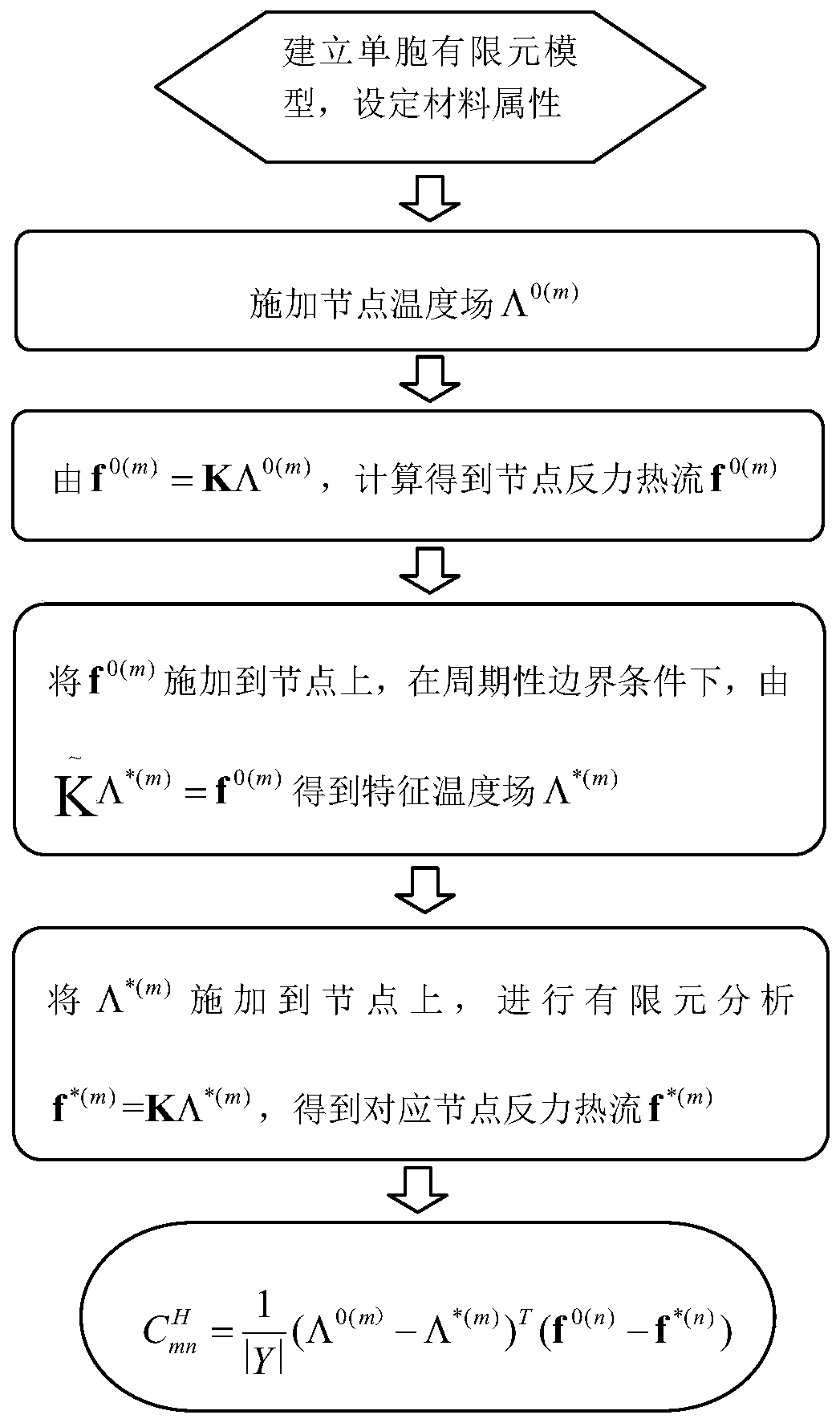

A Simple Realization Method for Predicting Thermal Conductivity of Periodic Composites by Progressive Homogenization

A thermal conductivity, composite material technology, applied in design optimization/simulation, electrical digital data processing, special data processing applications, etc., can solve the problems of complex implementation process, poor versatility and low efficiency of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

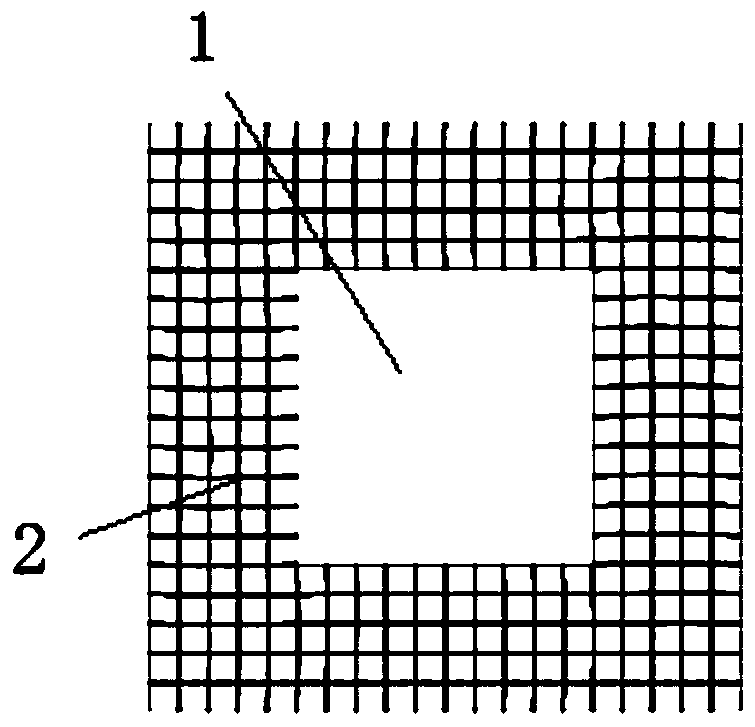

[0059] Such as figure 1 with figure 2 As shown, the interior of the unit cell containing square fiber-reinforced composite material is reinforced fiber item 1, and the exterior is resin matrix 2. The calculation of the thermal conductivity of the unit cell containing square fiber-reinforced composite material has the following steps:

