Preparation method of ultraviolet-excited nano-cellulose flexible gas sensor

A nanocellulose, gas sensor technology, applied in the field of gas sensors, can solve the problems of poor flexibility of rigid substrates, inability to bend at will, and difficult to degrade substrates, and achieve good light transmission and air permeability, and good signal transmission. The effect of improving function and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

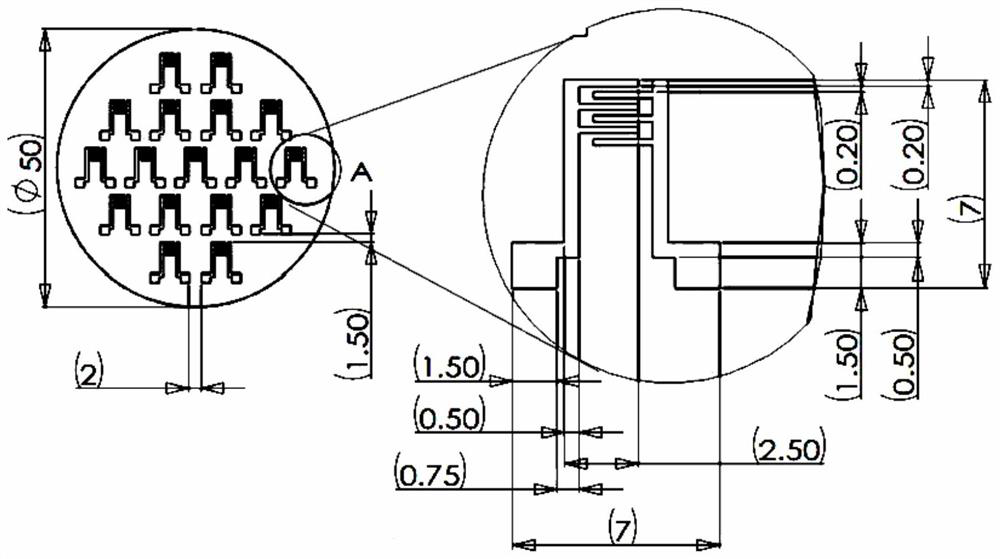

[0026] Embodiment 1: A kind of preparation method of the nanocellulose flexible gas sensor excited by ultraviolet light, comprises the following steps:

[0027] S1. Add the semiconductor nanoparticles to the nanocellulose suspension with a concentration of 1.5wt%, and ultrasonically mix for 7 minutes to form a mixed suspension; wherein the mass ratio of the semiconductor nanoparticles in the mixed suspension to the solid content of the nanocellulose is 1:20 , the bandgap range of semiconductor nanoparticles is 3.1eV-6.2eV; the bandgap (Band gap) refers to a bandgap width (unit is electron volts (ev)), the energy of electrons in solids cannot be taken continuously , but some discontinuous energy bands. To conduct electricity, there must be free electrons or holes. The energy band where free electrons exist is called the conduction band (can conduct electricity), and the energy band where free holes exist is called the valence band ( can also conduct electricity); the semiconduc...

Embodiment 2

[0030] Embodiment 2: A kind of preparation method of the nanocellulose flexible gas sensor excited by ultraviolet light, comprises the following steps:

[0031] S1. Add the semiconductor nanoparticles to the nanocellulose suspension with a concentration of 2.5wt%, and ultrasonically mix for 9 minutes to form a mixed suspension; wherein the mass ratio of the semiconductor nanoparticles in the mixed suspension to the solid content of the nanocellulose is 1:60 , the band gap range of semiconductor nanoparticles is 3.1eV-6.2eV; the semiconductor nanoparticles in this embodiment are manganese oxide nanoparticles;

[0032] S2. Use a 0.15 μm microporous membrane for vacuum filtration, first add 2ml of mixed suspension for vacuum filtration to form a layer of nanocellulose film to prevent semiconductor nanoparticles from penetrating the microporous membrane, then add 10ml of mixed suspension The liquid was subjected to vacuum filtration to obtain the intermediate, and then the interme...

Embodiment 3

[0034] Embodiment 3: A kind of preparation method of the nanocellulose flexible gas sensor excited by ultraviolet light, comprises the following steps:

[0035] S1. Add semiconductor nanoparticles to the nanocellulose suspension with a concentration of 2.2 wt%, and ultrasonically mix for 9 minutes to form a mixed suspension; wherein the mass ratio of the semiconductor nanoparticles in the mixed suspension to the solid content of nanocellulose is 1:80 , the band gap range of semiconductor nanoparticles is 3.1eV-6.2eV; the semiconductor nanoparticles in this embodiment are arsenic oxide nanoparticles;

[0036]S2. Use a 0.1 μm microporous filter membrane for vacuum filtration, first add 1.5ml of mixed suspension for vacuum filtration to form a layer of nanocellulose film to prevent semiconductor nanoparticles from penetrating the microporous filter membrane, then add 15ml of mixed suspension The suspension was vacuum filtered to obtain the intermediate, and then the intermediate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com