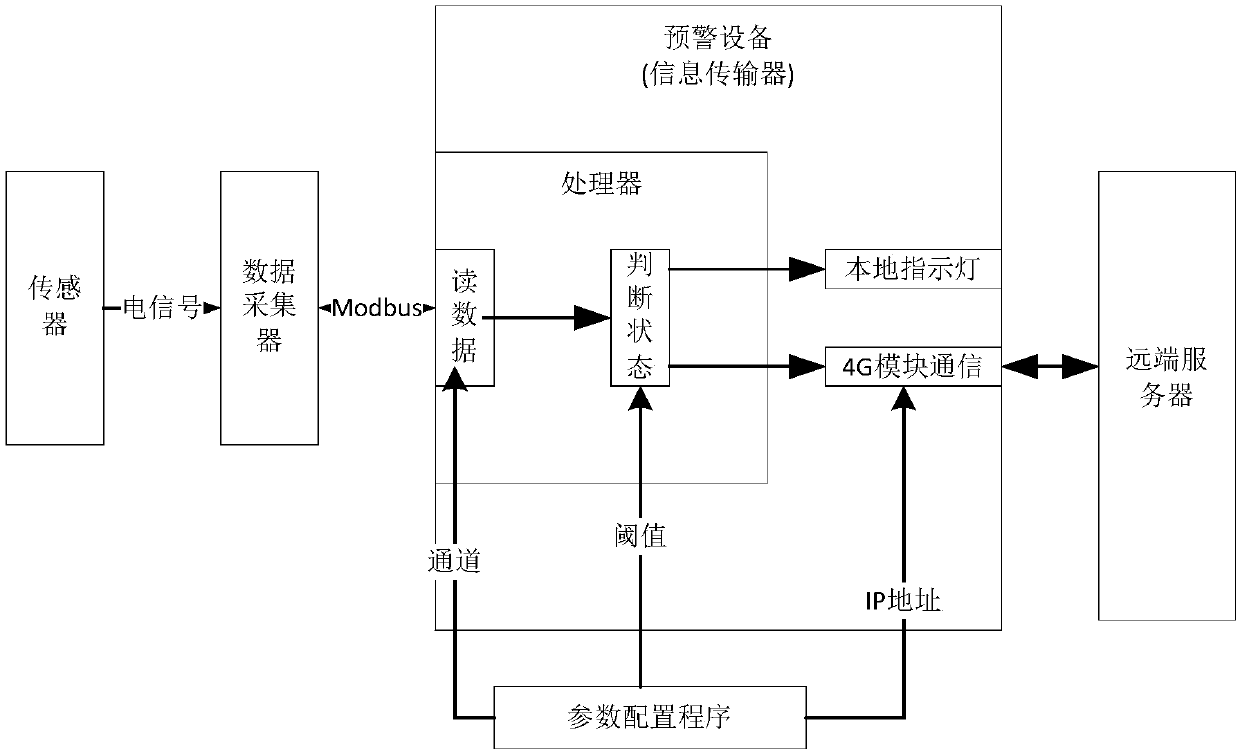

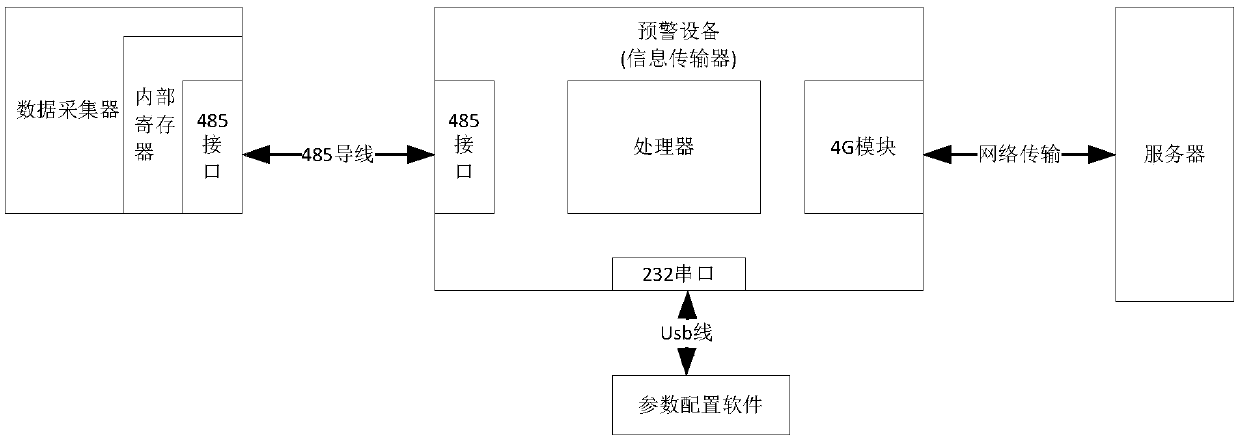

On-line monitoring and early warning system for dangerous chemical major hazard sources

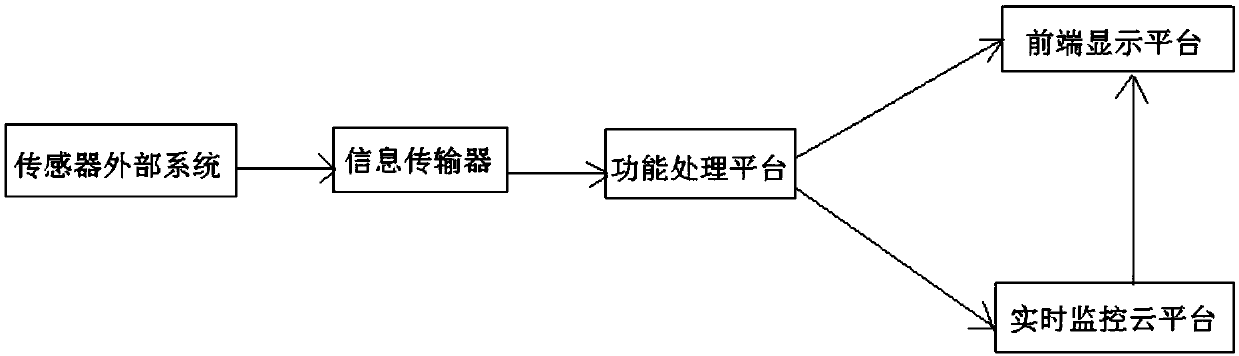

InactiveCN109637076ARealize real-time monitoringRealize dynamic supervisionAlarmsTransmissionEarly warning systemEnterprise security management

The invention discloses an on-line monitoring and early warning system for dangerous chemical major hazard sources. The system comprises a sensor external system, an information transmitter, a function processing platform, a real-time monitoring cloud platform and a display platform; the sensor external system is connected to the information transmitter through an RS485, and the sensor external system and the information transmitter are mutually in communication through a communication protocol in a master-slave mode; the information transmitter reads data in a register to carry out calculation to obtain a final required judgment object, the final required judgment object is compared with a limit range corresponding to the material specified in the production specification in a safe production environment, then a normal or abnormal alarm signal is output, and the signal is transmitted to the function processing platform; and the function processing platform processes the data accordingto the type of the received signal, and transmits the data to the real-time monitoring video cloud platform and the front-end display platform. According to the system, the real-time state of the dangerous chemicals and the major hazard source can be transmitted to a supervision department and an enterprise security management department, and therefore real-time monitoring and dynamic supervisionare realized.

Owner:无锡市安泰安全技术服务有限公司

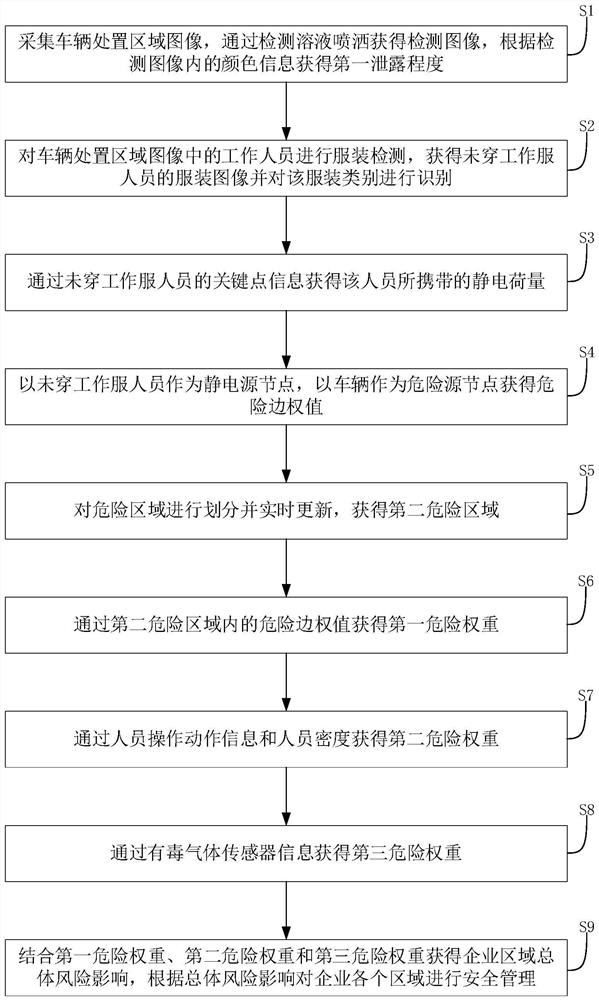

Hazardous chemical enterprise five-in-one safety management method based on artificial intelligence and Internet of Things

PendingCN113052070AReasonable warningReasonable responseImage analysisOffice automationToxic gasEnterprise security management

The invention relates to the field of chemical enterprise safety management, in particular to a hazardous chemical enterprise five-in-one safety management method based on artificial intelligence and the Internet of Things. The method comprises the steps of collecting a vehicle disposal area image, obtaining a detection image through detection solution spraying, and obtaining a first leakage degree; obtaining a clothing material of a person who does not wear the work clothes; obtaining the electrostatic charge quantity carried by the personnel; calculating a danger edge weight and constructing a danger distribution map; dividing the dangerous area by the dangerous source node and updating to obtain a second dangerous area; obtaining a first danger weight through the danger edge weight in the second danger area; obtaining a second danger weight through the personnel operation action information and the personnel density; obtaining a third danger weight through poisonous gas sensor information; and performing safety management on each area of the enterprise in combination with the first danger weight, the second danger weight and the third danger weight. According to the invention, real-time and effective security management is carried out on the interior of the enterprise through the weights of the plurality of regions.

