High-flexibility buggy ladle-used cable

A ladle car, soft technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of inconvenience of moving construction units, cable damage, insufficient cable movement and wear resistance, and achieve good and stable signal transmission. Improved environmental stress performance and good moving tensile performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

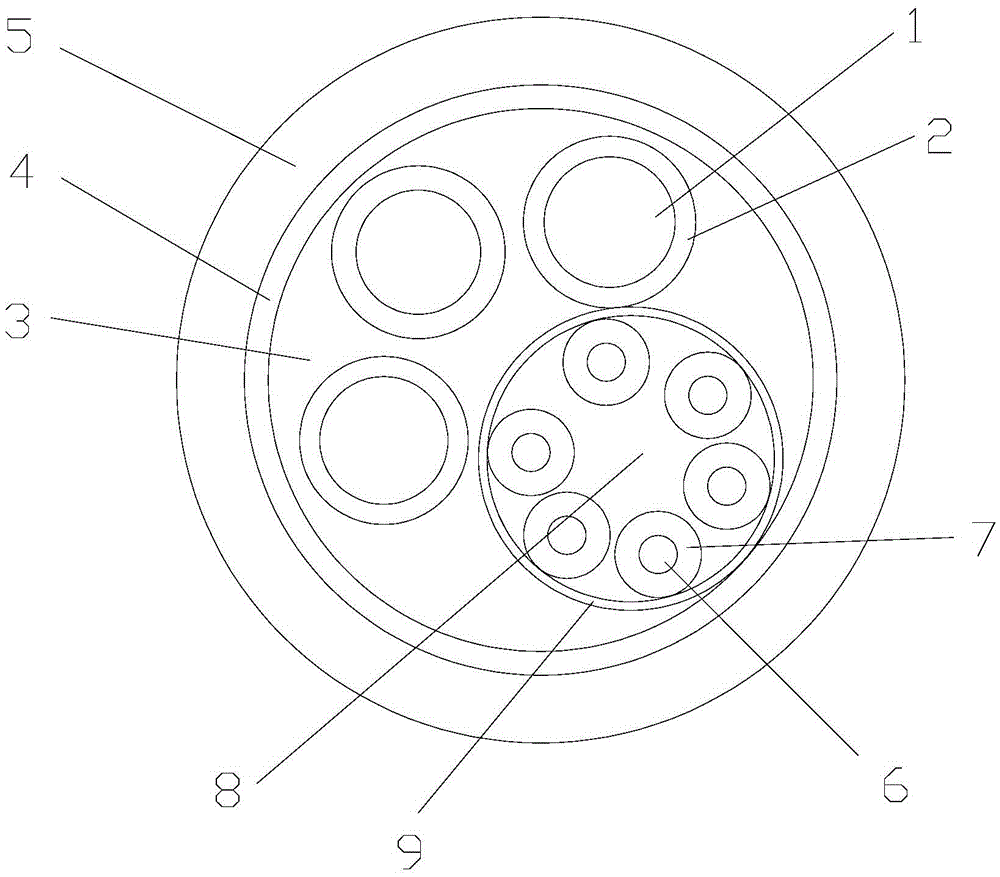

[0022] see figure 1 , the present embodiment provides a high-flexibility ladle vehicle cable, the cable is twisted into a cable core by a power system unit and a control system unit, a filling layer 3 is provided in the gap between the cable cores, and the cable core and the filling layer 3 are wrapped with The tape layer 4 and the outer sheath 5, the power system unit is composed of the first conductor 1 and the first insulating layer 2 extruded outside the first conductor 1, the control system unit is composed of multiple control system cores, filled in multiple The first filling layer 8 in the gap between the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com