A low-pressure casting one-step method for manufacturing semi-solid light alloy castings

A low-pressure casting, light alloy technology, applied in the field of semi-solid metal processing, can solve the problems of uncontrollable, high cost, complicated operation process, etc., and achieve the effect of prolonging the free time of grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

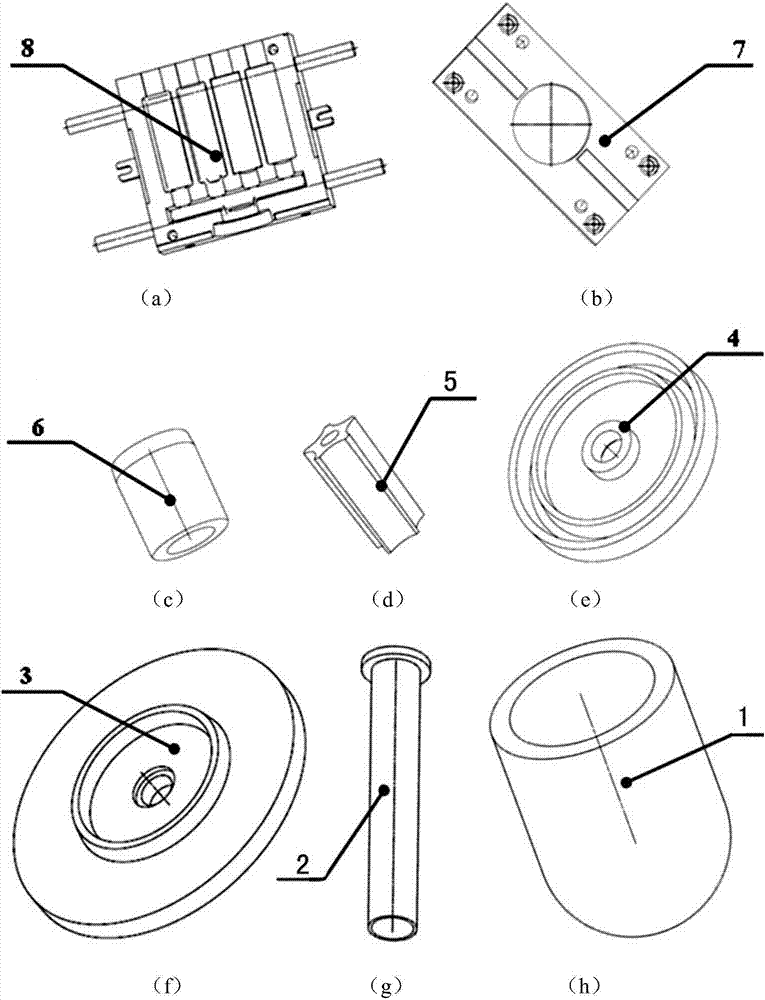

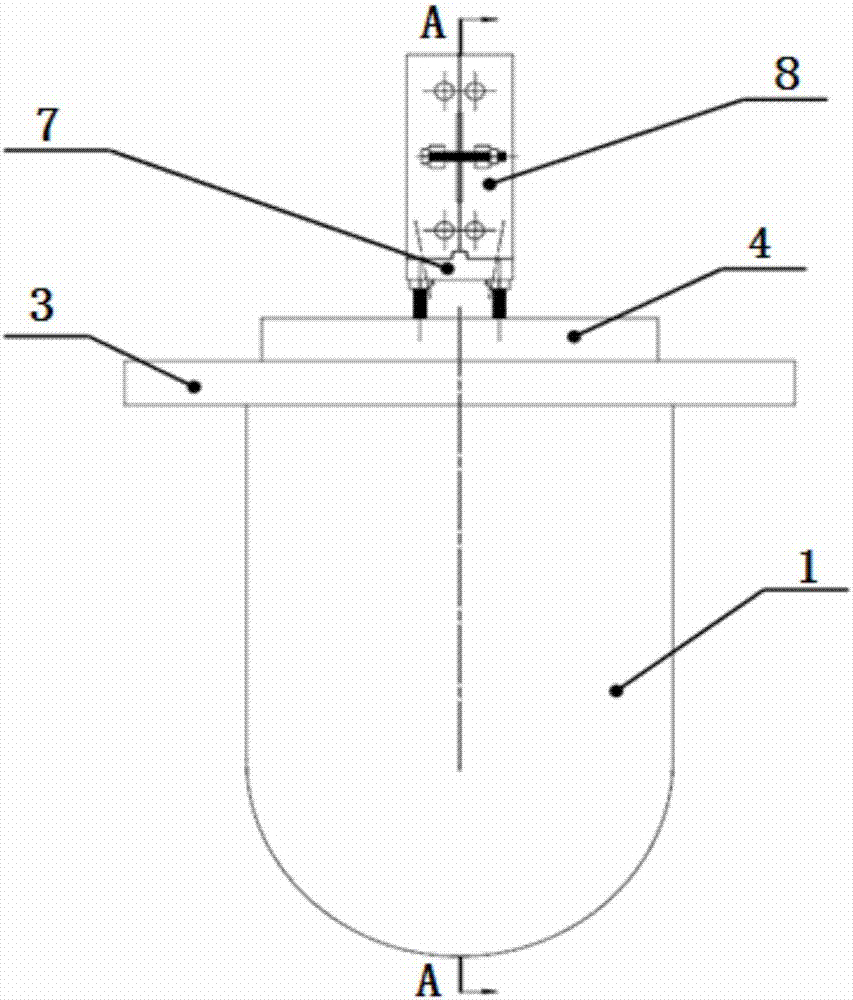

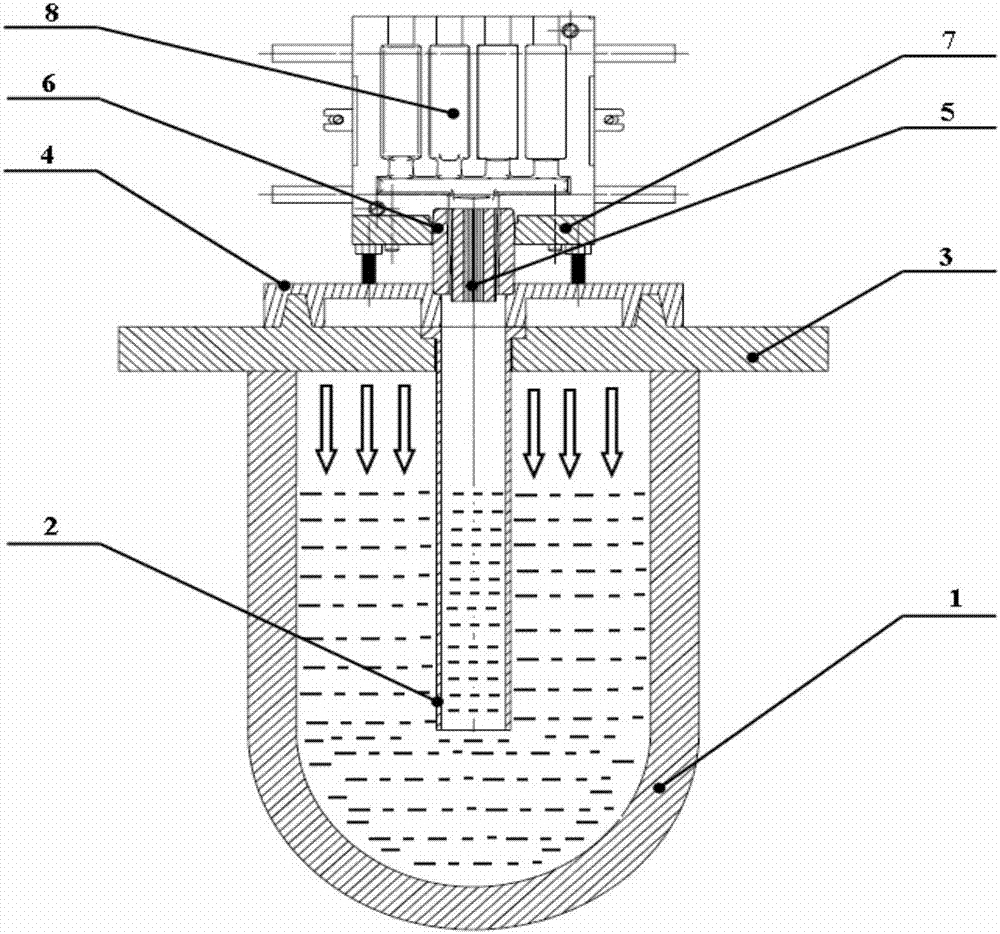

Method used

Image

Examples

Embodiment 1

[0043] This implementation example is a semi-solid low-pressure rheologically formed ZL101A alloy casting. The composition of the alloy material is (weight percent) Si: 6.96%, Mg: 0.35%, Ti: 0.15%, Fe: 0.1%, Ni: 0.01%, Zn : 0.01%, Cu: 0.01%, Mn: 0.01%, Sn: 0.01%, and the rest is Al. The liquidus and solidus temperatures of the ZL101A alloy are 615°C and 560°C, respectively.

[0044] The specific process is as follows:

[0045] 1) Melt the ZL101A aluminum alloy in the crucible resistance furnace 1, and when the temperature of the alloy reaches about 680°C, add a modifying agent, and then add argon for refining after the modification is completed (the amount added is 0.5% of the total weight of the alloy liquid), and the argon The gas is pressed into the bottom of the light alloy liquid with a bell jar and gently swings to make the ZL101A aluminum alloy liquid boil completely. When there are no more bubbles in the bell jar, clean the slag with a scum spoon, and finally lower t...

Embodiment 2

[0049] This implementation example is a semi-solid low-pressure rheologically formed ZL114A alloy casting. The composition of the alloy material is (weight percent) Si: 6.96%, Mg: 0.55%, Ti: 0.15%, Fe: 0.1%, Ni: 0.01%, Zn : 0.01%, Cu: 0.01%, Mn: 0.01%, Sn: 0.01%, and the rest is Al. The liquidus and solidus temperatures of the ZL114A alloy are 615°C and 560°C, respectively.

[0050] The specific process is as follows:

[0051] 1) Melt the ZL114A aluminum alloy in the crucible resistance furnace 1. When the gold temperature reaches about 685°C, add a modifying agent. After the modification is completed, add argon for refining (the amount added is 0.5% of the total weight of the alloy liquid). Argon The gas is pressed into the bottom of the light alloy liquid with a bell jar and gently swings to make the aluminum alloy liquid boil completely. When there are no more bubbles in the bell jar, clean the slag with a scum spoon, and finally lower the temperature of the alloy liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com