UV sterilizing garbage can

A technology for sterilizing buckets and trash cans, applied in trash cans, garbage collection, garbage cleaning, etc., can solve the problems of bacteria breeding, laborious disposal of garbage, garbage falling, etc., to prevent contact infections and reduce odors. The effect of emanating, reducing emanating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

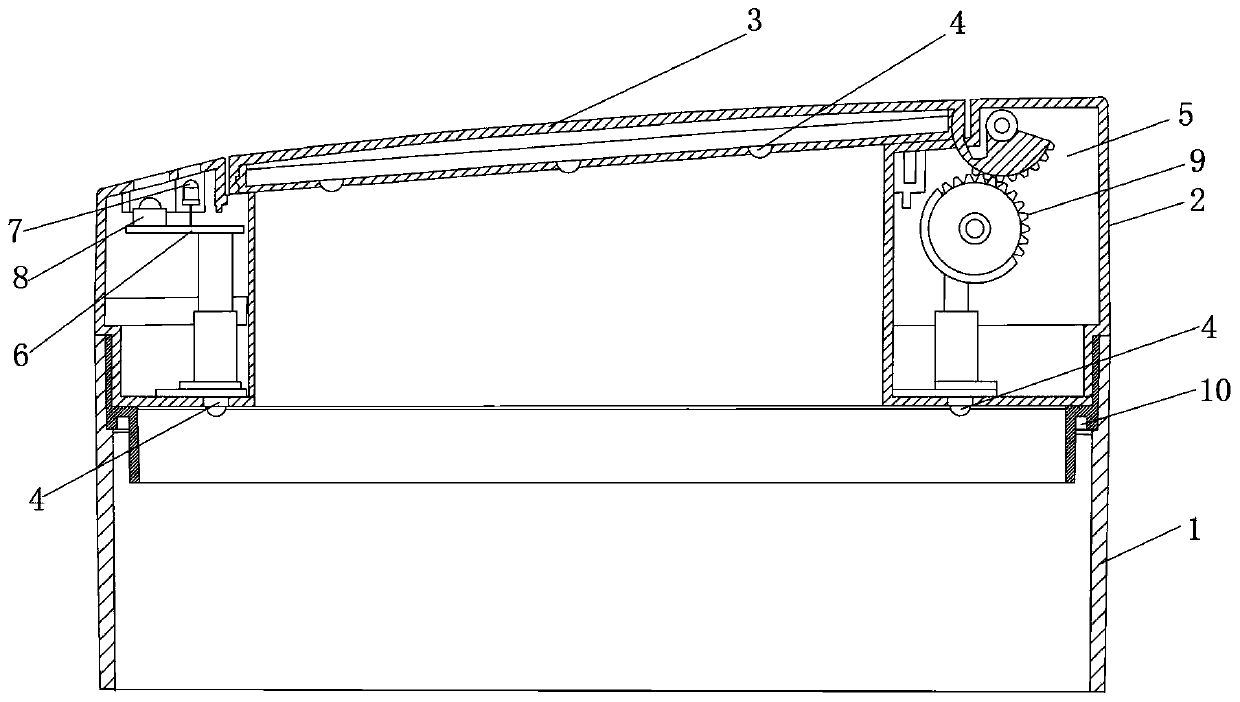

[0020] Such as figure 1 As shown, a UV sterilizing trash can includes a barrel body 1 with an open upper end, the upper port of the barrel body 1 is provided with a reversible cover body 3, and the lower end surface of the cover body 3 is provided with a UV lamp 4, The barrel body 1 is also provided with a battery assembly, and the battery assembly is electrically connected to the UV lamp 4; the upper port of the barrel body 1 is provided with a sterilization barrel 2, and the upper and lower ends of the sterilization barrel 2 are open. The reversible cover body 3 is arranged on the upper port of the sterilization barrel 2, the lower port of the sterilization barrel 2 is located inside the barrel body 1, and the outer surface of the lower end of the sterilization barrel 2 is also provided with a UV lamp 4; The inside of the barrel wall of the sterilization barrel 2 is provided with a side wall cavity 5, and the inside of the side wall cavity 5 is provided with a trigger mechan...