Owner:河南鑫安利安全科技股份有限公司

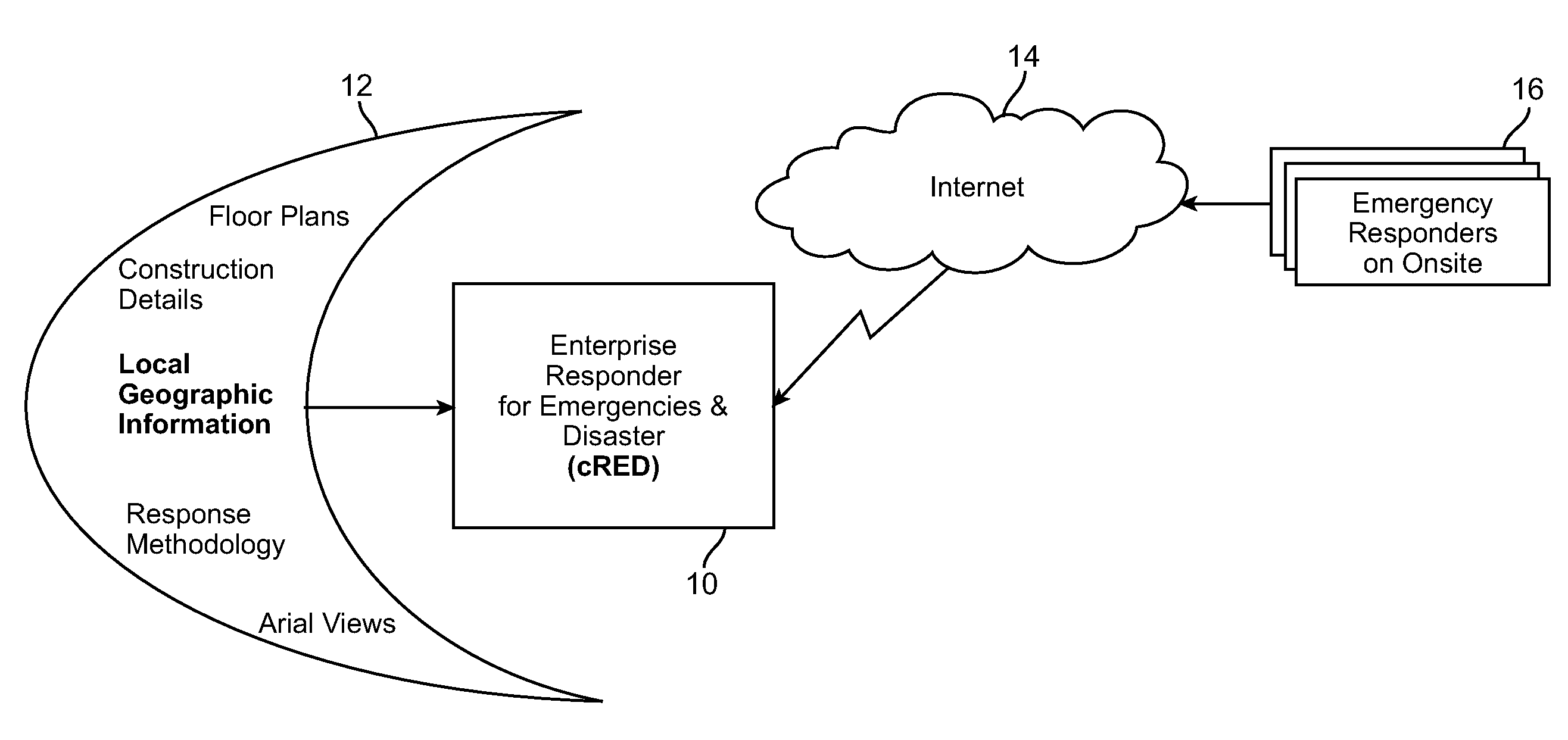

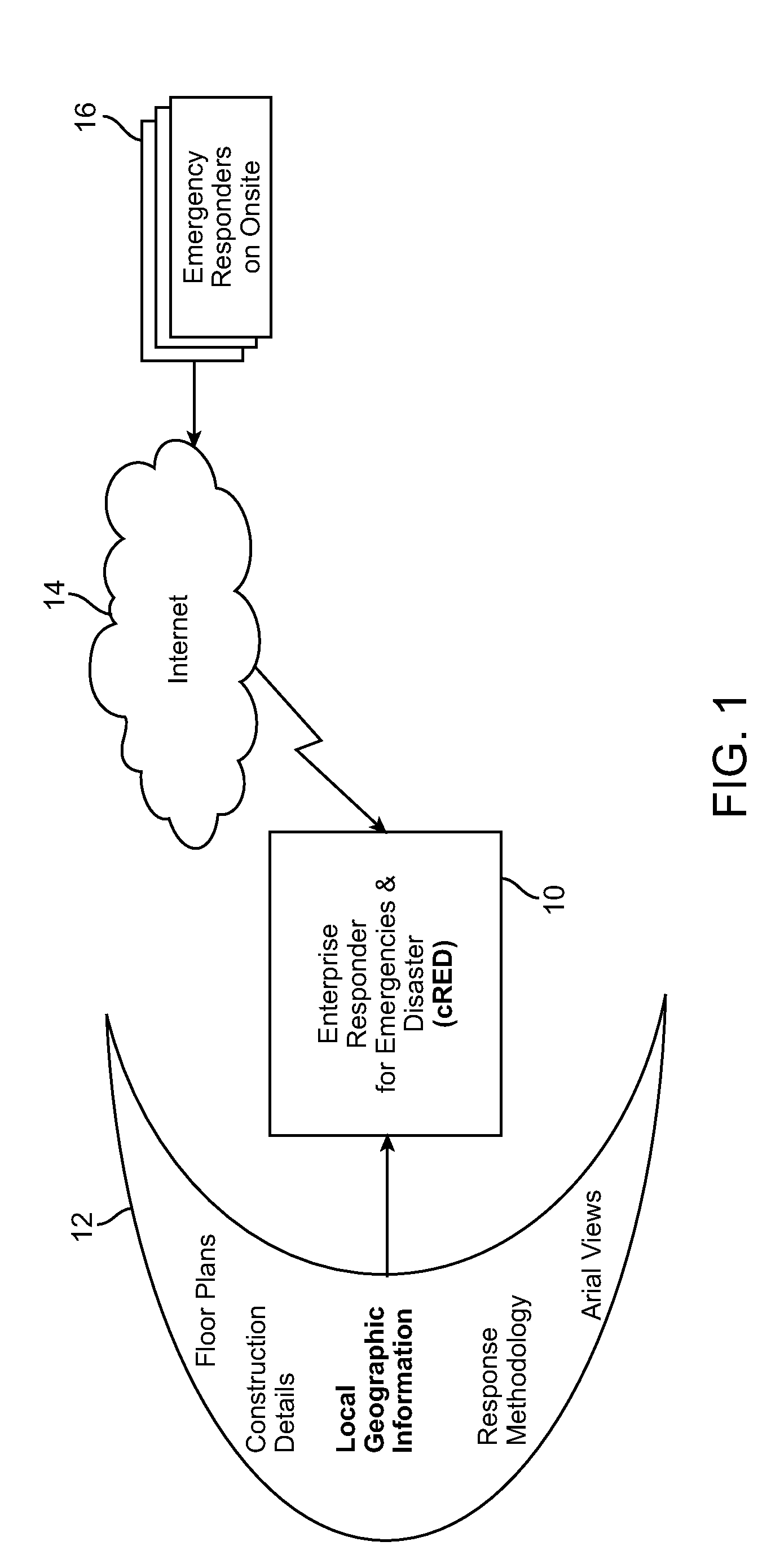

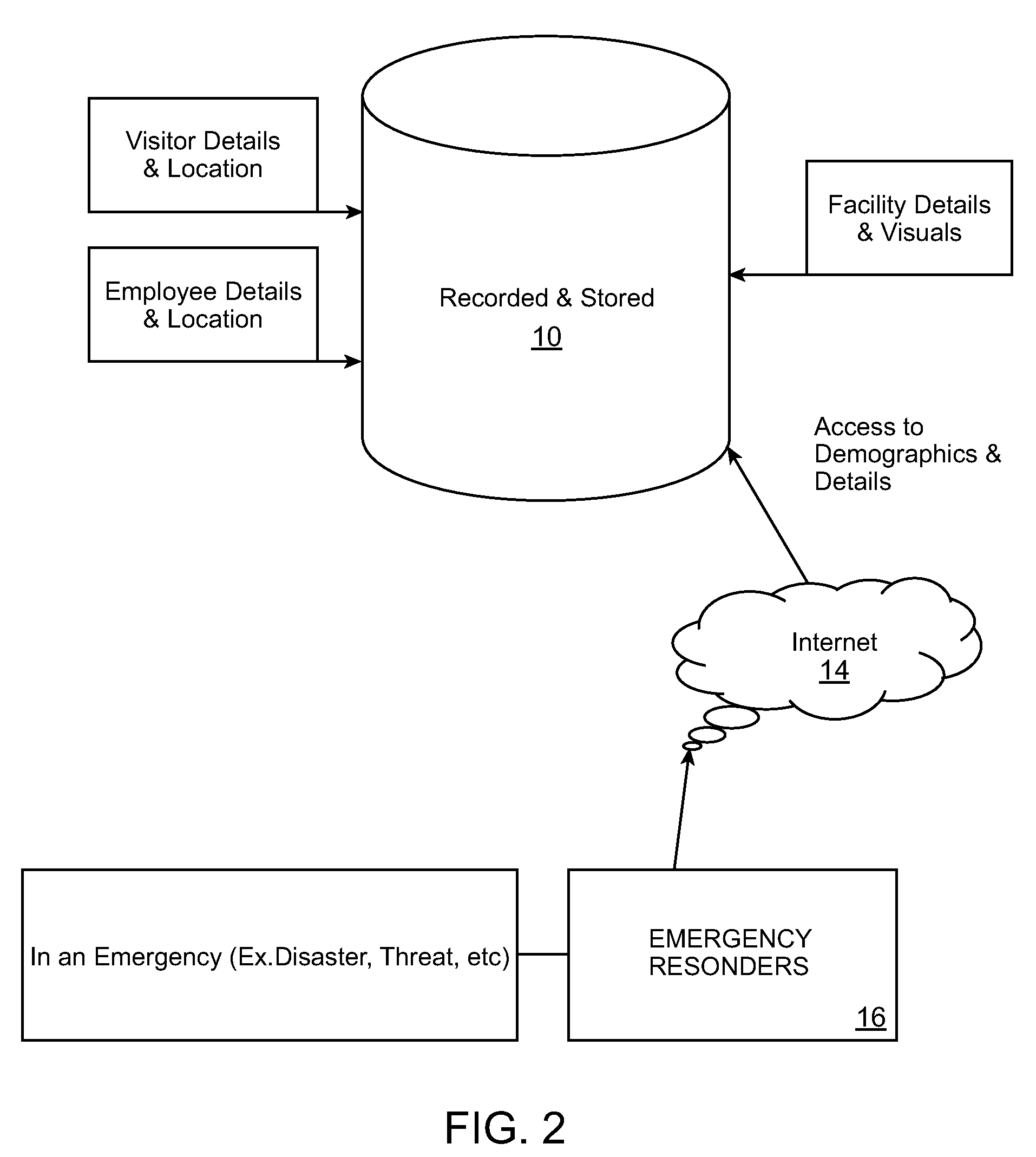

Enterprise responder for emergencies and disaster

InactiveUS7577989B1Digital data processing detailsUnauthorized memory use protectionEnterprise security managementComputer science

A enterprise security management (ESM) system having a web-based platform for authorizing and monitoring visitors of a secure facility and for further providing a time-stamping process for noting the time of arrival and departure of the visitors and for alerting authorities when the duration of stay of a visitor has exceeded the predetermined time for visiting allotted the visitor.

