Collision detection method and system for three-dimensional model

A collision detection and 3D model technology, applied in the field of computer data processing, can solve problems such as insufficient detection accuracy, failure to detect support coverage, and affect printing, etc., to improve collision detection accuracy, simplify algorithm complexity, and improve detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

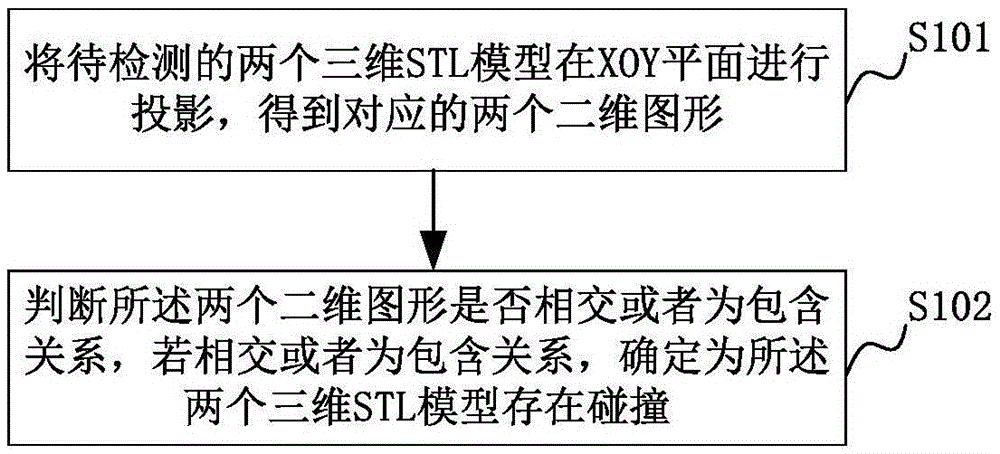

[0060] figure 2 It is a schematic flow chart of the collision detection method of the three-dimensional model according to the first embodiment. like figure 2 As shown in , the collision detection method of the three-dimensional model of the present embodiment includes the following steps S101 and S102, which are described in detail as follows:

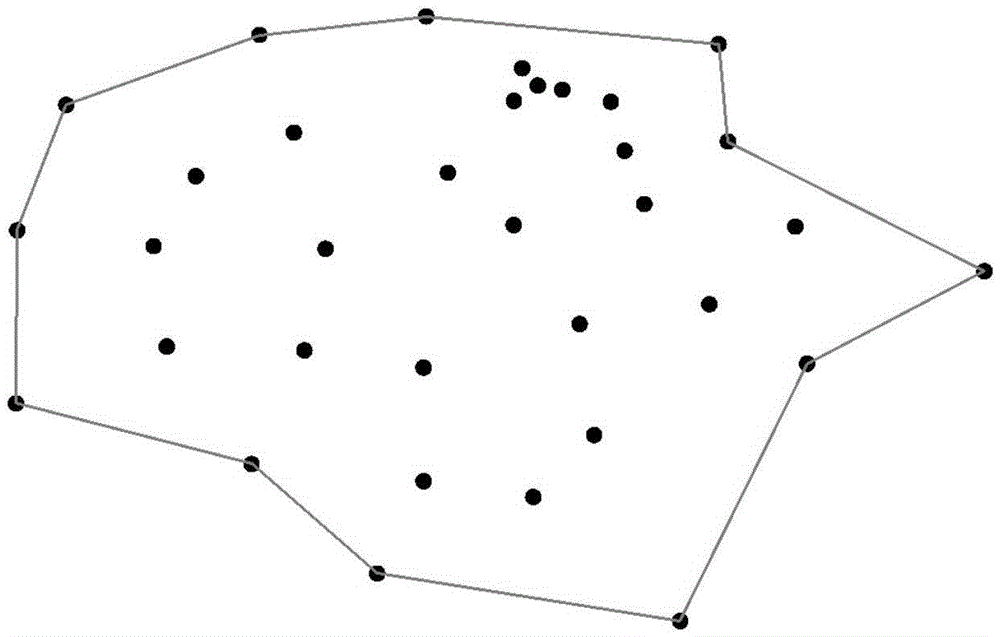

[0061] S101, project the two three-dimensional STL models to be detected on the XOY plane to obtain two corresponding two-dimensional graphics;

[0062] In this embodiment, STL is a standard file type applied by the rapid prototyping system, the STL model can only be used to represent closed surfaces or volumes, and the three-dimensional STL model refers to the use of triangular meshes to represent the 3DCAD model.

[0063] The XOY plane refers to a two-dimensional plane based on the X, Y coordinate system, and the O point identifies the origin of the X, Y coordinate system. The two three-dimensional STL models to be detected are...

Embodiment 2

[0091] Figure 4 It is a schematic flow chart of the collision detection method of the three-dimensional model of the second embodiment. The main differences between the second embodiment and the above-mentioned first embodiment include: for the additive manufacturing including the support structure, since the three-dimensional models are placed relatively compactly in the space, even if the two-dimensional projections of multiple three-dimensional models neither intersect nor contain relationship, there is still the possibility of collision. Therefore, on the basis of the first embodiment, this embodiment also adds a distance limit to further improve the accuracy of the collision detection of the three-dimensional model.

[0092] like Figure 4 As shown in , the collision detection method of the three-dimensional model of the present embodiment includes the following steps S201 to S207, which are described in detail as follows:

[0093] S201, project the two three-dimensio...

Embodiment 3

[0113] Figure 7 It is a schematic structural diagram of the collision detection system of the three-dimensional model of the third embodiment, such as Figure 7 As shown, the collision detection system of the three-dimensional model of this embodiment includes: a projection module 100 and a first detection module 200 . in:

[0114] The projection module 100 is used for projecting the two three-dimensional STL models to be detected on the XOY plane to obtain two corresponding two-dimensional graphics; the specific implementation process refers to the above-mentioned implementation, and will not be repeated.

[0115] The first detection module 200 is configured to determine whether the two two-dimensional graphics intersect or are in an inclusive relationship, and if they intersect or are in an inclusive relationship, it is determined that the two three-dimensional STL models collide.

[0116] Preferably, the first detection module 100 may specifically include:

[0117] an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com