Elastic sheet type camera for electronic product

A technology of electronic products and cameras, which is applied in the field of shrapnel cameras for electronic products, can solve the problems of time-consuming assembly, positioning deviation, and rising costs, and achieve the effects of reducing costs, realizing production capacity, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

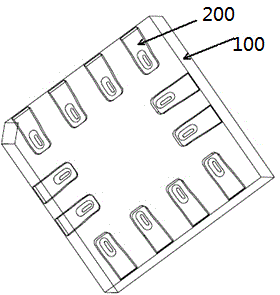

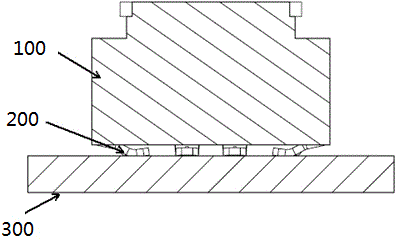

[0026] refer to figure 1 , a shrapnel camera for electronic products, comprising:

[0027] A camera body 100, the cross-section of the camera body is "convex"; the camera body includes a housing, a flexible circuit board and a chip packaged in the housing, and a lens is arranged on one side of the housing,

[0028] A plurality of elastic pieces 200 arranged on the other side of the casing, the elastic pieces are evenly distributed on the casing.

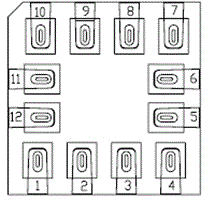

[0029] refer to figure 2 , wherein there are twelve pieces of shrapnel, including four on the upper and lower sides, and two on the left and right sides. Specifically, considering the function of the front camera, the shrapnel camera has no auto-focus function, so the number of channels is rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com