Owner:UNITED SOFTWARE ASSOCS

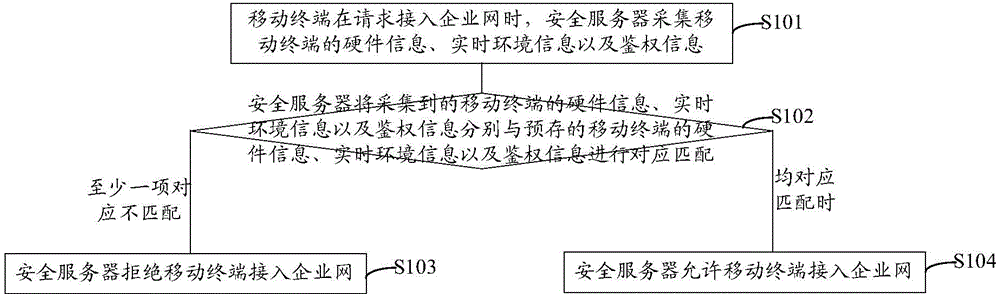

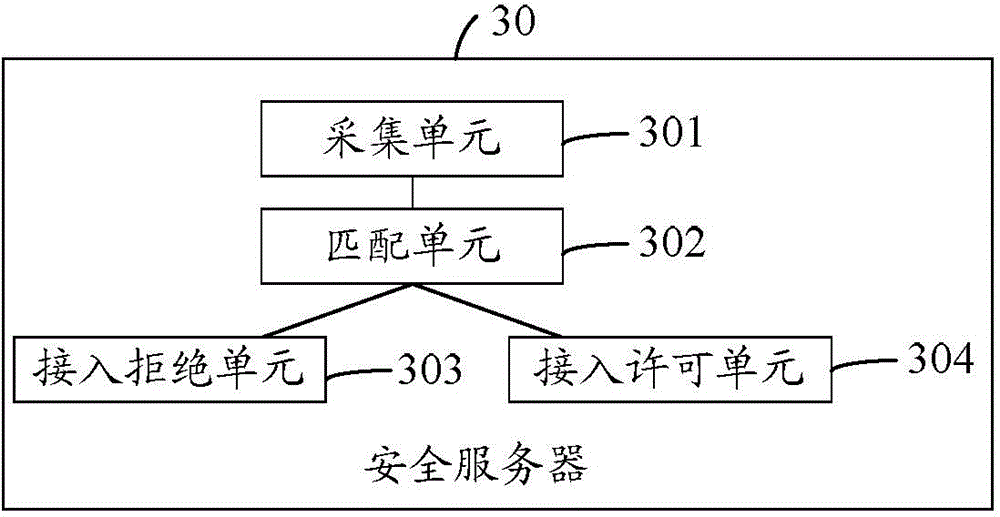

Enterprise safety management method, equipment and system

ActiveCN105992206AComprehensive security controlReduce security risksSecurity arrangementEnterprise security managementComputer science

The embodiment of the invention discloses an enterprise safety management method, equipment and system. The enterprise safety management method comprises the steps: when a mobile terminal requests to access an enterprise network, acquiring the hardware information, the real time environment information and the authentication information of the mobile terminal by means of a safety server; correspondingly matching the acquired hardware information, real time environment information and authentication information of the mobile terminal with the pre-stored hardware information, real time environment information and authentication information of the mobile terminal; when at least one item of the hardware information, real time environment information and authentication information, acquired by the safety server, of the mobile terminal is not matched with the pre-stored hardware information, real time environment information and authentication information of the mobile terminal, rejecting the mobile terminal to access the enterprise network; when all the hardware information, real time environment information and authentication information, acquired by the safety server, of the mobile terminal are matched with the pre-stored hardware information, real time environment information and authentication information of the mobile terminal, allowing the mobile terminal to access the enterprise network.

Owner:XIANGYANG BRANCH CHINA MOBILE GRP HUBEI CO LTD

WeChat platform based on-site security risk management and control method

PendingCN106339828AImprove efficiencyImprove the level ofResourcesEnterprise security managementControl system

The invention discloses a WeChat platform based on-site security risk management and control method, wherein an onsite security risk management and control system is established on the WeChat platform. On-site staffs register information on the work content, work place, and work team members into the system before they start high-risk work. The onsite security risk management and control system delivers such work through the Wechat platform to the Wechat accounts of the management staffs at all levels of an enterprise so that the management staffs at all levels could receive the work progress at the onsite risky work and conduct real time monitoring as well as instant interventions through smart phone installed Wechat. With the invention, every management staff in an enterprise can have first hand information about onsite security. At any time or any place, the management staffs can receive first hand information about various types of onsite risky work and conduct monitoring so that real time management over the security risk work can be performed and the management efficiency and level are greatly improved.

Owner:胡晓光

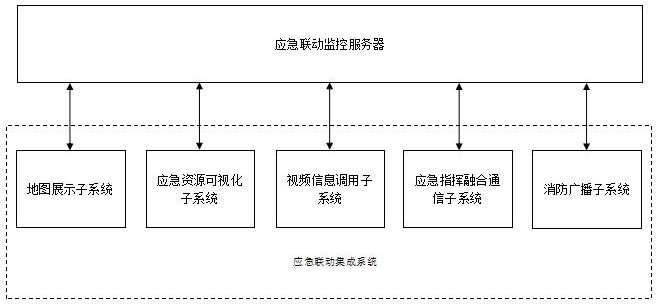

Industrial safety production emergency linkage system

PendingCN111638694AImprove securityStrengthen security managementProgramme total factory controlEnterprise security managementIndustrial area

The invention discloses an industrial safety production emergency linkage system. The emergency linkage system comprises an emergency linkage integrated system and an emergency linkage monitoring server, wherein the emergency linkage integrated system comprises an alarm position map display subsystem, an emergency resource visualization subsystem, a video information calling subsystem, an emergency command fusion communication subsystem and a fire-fighting broadcast subsystem. By monitoring alarm points in real time, the video information and the position information are called to discover accident sites in time, so management of dangerous sources and key equipment of chemical enterprises is enhanced, and scientificity of enterprise safety management is improved; meanwhile, remote real-time fire-fighting resource monitoring can be realized through emergency resource visualization, emergency command fusion communication and fire-fighting broadcasting, when major accidents happen, emergency rescue can be assisted, the safety guarantee capacity of industrial production is promoted, a management and technical level of enterprise safety production work is improved, and the system has very important significance in protecting the life and property safety of people in the country and industrial areas.

Owner:CHENGDU GREATECH ELECTRICS

Statistics positioning system for high-place operation of refinery enterprise

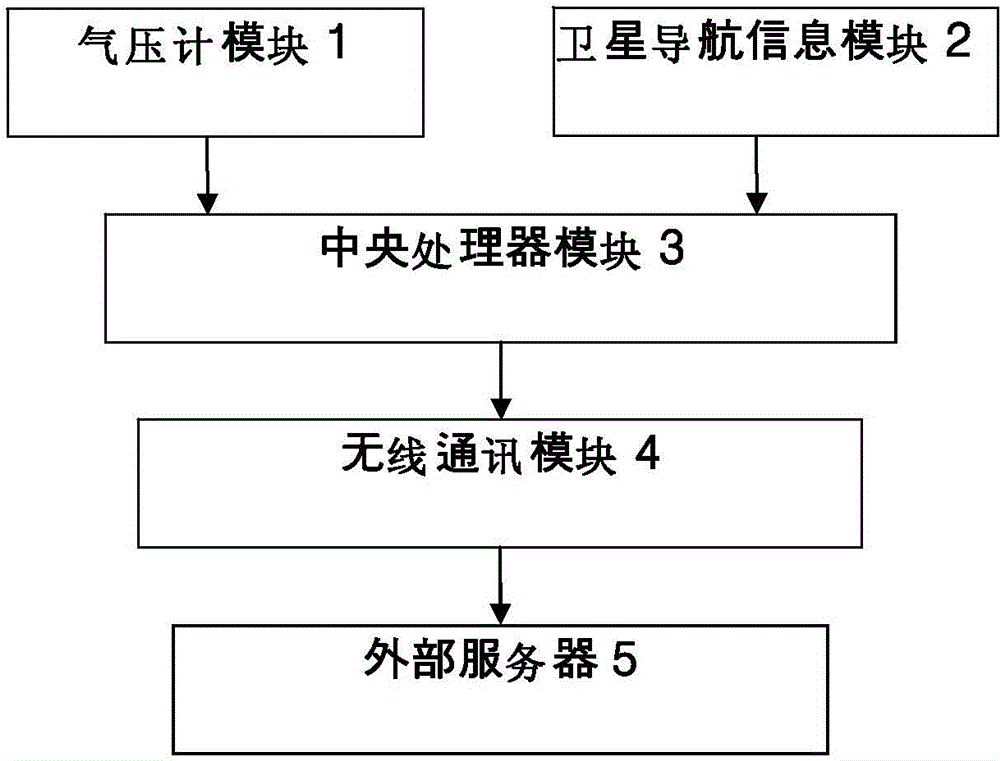

InactiveCN104808234AImprove management levelReduce falling from heightsHeight/levelling measurementSatellite radio beaconingEnterprise security managementSocial benefits

The invention discloses a statistics positioning system for high-place operation of a refinery enterprise. The statistics positioning system comprises an air pressure gauge module, a satellite navigation information module, a wireless communication module, a central processing module and an external server. According to the statistics positioning system, a brand-new design is performed on the original high-place operation safety belt, thus, a safety administrator of the refinery enterprise can perform statistics on the number of field high-place operation personnel, and compare the number of the field high-place operation personnel with issued operation allowable number; if a rule-breaking operator is discovered, coordinates of the rule-breaking operator are positioned, therefore the falling accident caused by rule-breaking operation is reduced, and the HSE (health and safety executive) management level of engineering construction is improved; the statistics positioning system has a broad application prospect, and greater social benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

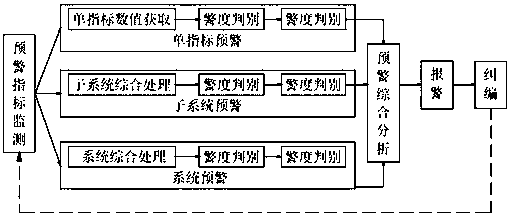

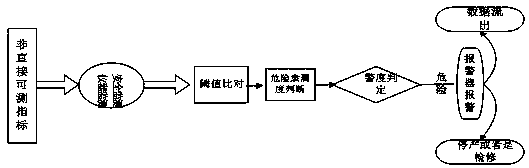

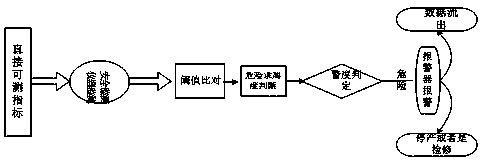

Method for constructing safety early warning system

The invention discloses a method for constructing a safety early warning system, which comprises the steps of early warning index monitoring, early warning, early warning comprehensive analysis, alarming and deviation correcting, and is characterized in that early warning comprises single-index early warning, subsystem early warning and system early warning. The deviation correcting step is connected with the early warning index monitoring step to perform data feedback adjustment. The safety early warning system disclosed by the invention can acquire safety early warning degree information ofthe whole chemical industry production system, achieves an effect of understanding and mastering system safety conditions in the production process, can acquire safety early warning for subsystems, and acquires safety early warning for the whole chemical industry production system on the basis of safety early warning for the subsystems. The safety early warning is sent to the enterprise safety management and technical personnel through an internal communication network of an enterprise to serve as a reference for taking corresponding measures and starting a corresponding level of emergency plan. The method performs analysis, evaluation and early warning on the chemical production process, can effectively avoid occurrence of safety accidents in the chemical production process and has very high practicability and operability.

