pump device

A pump device and technology for generating devices, which are applied in the directions of pumps, components of pumping devices for elastic fluids, pump elements, etc., can solve problems such as expensive devices and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

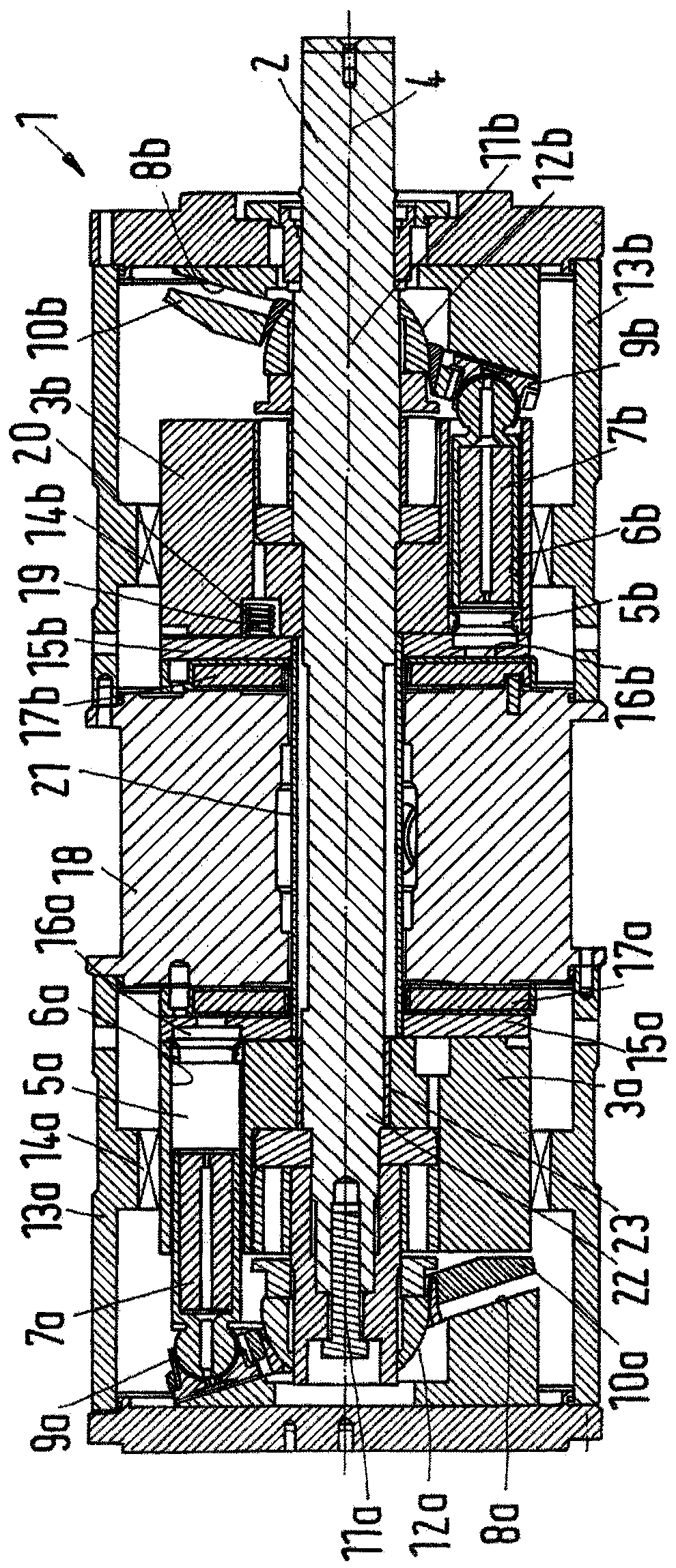

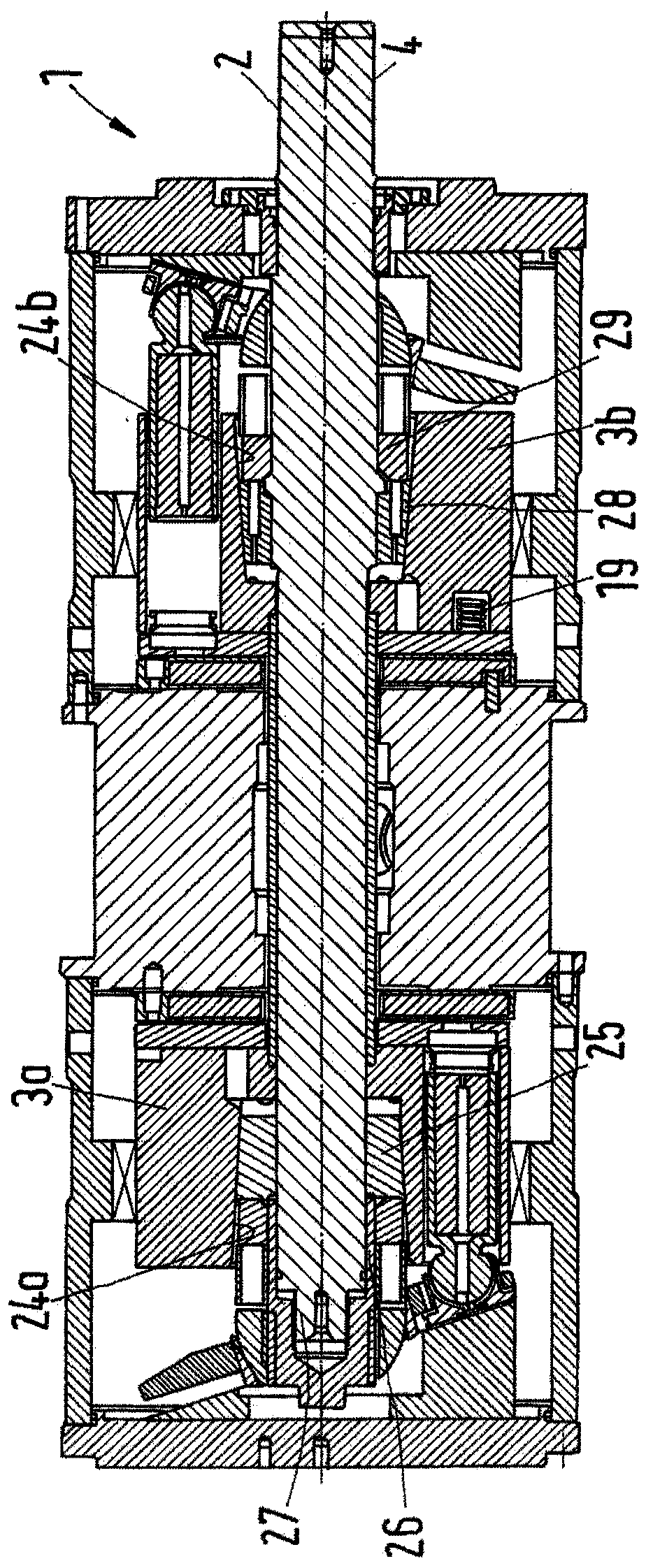

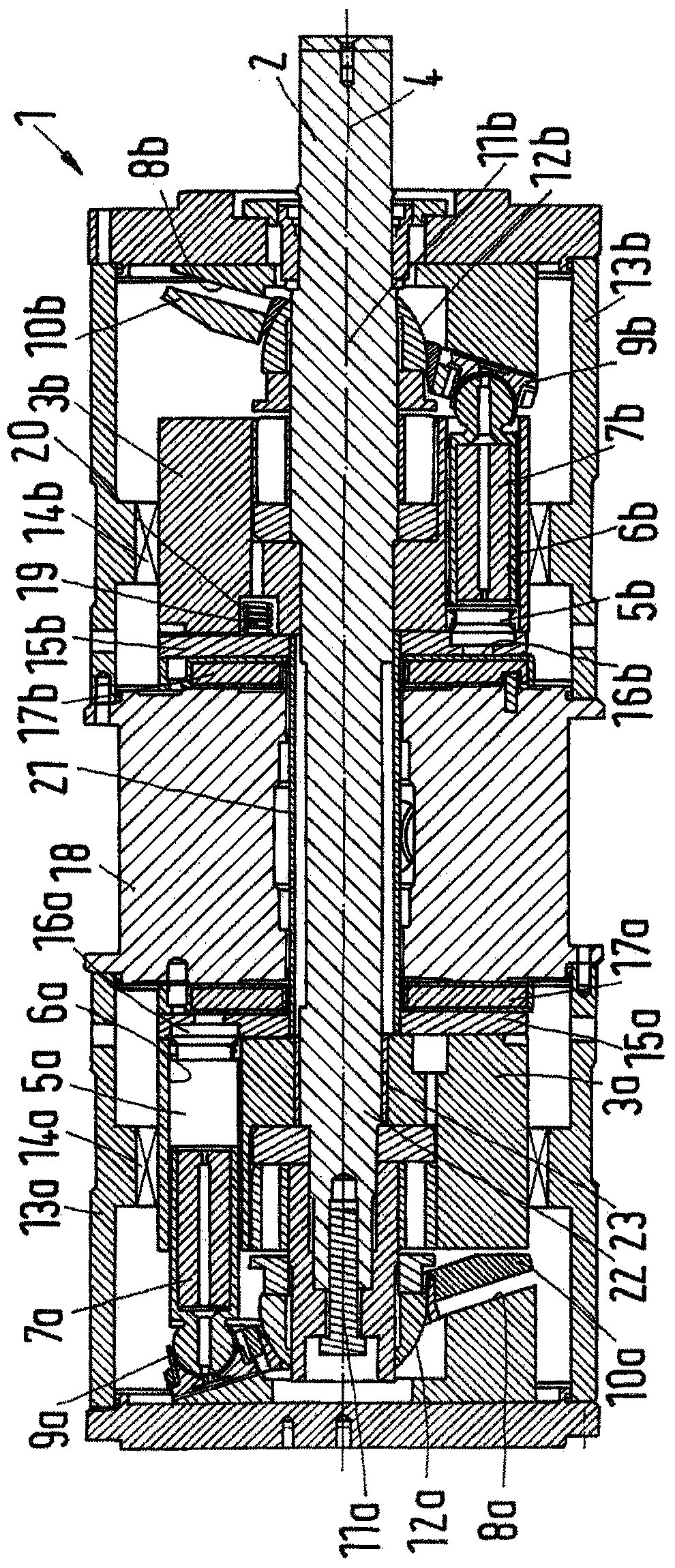

[0025] The pump device 1 is used to pump water. It is a water hydraulic machine and comprises a shaft 2 which is rotatable by a motor not shown. The shaft 2 is a through-shaft extending almost the entire length of the pump device 1 . The first rotor 3 a and the second rotor 3 b are fixed to the shaft 2 in the direction of rotation and in the axial direction of the shaft 2 , which refers to the axis of rotation 4 of the shaft 2 .

[0026] The first rotor 3a has a plurality of first pressure chambers 5a. Each pressure chamber 5a is formed by a first cylinder 6a and a first piston 7a which is movable parallel to the axis 4 of the shaft 2 during operation. Thus, the volume of the first pressure chamber 5 a changes between a maximum size and a minimum size during the rotation of the shaft 2 .

[0027] The first swash plate 8a is positioned facing the front of the first rotor 3a. Each first piston 7a is provided with a first slide 9a. The slider 9a is held in contact with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com