Embodiment 2

[0024] On the basis of the above-mentioned embodiment 1, in order to make the discharge of garbage more convenient, the connection between the sterilization barrel 2 and the barrel body 1 is improved, and the sterilization barrel 2 and the barrel body 1 are set to be detachably connected;

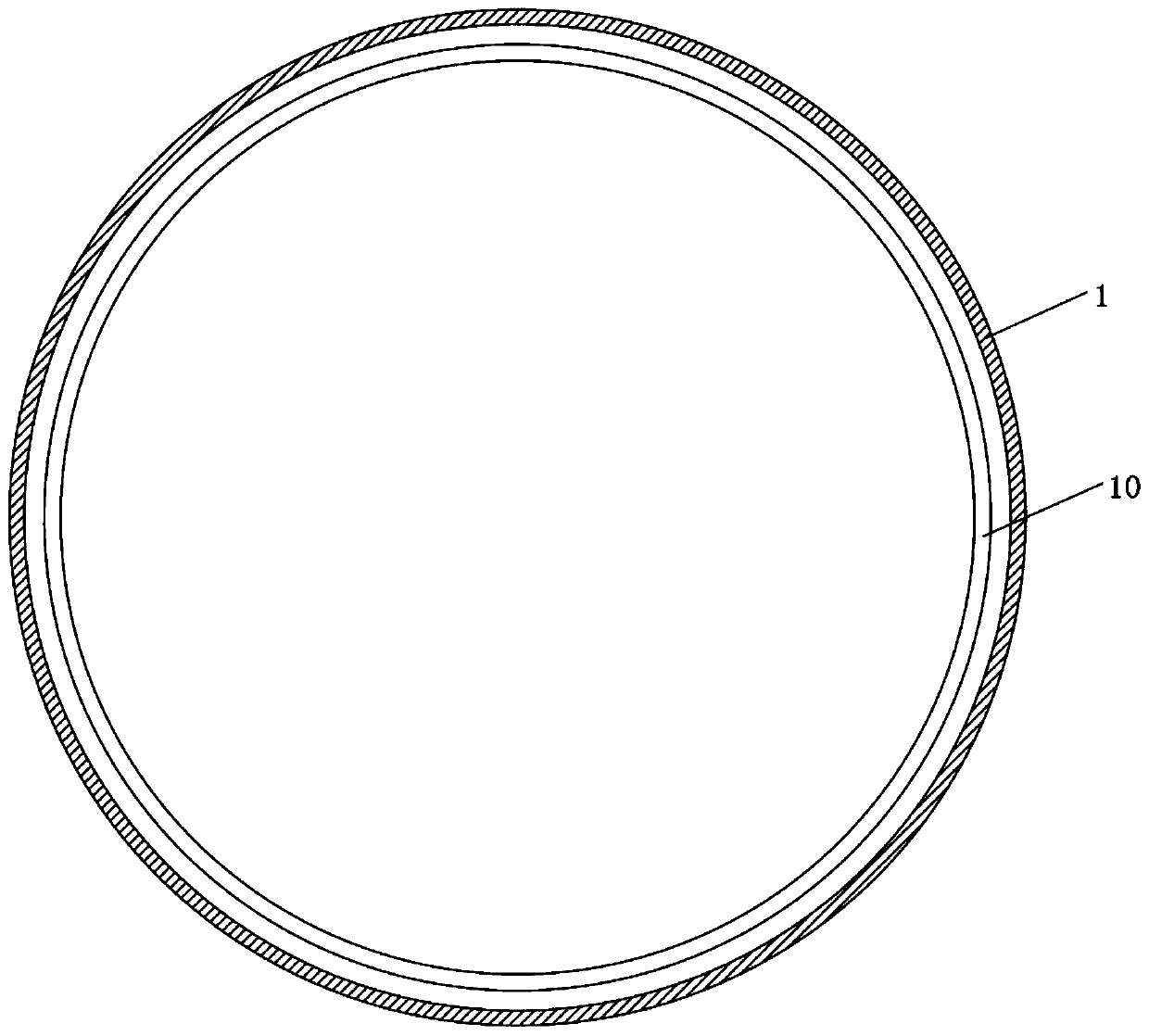

[0025] Specifically, this embodiment provides a detachable connection method, which is a buckle connection: the inner surface of the barrel body 1 is provided with a block 10, such as figure 2 As shown, the clamping block 10 forms a clamping groove with the inner wall of the barrel body 1, and the bottom of the sterilization barrel 2 is provided with an engaging structure. The cross section of the engaging structure is a "7"-shaped structure, which is engaged in the engaging groove , The part of the "7"-shaped structure that is engaged in the slot is made of elastic material and is made of hard rubber blocks, which further improves the stability between the sterilization barrel 2 and the ba...