Owner:ZHEJIANG OCEAN UNIV

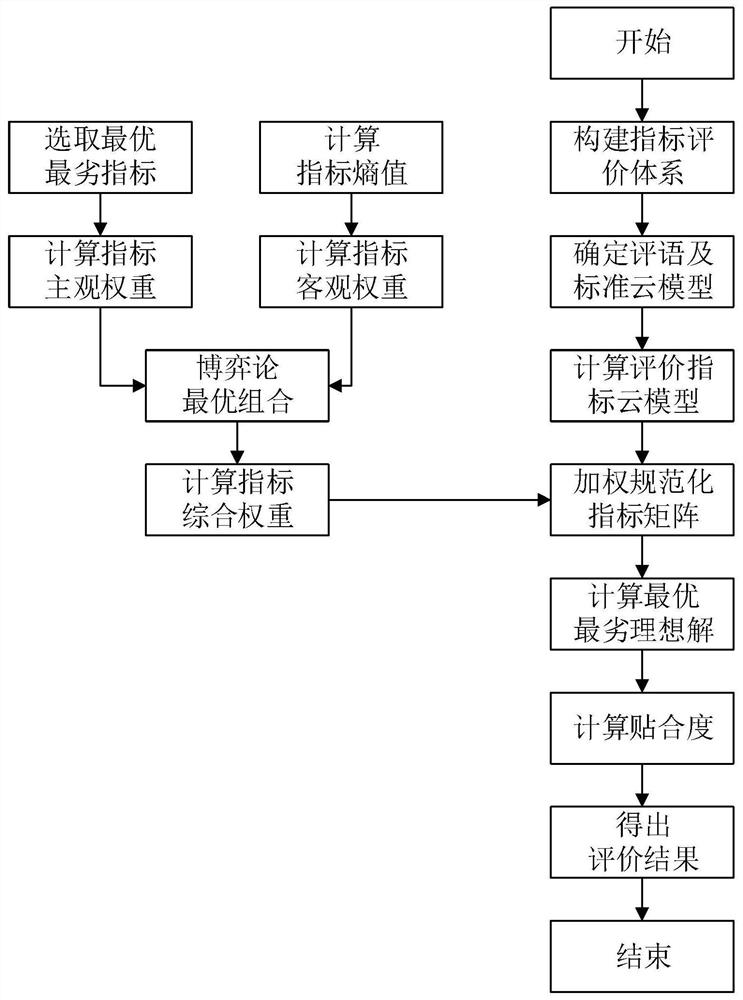

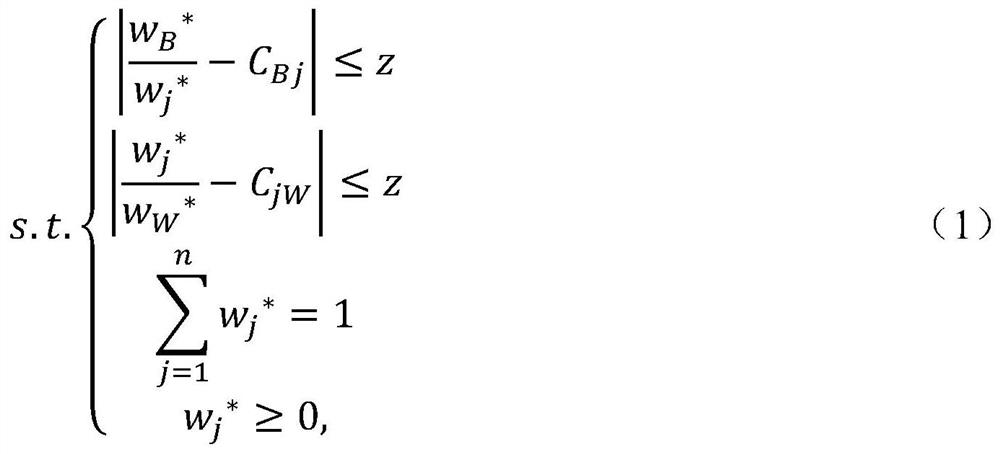

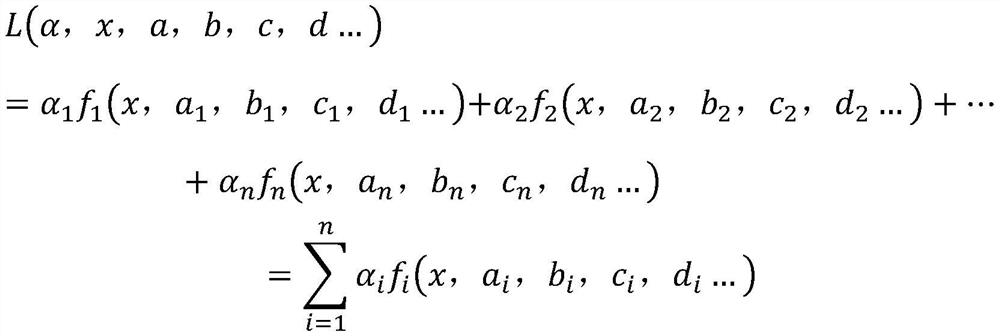

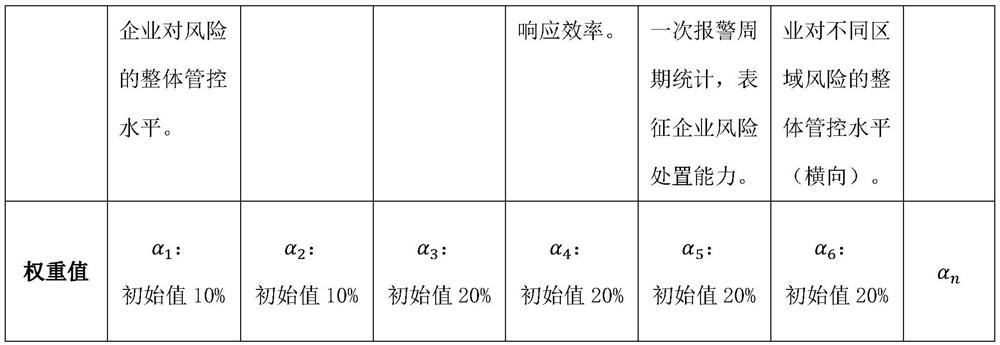

Industry and trade enterprise safety management capability evaluation method based on cloud model

PendingCN113159580AMeet subjective needsForecastingResourcesEnterprise security managementEvaluation result

The invention discloses an industry and trade enterprise safety management capability evaluation method based on a cloud model. The method comprises the following steps: constructing an industry and trade enterprise safety management capability index evaluation system; establishing a comment set and determining a standard cloud model; determining a combined weight of the safety management capability evaluation indexes of the to-be-evaluated industrial and trade enterprises; determining a safety management capability comprehensive cloud model of each to-be-evaluated industry and trade enterprise; and evaluating and sorting the safety management capability of each industry and trade enterprise by using the cloud model. The problem that the evaluation result has deviation due to the fact that a single evaluation method is adopted in an existing industrial and trade enterprise safety management capability evaluation method and subject and guest weight distribution is too subjective is solved. According to the method, the cloud model and the TOPSIS method are combined, a plurality of evaluation objects are sorted, and uncertainty and fuzziness in information are better mined. Meanwhile, the Nash equilibrium is introduced into the calculation of the combined weight based on the game theory thought, so that the objectivity and accuracy of the evaluation result are ensured.

Owner:SOUTH CHINA UNIV OF TECH

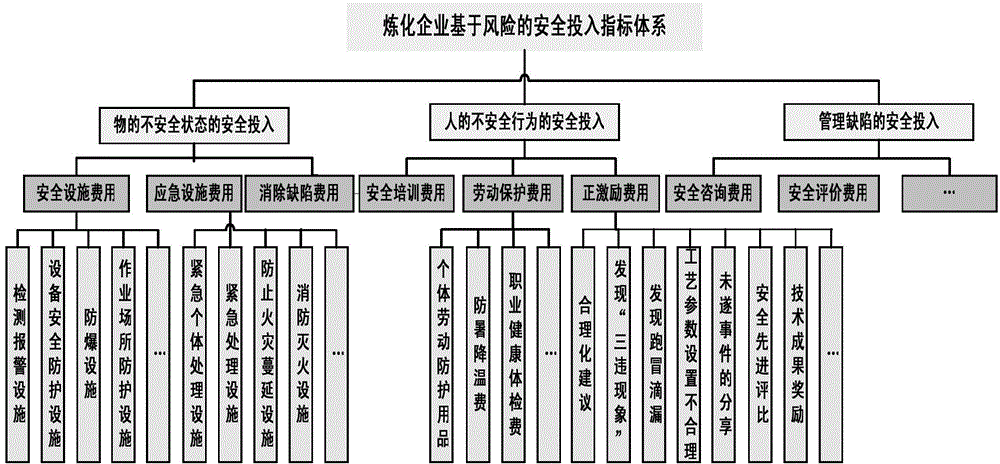

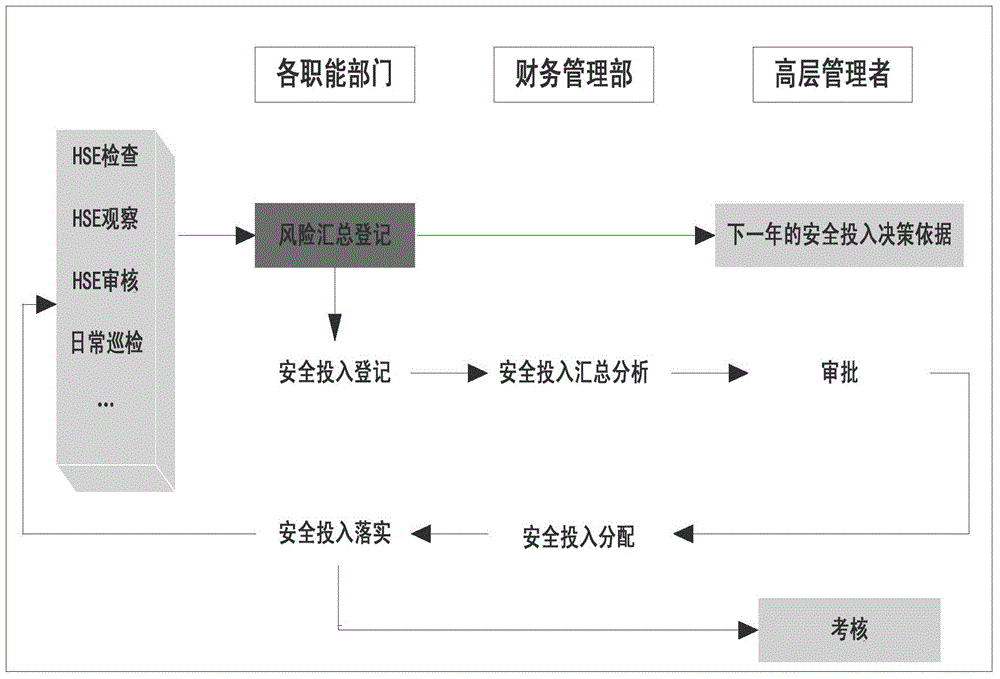

Safety investment assistant decision-making method and system for refinery enterprise based on risk identification

InactiveCN104809598AImprove safety management levelScientific decision-making guidanceResourcesEnterprise security managementDecision maker

The invention provides a safety investment assistant decision-making method for a refinery enterprise based on risk identification, comprising the following steps: step 1, risk registration to realize the registration for different types of risks; step 2, safety investment registration to realize the registration for different types of safety investments of the refinery enterprise; step 3, account generation; step 4, statistical analysis. According to the method and the system disclosed by the invention, the enterprise decision maker can obtain a scientific, intuitive and effective decision-making guidance when the safety investment decision-making is carried out, and has very important realistic significance in determination of a safety investment amount, reasonable distribution of a management resource, playing of efficiency of the safety investment to the largest degree, reduction of costs and increase of benefits, and promotion of safety management level of the refinery enterprise comprehensively.

