Optical system that detects the size and shape of fine particles with improved measurement accuracy

A technology of tiny particles and measurement accuracy, applied in the field of optical sensors, can solve the problems of affecting detection accuracy, complex optical path layout structure, poor light uniformity in the photosensitive area, etc., to improve detection accuracy, improve beam uniformity, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

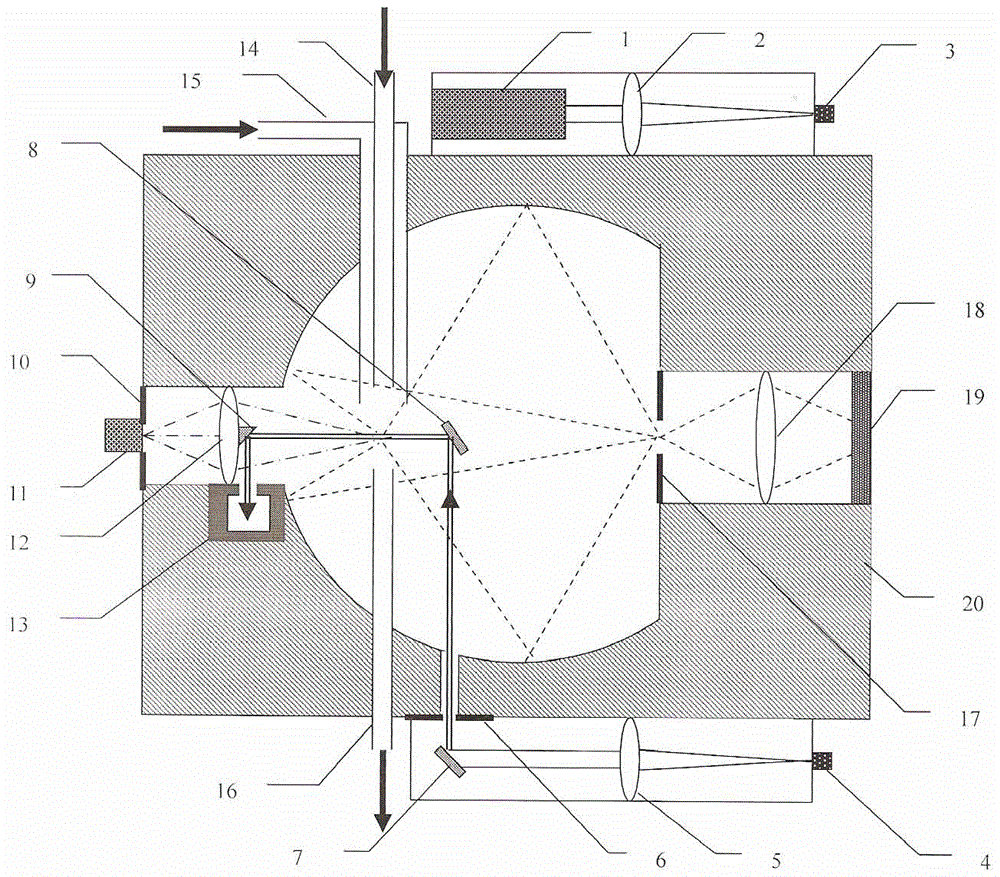

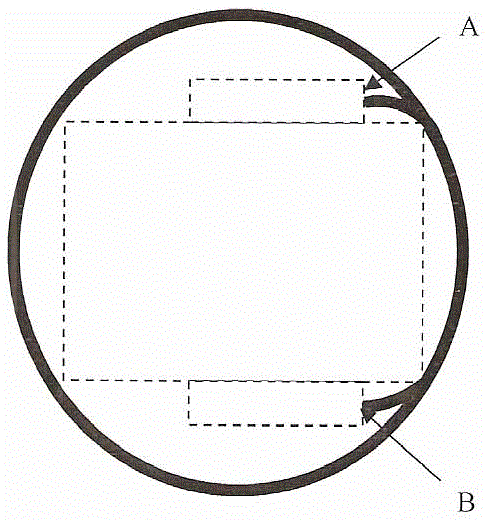

[0017] An optical system for detecting the size and shape of tiny particles, including a spherical cavity mirror 20, the spherical cavity mirror is made of metal, and the inner surface is polished and coated with a reflective film, and a laser is fixed on the outer frame of the spherical cavity mirror, And after a certain optical path layout, the optical fiber uniformity device forms a parallel beam with good uniformity, which is incident on the photosensitive area along the main axis of the spherical cavity mirror, and the incident beam and sample gas flow converge in the photosensitive area, that is, an object point of the spherical cavity mirror , the forward scattered light passes through the lens 12 and is received by the photomultiplier tube 11 after passing through the first diaphragm 10, and the incident light beam in the original direction enters the light trap 13 through the reflector 9; the light trap is made of metal, and the inner wall is coated There is a light-ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com