Method for improving uniformity of ion beams of large-parameter ion source

An ion source, uniformity technology, applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problems of reducing the efficiency of the ion source, long cycle, difficulty and so on, and achieve the effect of improving beam uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the drawings and specific embodiments of the specification.

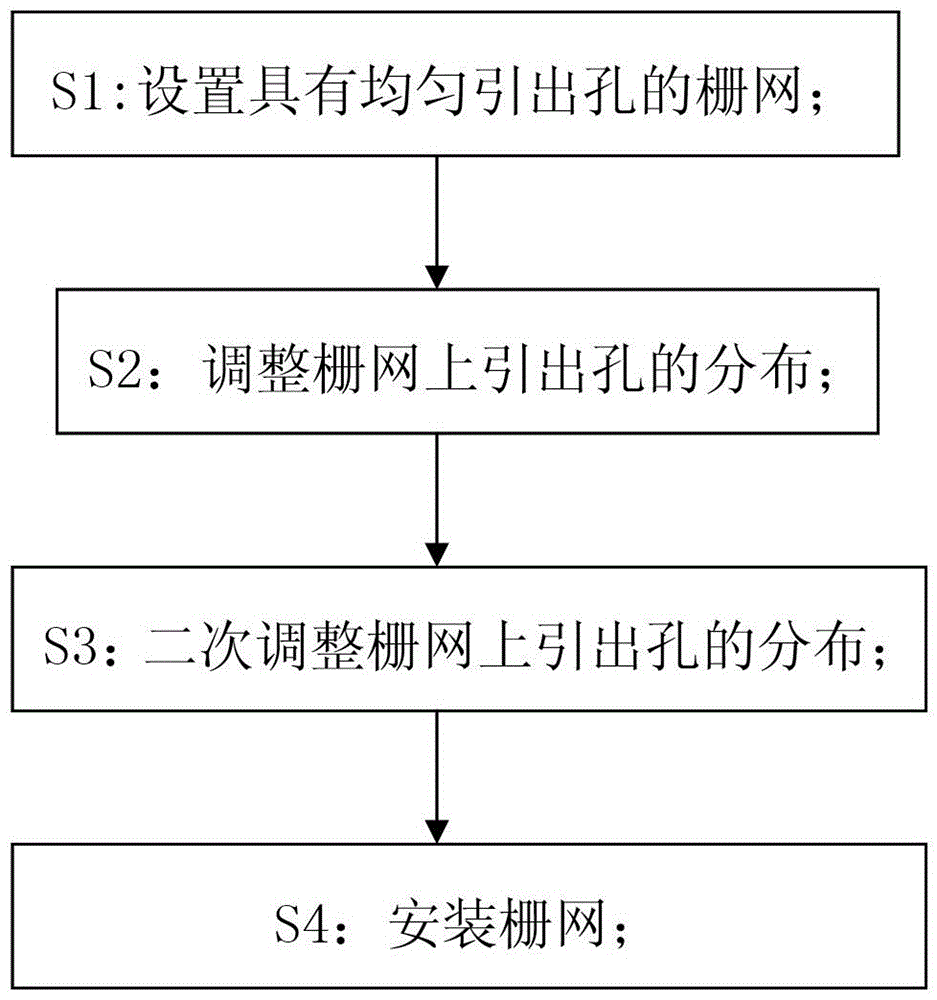

[0023] Such as figure 1 As shown, the method for improving the uniformity of ion beam current of a large-aperture ion source of the present invention includes the following steps:

[0024] S1: Set up a grid with lead holes;