Owner:CHINA PETROLEUM & CHEM CORP +1

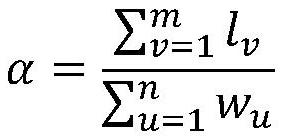

Enterprise safety production risk index analysis system

PendingCN112257985ARealize automatic quantitative evaluationHighlight substantiveAlarmsResourcesEnterprise security managementSafety index

The invention provides an enterprise safety production risk index analysis system. The system comprises a cloud monitoring server, a plurality of mobile terminals, a field alarm device and an alarm information collection device. Each mobile terminal is used for providing a safety management condition evaluation index and an enterprise inherent danger attribute evaluation index; the field alarm device is used for providing alarm parameter information. The alarm information collection device is used for providing key parameter monitoring alarm information; the cloud monitoring server is used forcalculating a safety production risk index of the enterprise according to a safety index algorithm; the algorithm of the safety index comprises the following steps: calculating an enterprise key parameter monitoring alarm index L according to a formula; calculating an enterprise safety management condition index M according to a formula; calculating an enterprise inherent danger attribute index Saccording to a formula enterprise inherent danger attribute; and calculating a safety production risk index T according to a formula T = L * M * S.

Owner:HENAN HANWEI ELECTRONICS

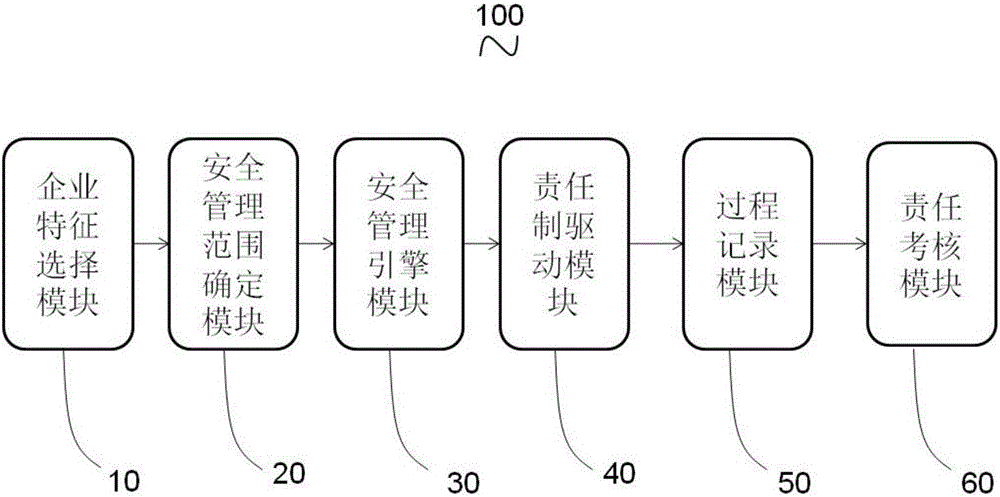

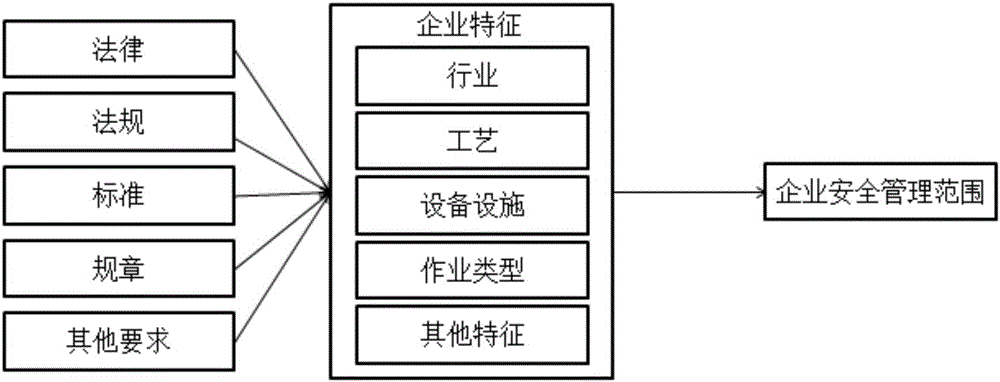

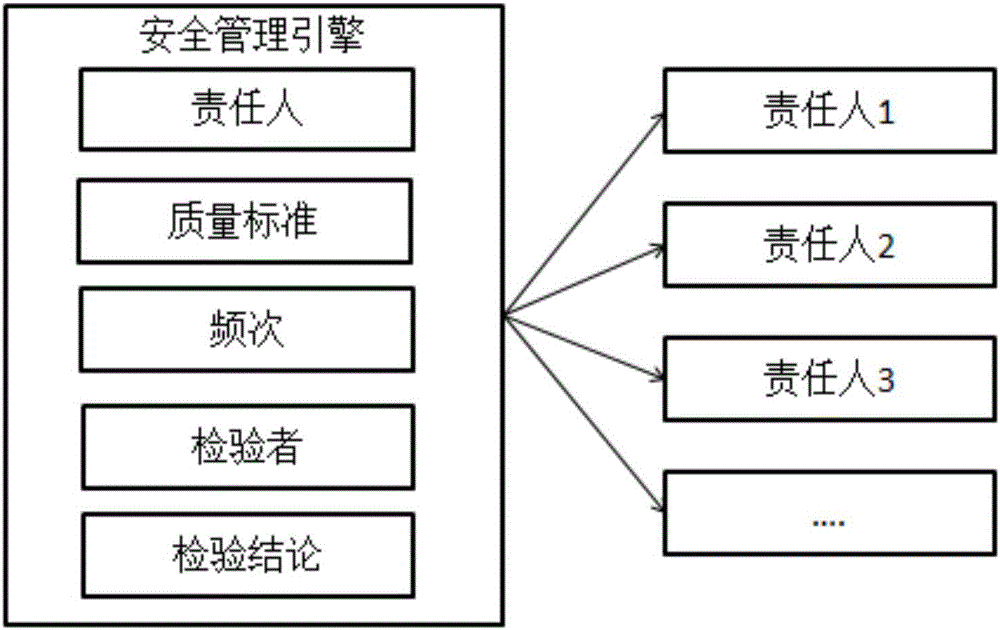

Enterprise security management system and method

InactiveCN106845819ARealize visualizationRealize visual managementResources3D modellingEnterprise security managementEngineering

The invention provides an enterprise security management system. The enterprise security management system comprises an enterprise feature selection module used for selecting enterprise features of an enterprise, a security management range determination module used for determining a security management range according to the enterprise features, a security management engine module used for performing security management engine configuration according to the determined security management range, a responsibility system driving module used for performing responsibility system driving after configuration of the security management engine module, a process recording module used for recording process information of the system, and a responsibility assessment module used for assessing a responsibility system according to the process information recorded by the process recording module. The invention furthermore provides a method of the enterprise security management system.

