Control method for switching working points of range extender

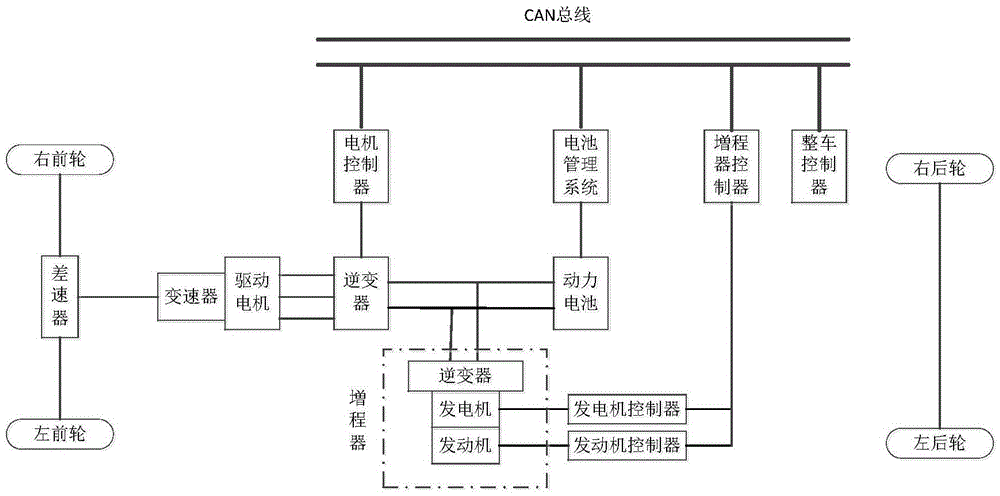

A control method and a technology of a range extender, which are used in transportation and packaging, motor vehicles, hybrid vehicles, etc., can solve problems such as increasing the complexity of the structure, and achieve the reduction of working noise, simplification of the structure, and reduction of rotational speed overshoot. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Vehicle status data at the current moment:

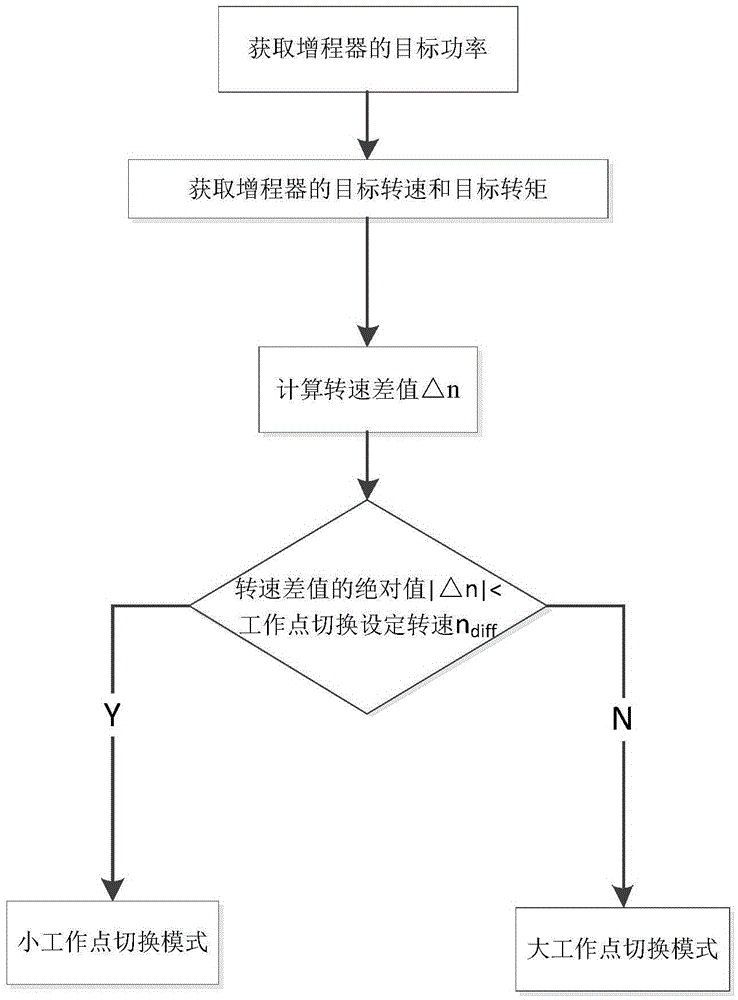

[0083] Take the target power P of the range extender target is 30Kw, the current actual speed of the range extender n act It is 2400rpm, and the working point is switched to set the speed n diff 300rpm.

[0084] The judgment steps are as follows:

[0085] Step 1. Obtain the target power P of the range extender target ;

[0086] The range extender controller obtains the target power of the range extender as 30Kw through CAN bus signal transmission according to the control requirements of the vehicle controller;

[0087] Step 2. Obtain the target speed n of the range extender target and target torque T target ;

[0088] According to the optimal fuel consumption rate curve of a certain engine, the target power 30Kw on the engine’s optimal fuel consumption rate curve corresponds to a speed of 2500rpm and a torque of 114.6Nm, which are respectively taken as the target speed n of the range extender target and target torque...

Embodiment 2

[0097] Vehicle status data at the current moment:

[0098] Take the target power P of the range extender target is 37Kw, the current actual speed n of the range extender act It is 2400rpm, and the working point is switched to set the speed n diff 300rpm.

[0099] The judgment steps are as follows:

[0100] Step 1. Obtain the target power P of the range extender target ;

[0101] The range extender controller obtains the target power of the range extender as 30Kw through CAN bus signal transmission according to the control requirements of the vehicle controller;

[0102] Step 2. Obtain the target speed n of the range extender target and target torque T target ;

[0103] According to the optimal fuel consumption rate curve of a certain engine, the target power 37Kw on the engine’s optimal fuel consumption rate curve corresponds to a speed of 3000rpm and a torque of 117.8Nm, which are respectively taken as the target speed n of the range extender target and target torque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com