[0060] S1. Establish a unit cell finite element model through commercial finite element software, and set the material thermal conductivity of the unit cell finite element model;

[0061] S2. Dividing the unit cell finite element model into a finite element mesh to obtain node and element information of the unit cell finite element model;

[0062] S3. Determine the initial temperature field Λ from the node coordinate values of the unit cell finite element model 0(m) for:

[0063]

[0064]

[0065] in, m={1,2},x i ,y i is the coordinate value of the i-th node, and N represents the total number of nodes of the unit cell finite elem...

Embodiment 2

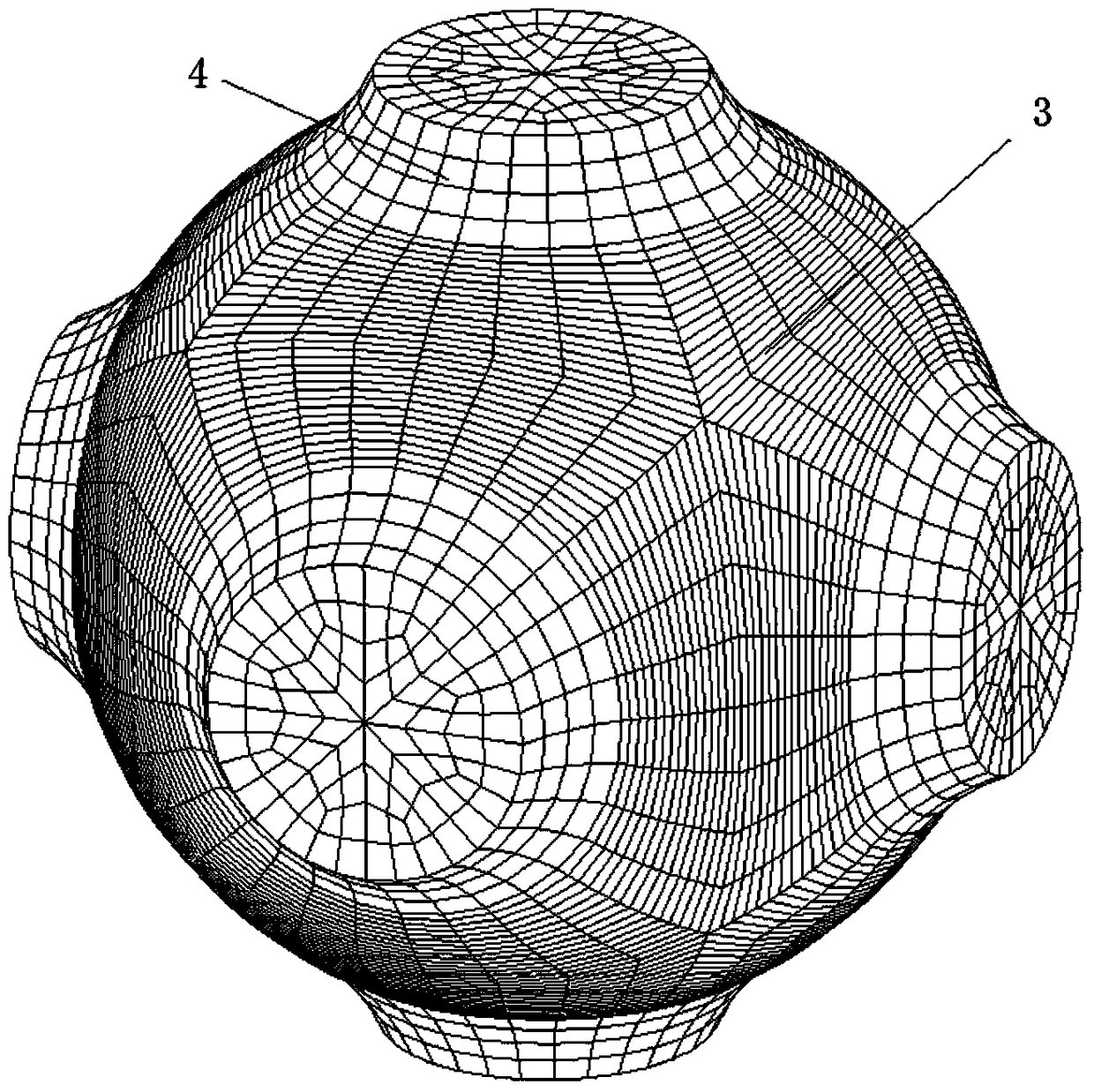

[0081] Such as figure 1 with image 3 As shown, the middle of the hollow spherical structure unit cell is a metal shell 3 (Al or new material St) with a certain thickness, and the outside is a binder material 4 (resin). The calculation of the thermal conductivity of the hollow spherical structure unit cell has the following steps:

[0082] S1. Establish a unit cell finite element model through commercial finite element software, and set the material thermal conductivity of the unit cell finite element model;

[0083] S2. Dividing the unit cell finite element model into a finite element mesh to obtain node and element information of the unit cell finite element model;

[0084] S3. Determine the initial temperature field Λ from the node coordinate values of the unit cell finite element model 0(m) for:

[0085]

[0086]

[0087]

[0088] in,

[0089] m={1,2,3},x i ,y i ,z i is the coordinate value of the i-th node, and N represents the total number of nodes in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com