Liquid storage tank liquid level control method based on fractional order state spatial prediction function control

A technology of predictive function control and state space, applied in the field of automation, can solve the problems that the control accuracy and product requirements of the distillation tower cannot be met, and the control effect of the fractional order system model is not very good, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Take the liquid level control of the liquid storage tank in the actual production process of the distillation tower as an example:

[0056]The fractional order model is obtained from the real-time liquid level data of the liquid storage tank, and the adjustment method of the liquid storage tank liquid level control system is the opening of the valve to control the cooling water flow in the distillation process.

[0057] Step 1. Establish a fractional-order state-space model of the liquid level of the liquid storage tank in the actual production process of the distillation tower, specifically:

[0058] 1.1 Collect the real-time input and output data of the liquid level of the liquid storage tank during the distillation process, and establish the fractional state space model of the liquid level of the liquid storage tank:

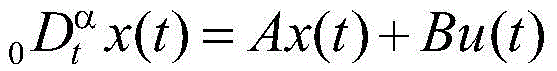

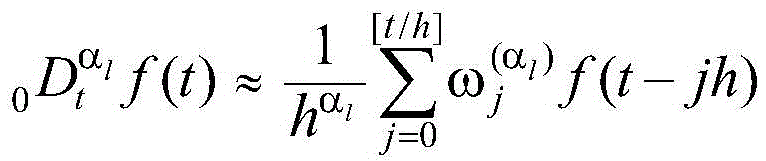

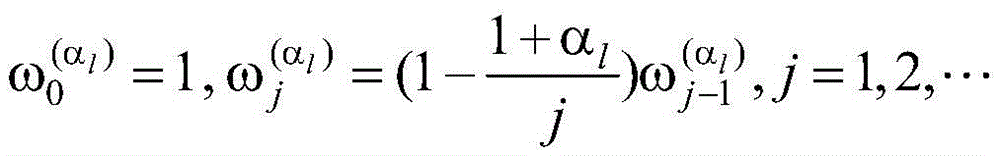

[0059] D t α 0 x ( t ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com