Embodiment 3

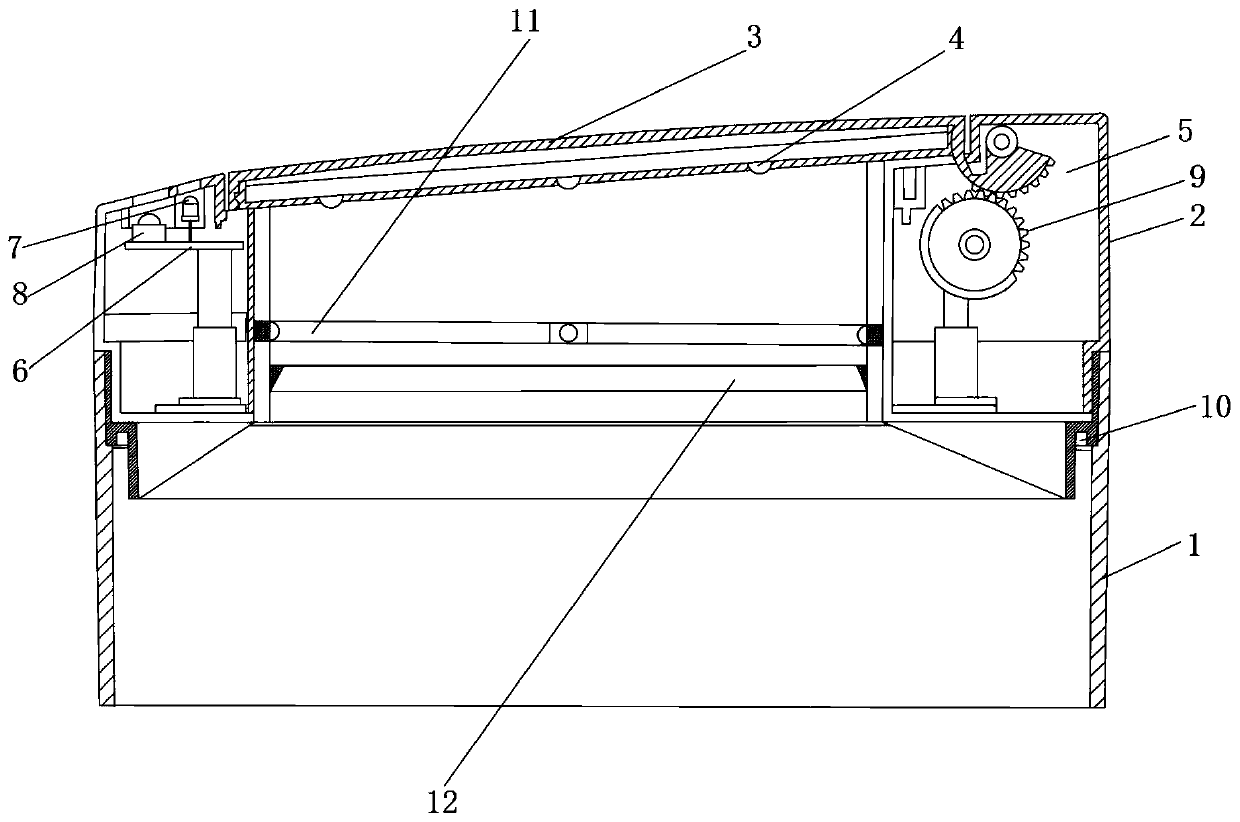

[0027] On the basis of the above-mentioned embodiment 1 or embodiment 2, due to the existence of the side wall cavity 5 of the sterilization barrel 2, the side wall has a certain thickness, so that the UV lamp 4 under the cover body 3 cannot cover the barrel body well 1, there is a certain irradiation dead angle, and in embodiment 1, the lower end surface of sterilization bucket 2 (such as figure 1 shown) is provided with a UV lamp 4, but the position where the UV lamp 4 is set is easy to contact with the garbage in the barrel body 1, and the UV lamp 4 cannot be easily disassembled and cleaned in the actual use of the trash can, so as image 3 As shown, the following improvements are made: the interior of the sterilization barrel 2 is provided with a slope structure near the lower end, the UV lamp 4 originally arranged at the lower end of the sterilization barrel 2 as in Embodiment 1 is removed, and the inner wall surface of the sterilization barrel 2 is set There is a lamp ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com