Centrifugal-type molecular distillation system

A molecular distillation and centrifugal technology, applied in the field of molecular distillation technology, can solve the problems of easy thermal deterioration and back mixing, and achieve the effects of wide application range, convenient use and simple structure

Inactive Publication Date: 2016-05-18

CHENGDU CHUANGWEIKAI TECH INFORMAITON CONSULTING CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a centrifugal molecular distillation system for the above existing problems, which mainly solves the technical problem that materials are easily deteriorated by heat during the separation process, and also solves the problems of material back-mixing and dynamic and static sealing in the molecular distillation process , is completely suitable for separating vitamin E from oil refining and deodorizing distillate. It has simple structure, easy operation, convenient use and wide application range.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0020] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

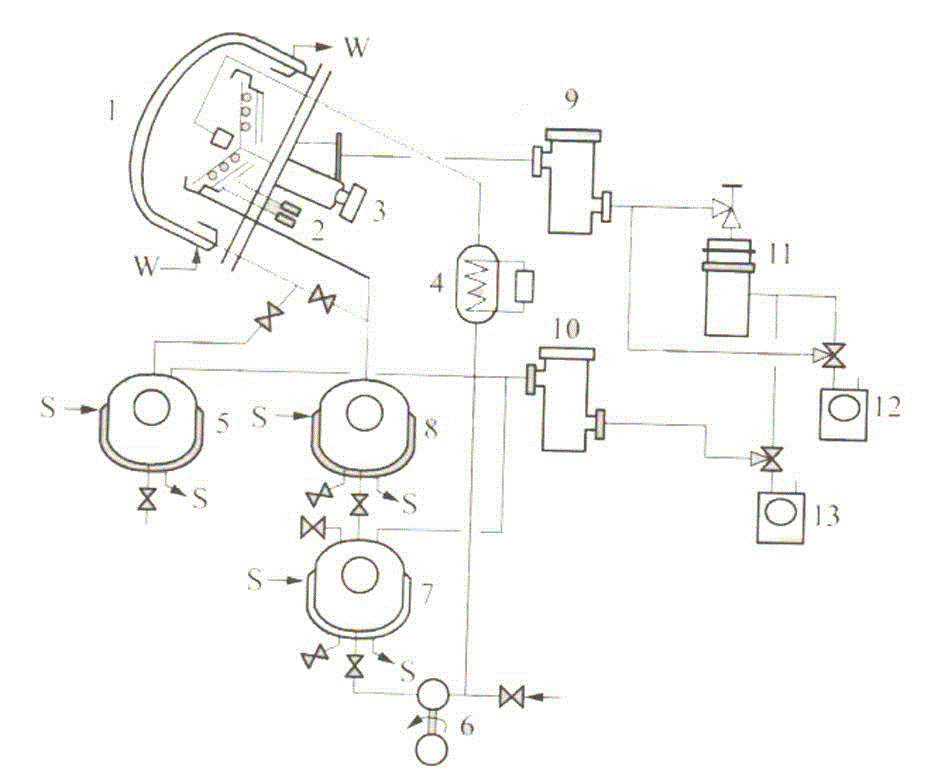

The invention discloses a centrifugal-type molecular distillation system and belongs to the technical field of food machinery. The centrifugal-type molecular distillation system mainly solves the problems that a material is liable to deteriorate when being heated during separation as well as the problems of material back-mixing and dynamic and static sealing during molecular distillation. The system is completely suitable for separating vitamin E from a grease refining and deodorization distillate. The system is simple in structure, is easy to operate, is convenient to use and has large available range. The centrifugal-type molecular distillation system includes a centrifugal-type molecular distiller, to which a material feeder, a vacuum system and a material discharge system are connected, the vacuum system being connected to the material discharge system.

Description

technical field [0001] The invention relates to the technical field of food machinery, in particular to a molecular distillation technology. Background technique [0002] In the food processing industry, sometimes it is necessary to extract another specific substance from a certain substance. For example, to separate vitamin E from oil refining deodorization distillate, it is necessary to use molecular distillation technology, that is, to extract the substance under extreme vacuum conditions. Heating, gasification, and separation within a certain period of time to achieve the purpose of purification; however, the current molecular distillation technology is backward and cannot achieve the expected purpose; however, the current molecular distillation technology has problems such as material back-mixing, dynamic and static sealing, and the material is easy to Heat deterioration. Contents of the invention [0003] The purpose of the present invention is to provide a centrifu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D3/12C07D311/72

Inventor 李伟

Owner CHENGDU CHUANGWEIKAI TECH INFORMAITON CONSULTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com