Owner:朗坤智慧科技股份有限公司

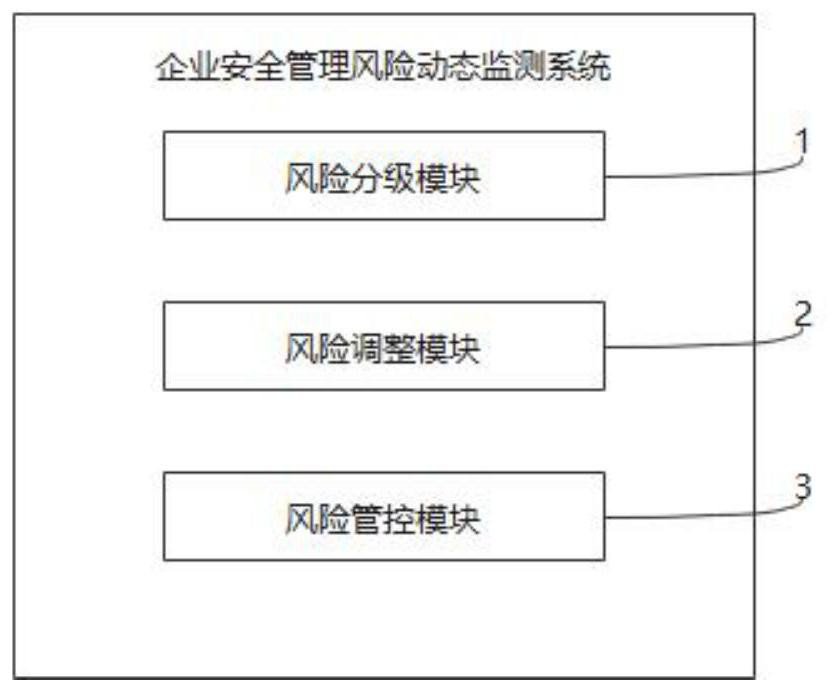

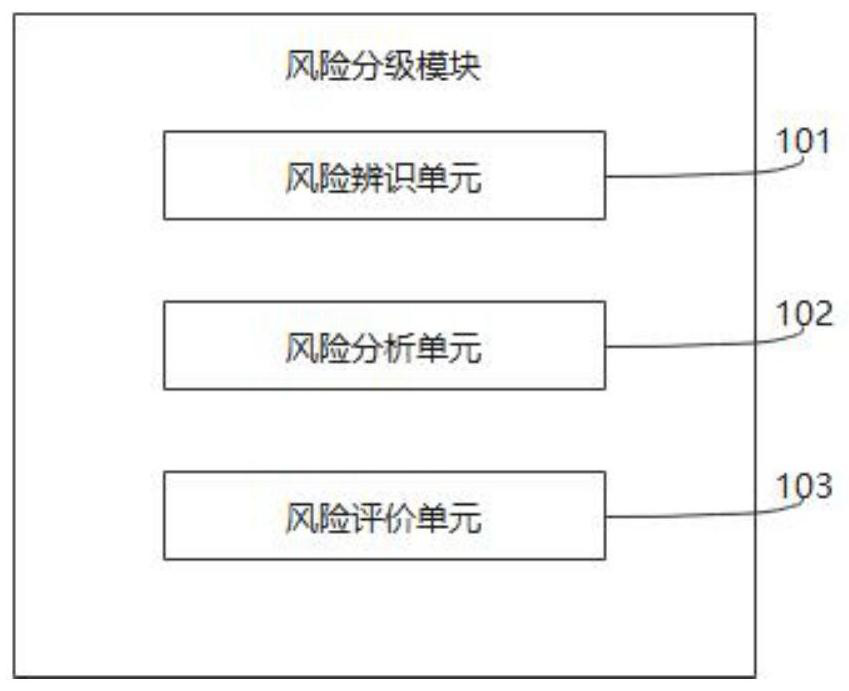

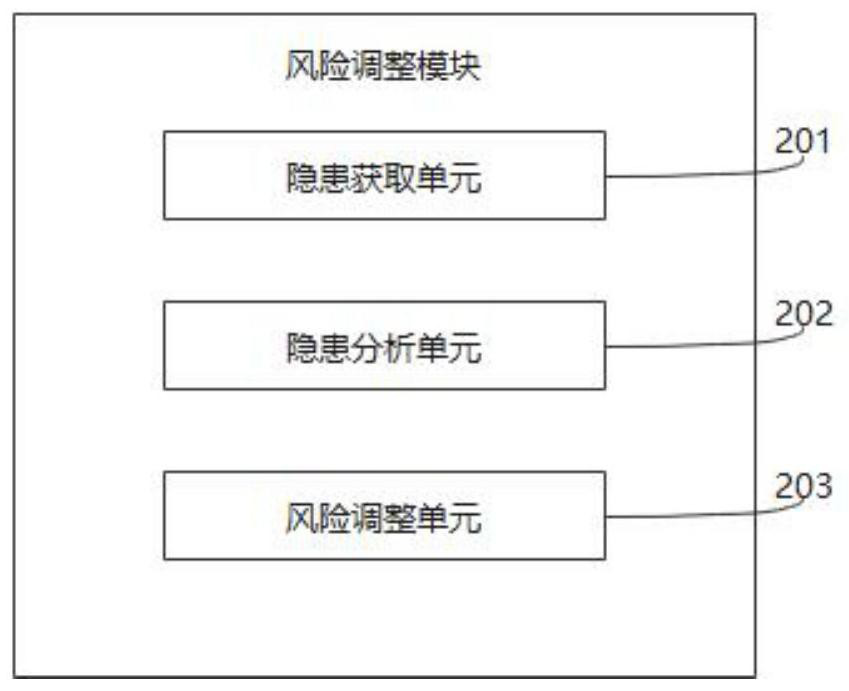

Enterprise safety management risk dynamic monitoring system

ActiveCN114139880AReduce hidden dangersPrevent safety production accidentsCharacter and pattern recognitionNeural architecturesEnterprise security managementRisk level

The invention provides an enterprise safety management risk dynamic monitoring system comprising a risk grading module used for carrying out risk grading on each work place in an enterprise to obtain an initial risk grade; the risk adjustment module is used for acquiring hidden dangers existing in the workplace and adjusting the initial risk level of the workplace according to the hidden dangers to obtain a temporary risk level; the risk management and control module is used for sending a corresponding risk signal to a worker of the corresponding level according to the temporary risk level, the system carries out monitoring management and control from the risk level by analyzing the incidence relation among the risk, the hidden danger and the accident, and safety production accidents are effectively prevented.

Owner:CHINA ACAD OF SAFETY SCI & TECH +2

Credit system enterprise safety management method and system

PendingCN112598267AAvoid forgettingRaise security awarenessDiscounts/incentivesResourcesCredit systemEnterprise security management

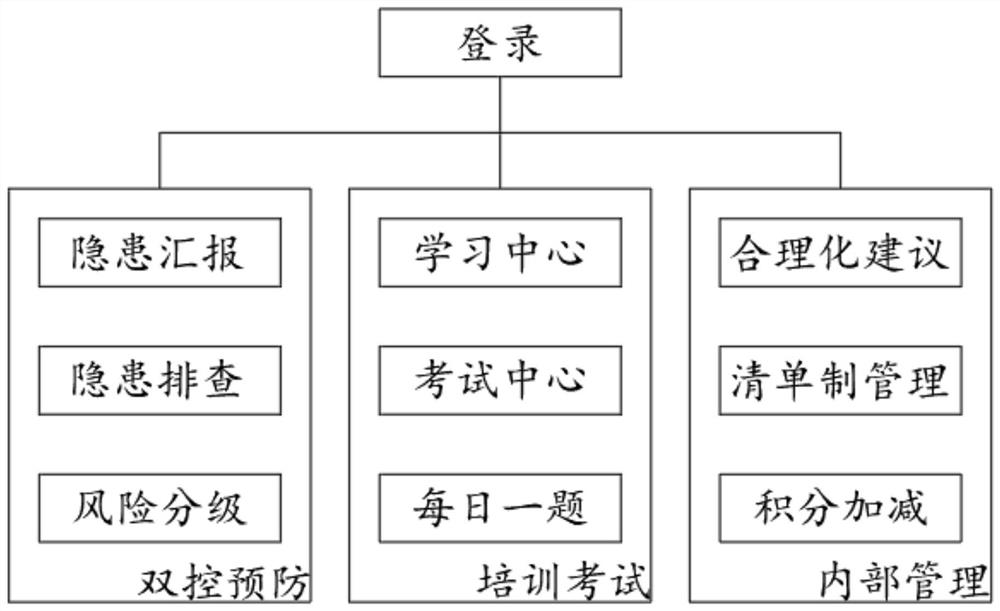

The invention provides a credit system enterprise safety management method and system, and relates to the field of enterprise management. The credit system enterprise safety management method comprises the following steps that employees obtain credits by learning safety production knowledge, reporting hidden dangers and solving the hidden dangers, exchange the credits with rewards set by enterprises, and actively improve the awareness of safety production; The credit system enterprise safety management system comprises a login part; a double-control prevention part: hidden danger reporting, hidden danger checking and risk grading; a training and examination part: a learning center and an examination center take a question every day; and an internal management part: reasonable suggestion, list system management and integral addition and subtraction. Employees are promoted to autonomously learn knowledge of safety production in an integral mode, and meanwhile, enterprise production management is facilitated.

Owner:成都慧特安全技术有限公司

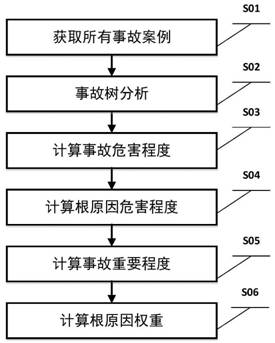

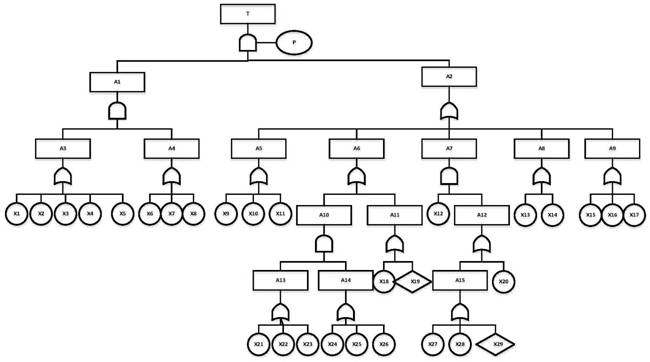

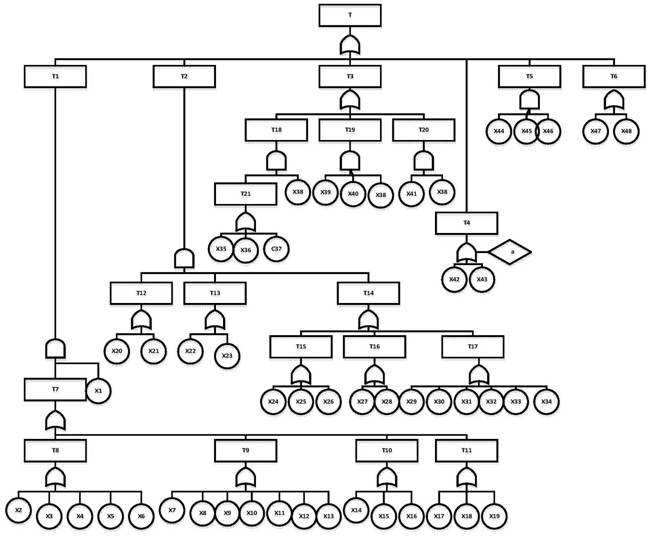

A method for assigning values to evaluation indicators of safety management level

ActiveCN110119864BImprove scienceScientific evaluation goodResourcesEnterprise security managementRoot cause

The invention discloses a safety management level evaluation index assignment method, which belongs to the technical field of safety evaluation of oil refining and chemical enterprises. The assignment method includes: obtaining all accident cases, obtaining the number n of major accidents related to all refining and chemical enterprises; analyzing all accidents through the fault tree and obtaining the root cause event R of each accident ij , where i is the i-th major accident, j is the j-th root cause of the i-th accident; calculate the accident hazard degree w i That is, the quantified value of the accident hazard degree of the i-th major accident; calculate the root cause hazard degree f 1 (i, j) is the structural damage degree of the root cause of the jth type in the ith major accident. The safety management level evaluation index assignment method of the present invention increases the scientificity of the evaluation index weight quantification, and can also solve the problem of unstable demand through an iterative process, and can better scientifically evaluate the safety management of refining and chemical enterprises.

