Container sterilization method and container sterilization equipment

A technology for sterilization equipment and containers, which is applied in packaging sterilization, irradiation devices, nuclear engineering, etc., can solve problems such as pollution, and achieve the effect of prolonging operation time, reducing the stoppage of sterilization equipment, and preventing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

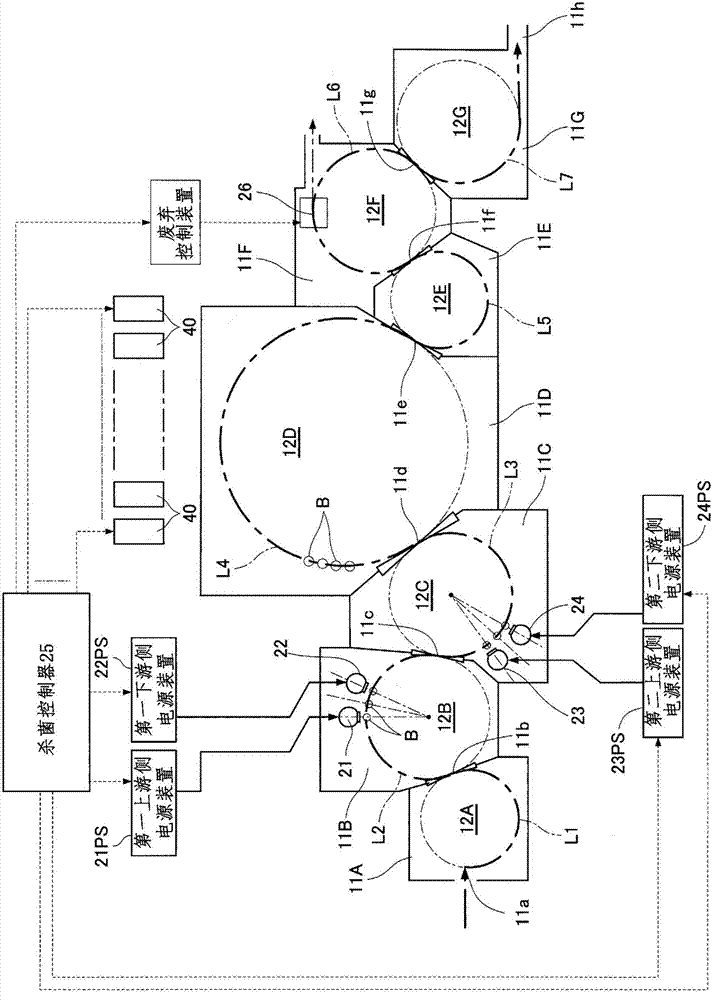

[0029] Below, according to Figure 1 to Figure 5 Embodiment 1 of the electron beam container sterilization apparatus of the present invention will be described.

[0030] (equipment overview)

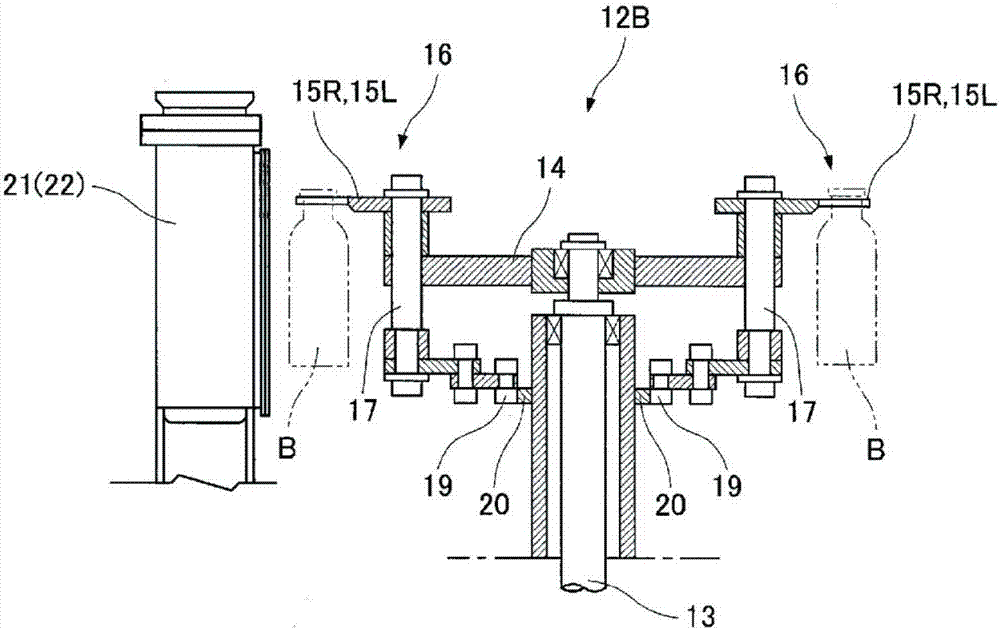

[0031] Such as figure 1 As shown, a plurality of first to seventh shielded rooms 11A to 11G are arranged in series via container inlets and outlets 11a to 11h. In the first to seventh shielded rooms 11A to 11G, first to seventh container transport devices 12A to 12G that transport containers B at a constant pitch P are installed, respectively.