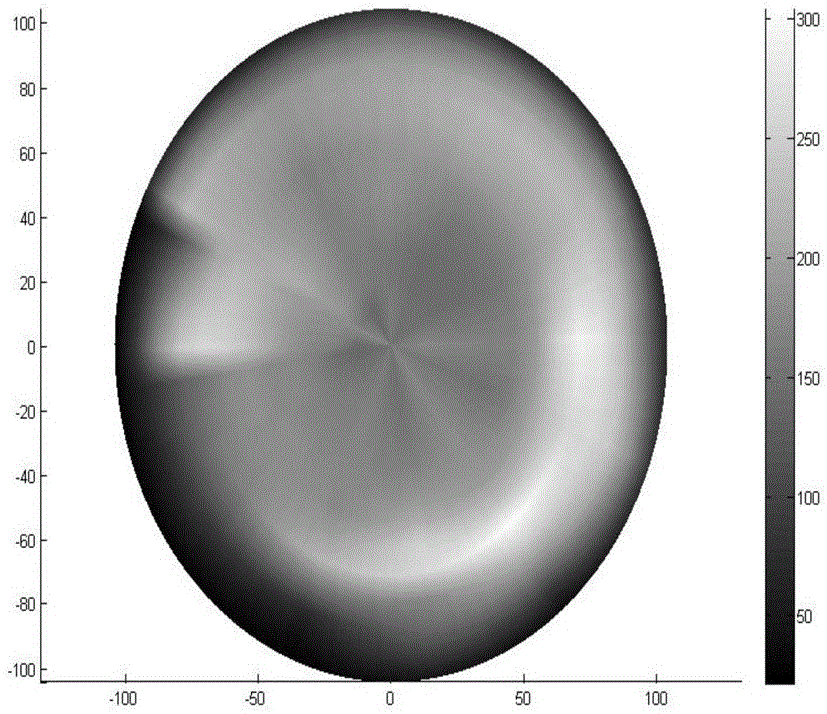

[0025] A grid with evenly distributed extraction holes is used and installed at the beam outlet position of the ion source discharge chamber. Test the beam density uniformity and draw the beam density distribution diagram A.

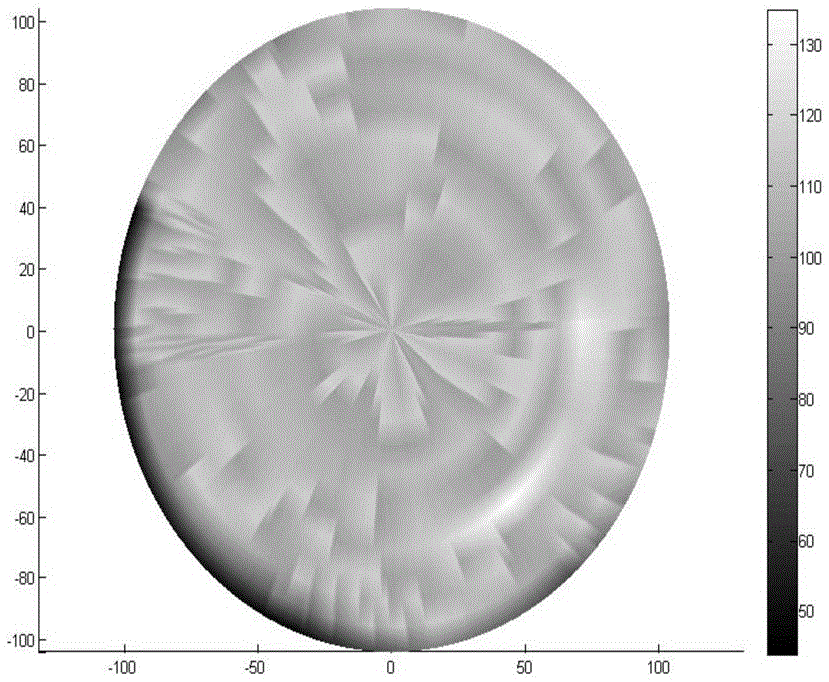

[0026] S2: Adjust the distribution of lead holes on the grid;

[0027] According to the beam density distribution diagram A, adjust the distribution of the lead-out holes on the grid. The lead-out holes should be appropriately reduced in the positions with high beam current density, and the lead-out holes should be appropriately increased in the positions with high beam current density.

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com