Owner:CHINA PETROLEUM & CHEM CORP +1

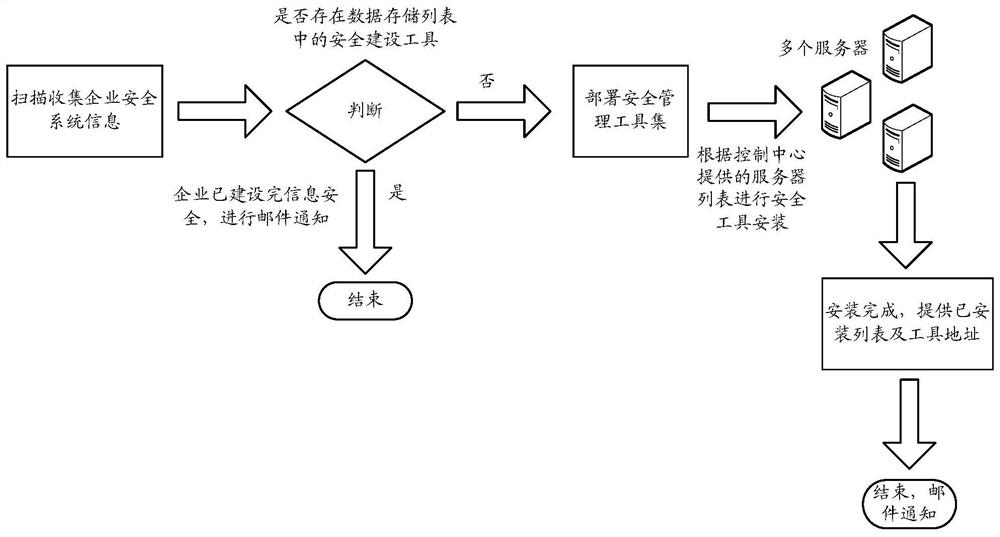

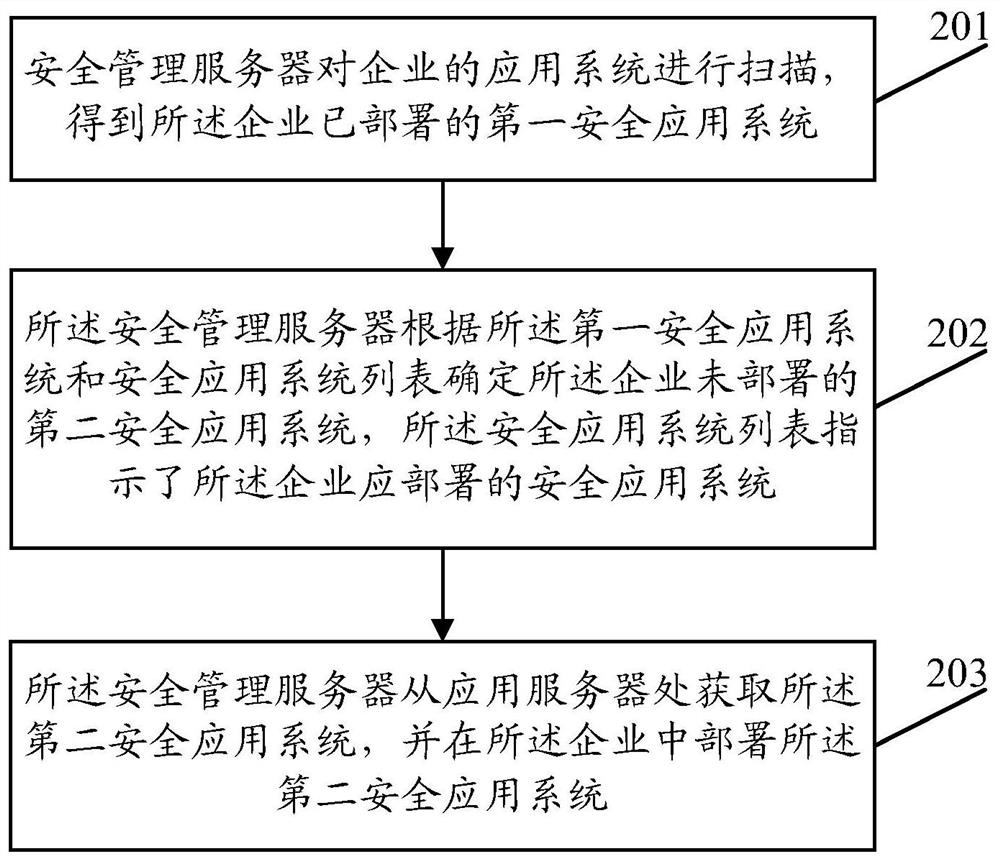

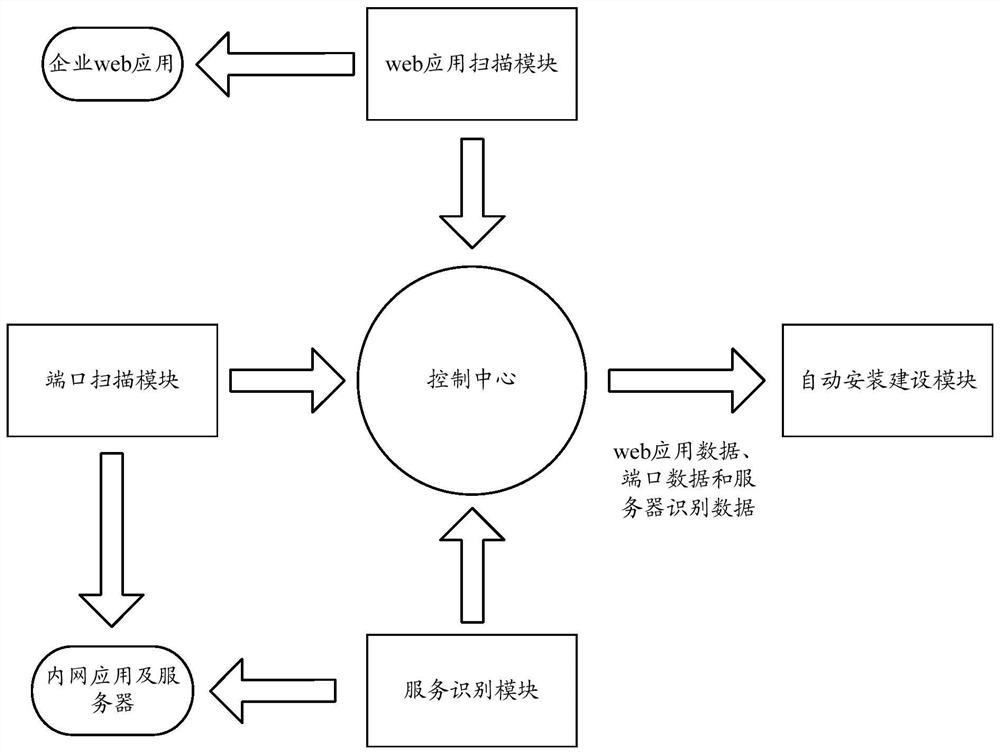

Enterprise security management method, device and security management server

ActiveCN110875900BEfficient constructionEfficiently complete the constructionSecuring communicationEnterprise security managementApplication server

An embodiment of the present invention provides an enterprise security management method, device, and security management server, wherein the method includes: scanning the application system of the enterprise to obtain the first security application system deployed by the enterprise, according to the first security application system and the security The application system list determines the second security application system not deployed by the enterprise, wherein the security application system list indicates the security application system that the enterprise should deploy, and then obtains the second security application system from the application server, and Deploy the second security application system. Through the embodiment of the present invention, the construction of the enterprise security application system can be completed automatically and efficiently.

Owner:SIMPLECREDIT MICRO LENDING CO LTD

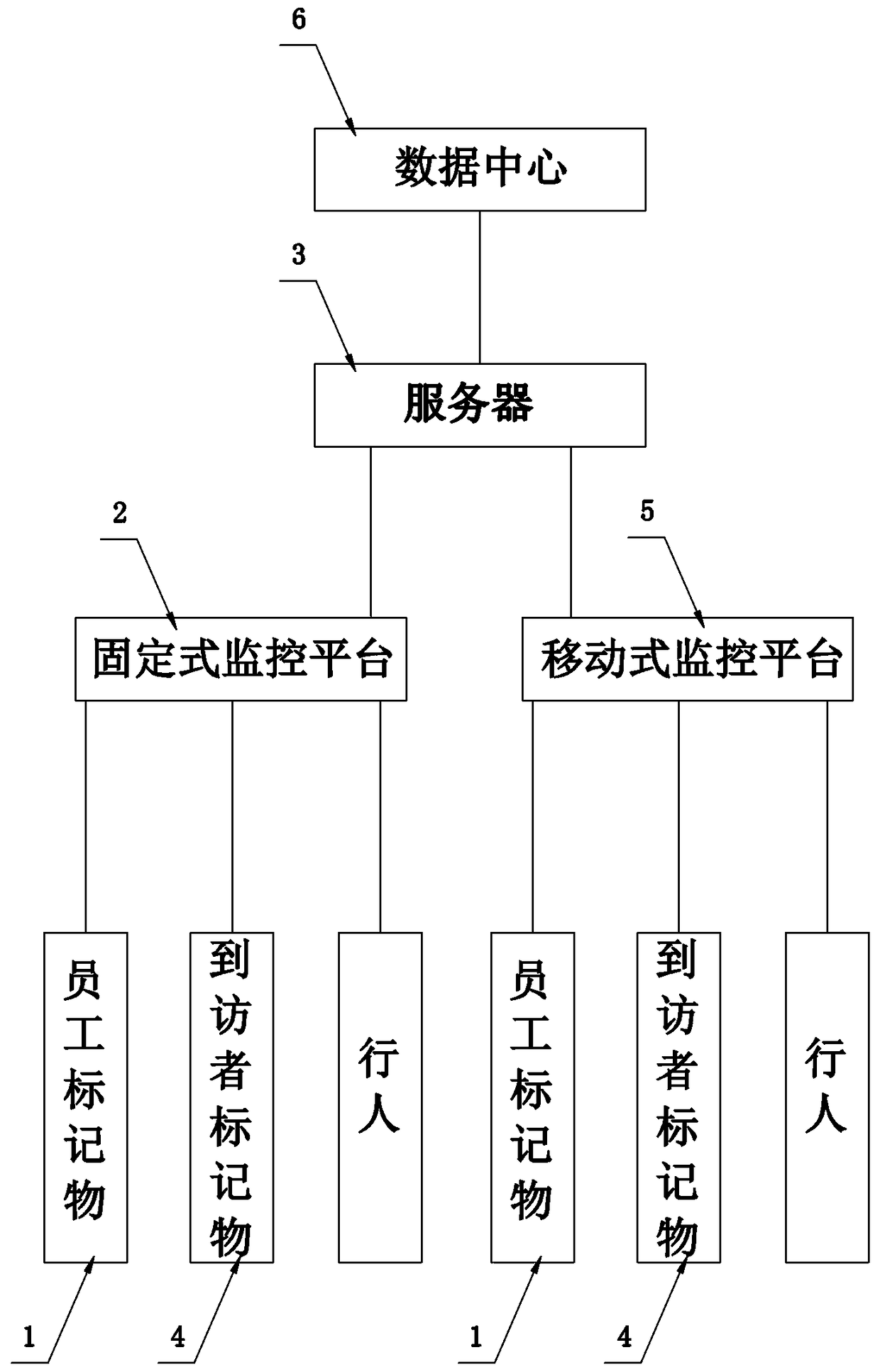

A method used in an intelligent material connection management system of a large-scale enterprise