[0032] The first shielded room 11A on the entrance side is formed with a circumferential container conveyance path L1 in which the containers B are conveyed by the first container conveyance device 12A. Electron beams (X-rays) are prevented from leaking to the container inlet 11a side by the first shielding room 11A.

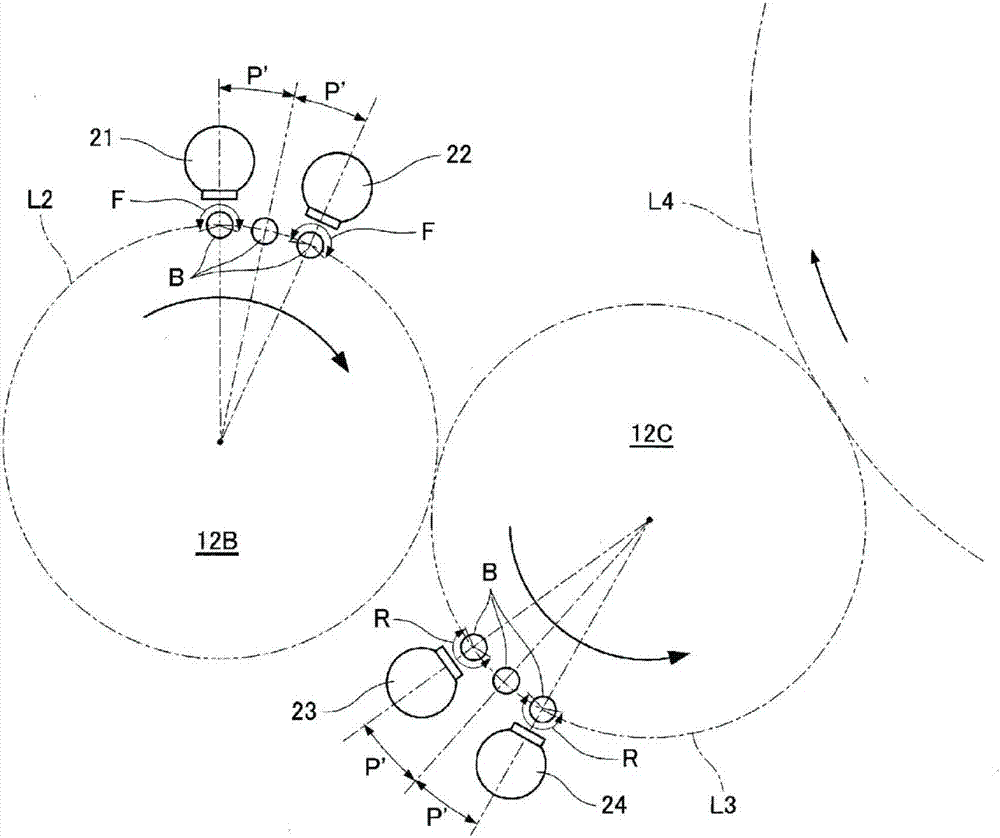

[0033] The second shield room 11B and the third shield room 11C are outer surface sterilization rooms for sterilizing the outer...

Embodiment 2

[0056] Below, according to Image 6 with Figure 7 Embodiment 2 of the electron beam container sterilization apparatus of the present invention will be described. The electron beam irradiating apparatus of the above-mentioned embodiment 2 focuses on the fact that electric sparks are likely to be generated while the vacuum degree of the vacuum chamber is lowered, and is provided with a device for detecting the vacuum degree of each vacuum chamber 30 of the above-mentioned electron ray irradiating apparatuses 21 to 24 respectively. Vacuum sensor 21VS ~ 24VS. In addition, the same code|symbol is attached|subjected to the same part as 1st Embodiment, and description is abbreviate|omitted. For example, the above-mentioned "equipment outline" and "container conveying device" have the same structure as that of the first embodiment, so the description thereof will be omitted. In addition, since the "electron beam irradiation device" has the same structure except for the vacuum sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com