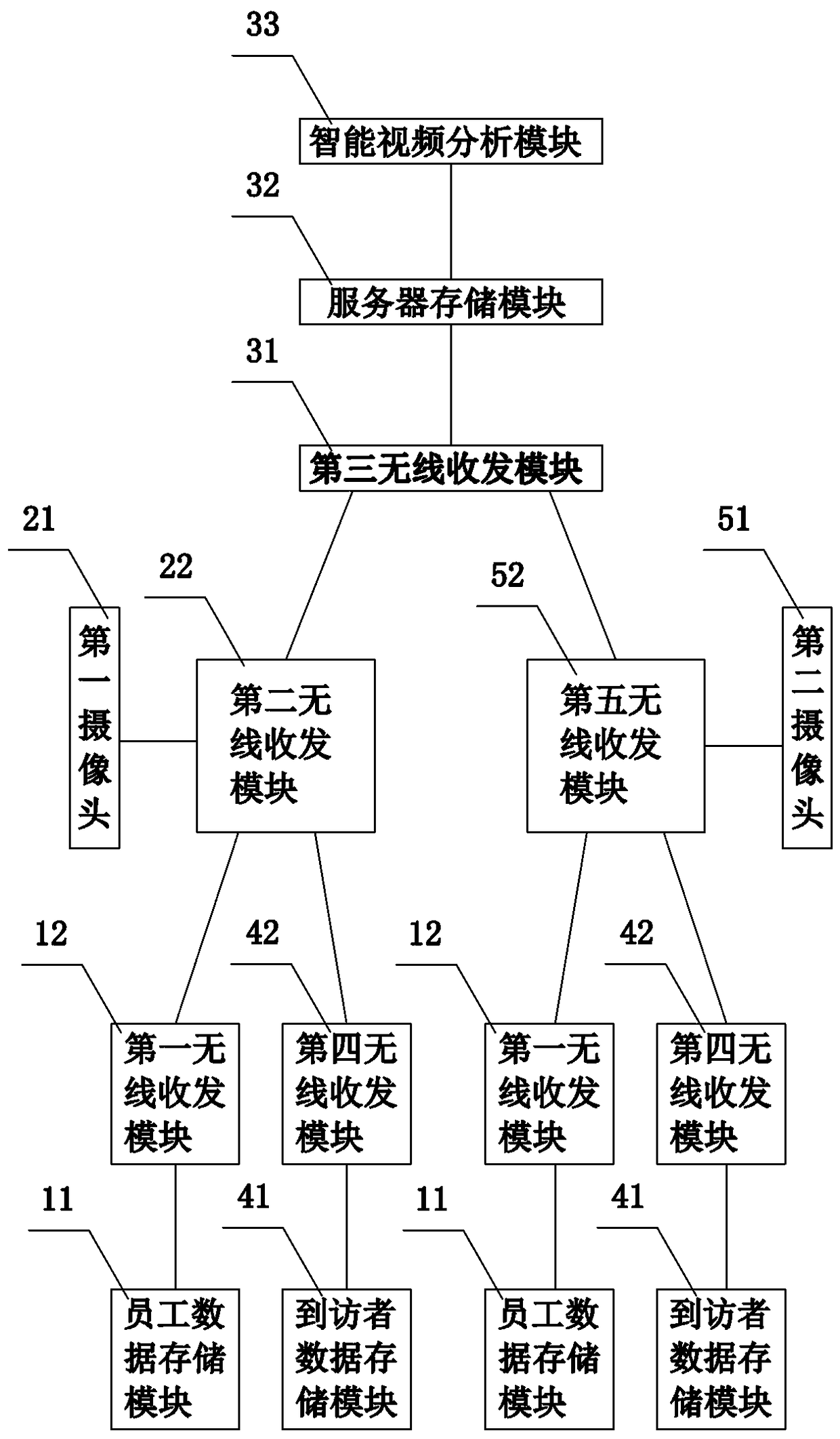

InactiveCN109446766AEffective monitoringSimple structureClosed circuit television systemsDigital data authenticationEnterprise security managementAutomatic control

The utility model relates to a method used in an intelligent material connection management system of a large-scale enterprise, which comprises a plurality of employee markers respectively installed on the bodies of employees of each enterprise, and a plurality of fixed monitoring platforms and servers respectively installed on the facilities of the enterprise. The employee marker stores corresponding employee personal information. By setting employee markers, stationary monitoring platform, the servers cooperate with each other, so that the fixed monitoring platform can send the pedestrian image information collected in the signal receiving range of the monitoring platform and the employee personal information to the server for matching. If the pedestrian image information does not matchthe employee's personal information, the server can automatically control the fixed monitoring platform to take photos and videotape, so as to effectively supervise the suspicious personnel in the enterprise, and avoid the situation that the technical secret is stolen or the production safety is threatened, which is bound to be a qualitative improvement for the safety management of the current enterprise.

Owner:福建省南安市大大电子有限公司

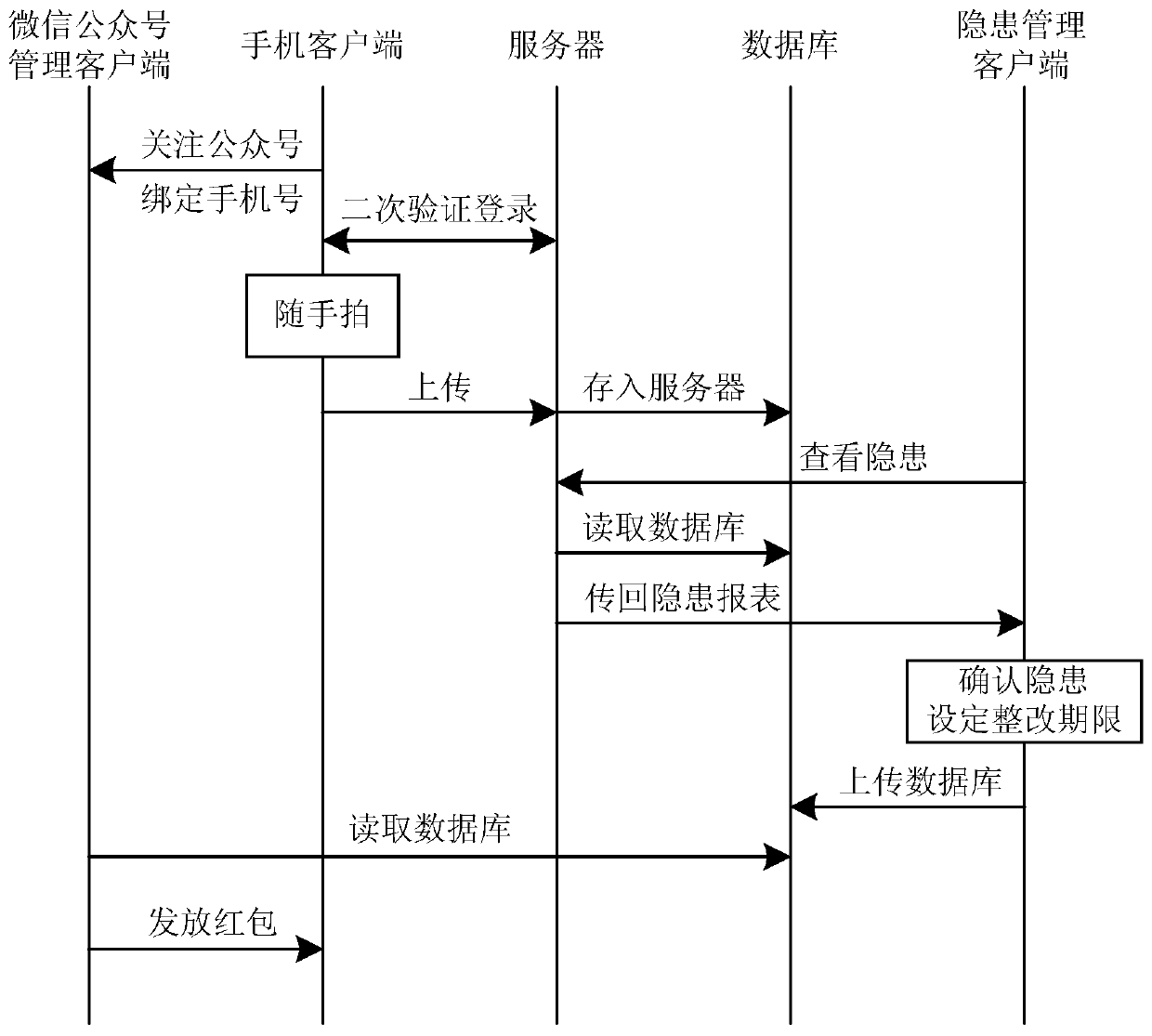

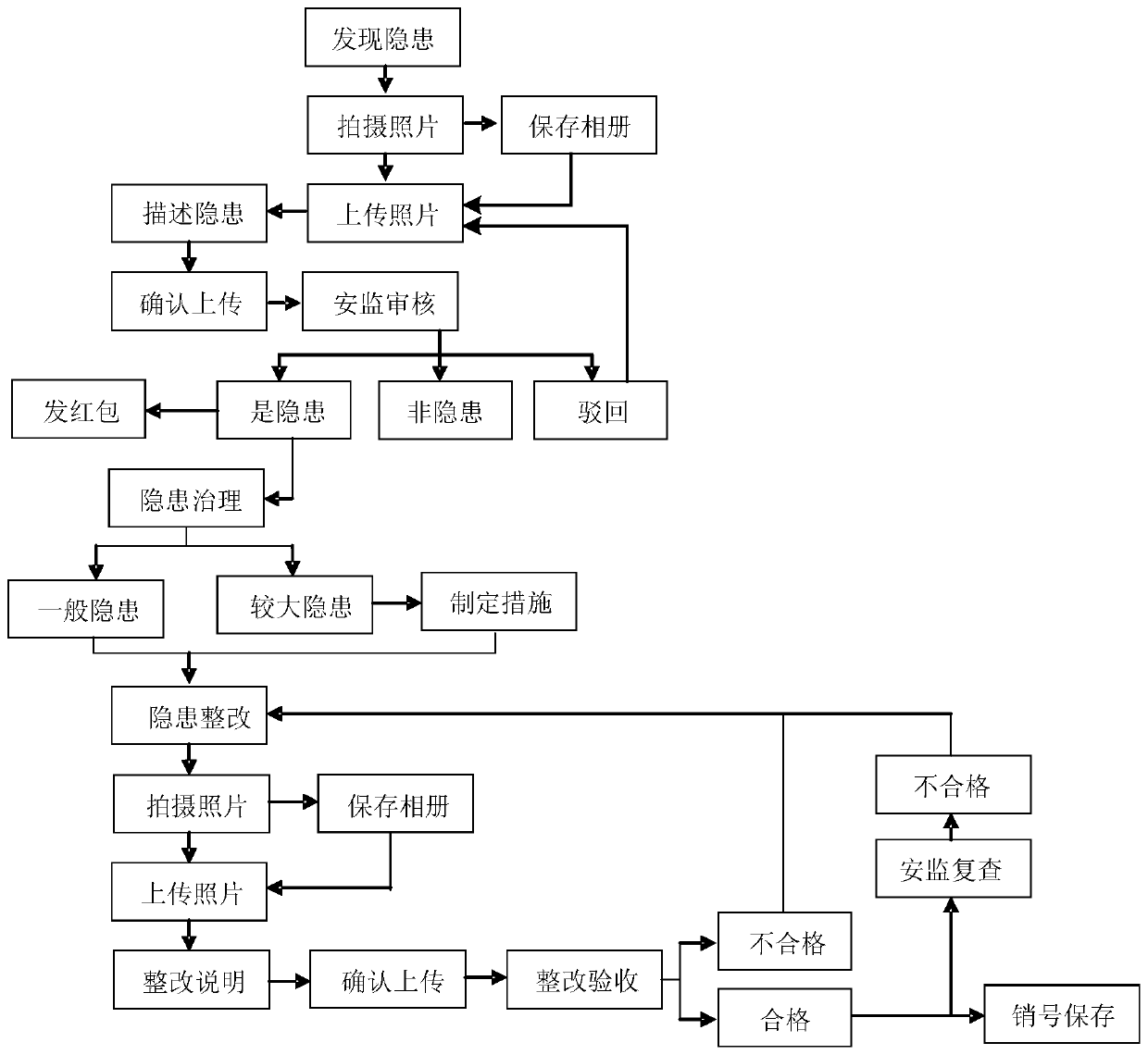

Whole-person potential safety hazard troubleshooting method and system

PendingCN110490441AEffectively collect potential safety hazardsEasy to implementCo-operative working arrangementsComputer security arrangementsEnterprise security managementSocial benefits

The invention discloses a whole-person potential safety hazard troubleshooting method and system, and belongs to the technical field of Internet + security management. The system comprises a mobile phone client, a server, a database, a hidden danger management client and a WeChat official account management client. The method is based on the mobile internet technology, and is easy to implement andconvenient to operate. The system has a reward mechanism, can fully launch employees and effectively collect potential safety hazards, is a novel enterprise safety management mode of Internet + safety management, solves the problems of potential safety hazards of employees, poor safety awareness, low safety management efficiency and the like in the prior art, and has good social benefits and promotional values.

Owner:HEBEI NINGFANG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com