A kind of quick card type wiring harness connection terminal

A technology of connecting terminals and fast card type, which is applied in the field of wire harnesses, can solve the problems of easy breakage, large amount of consumables, and small terminal pulling force, and achieve the effect of not easy to break, not easy to release, and save materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

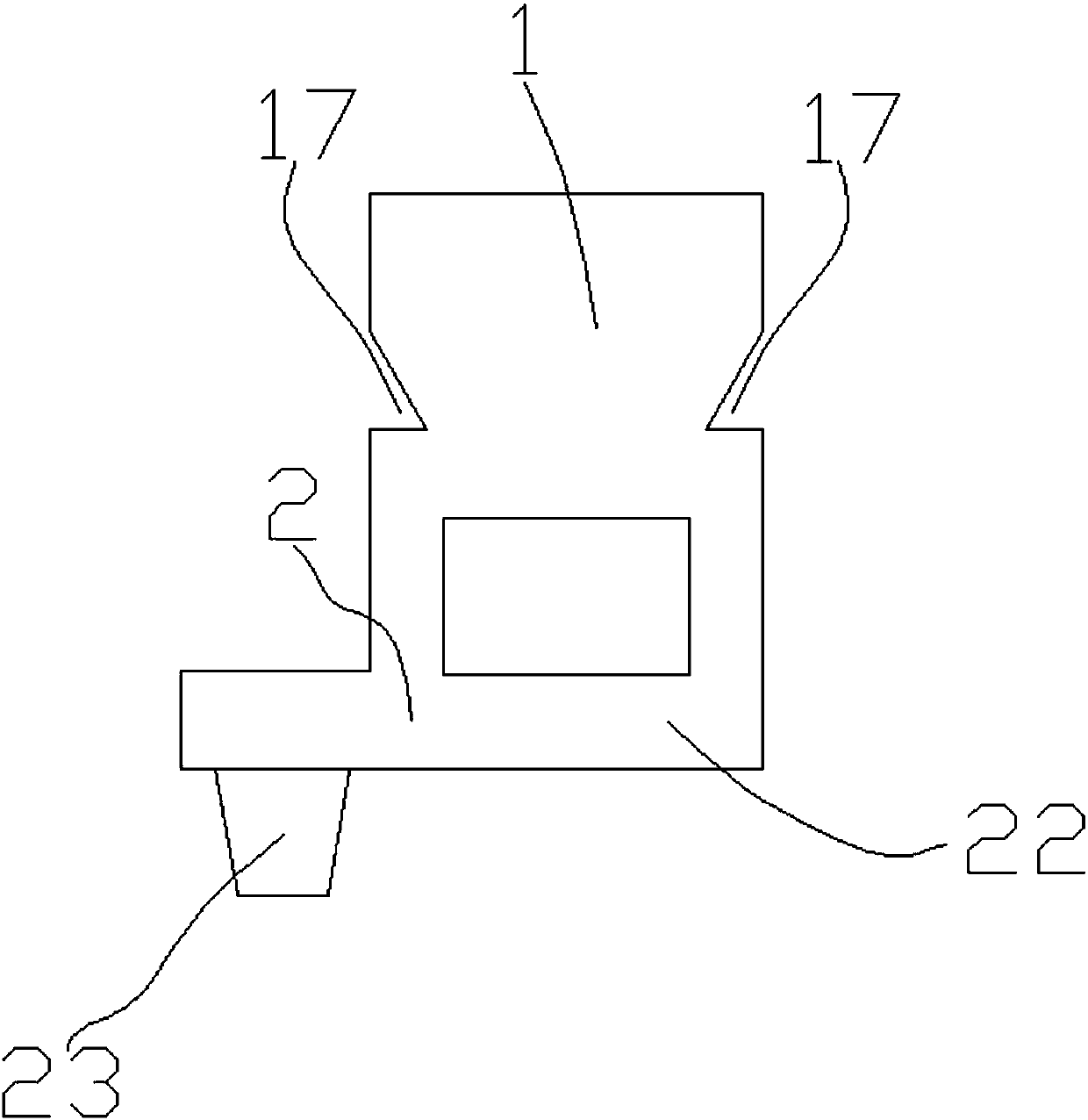

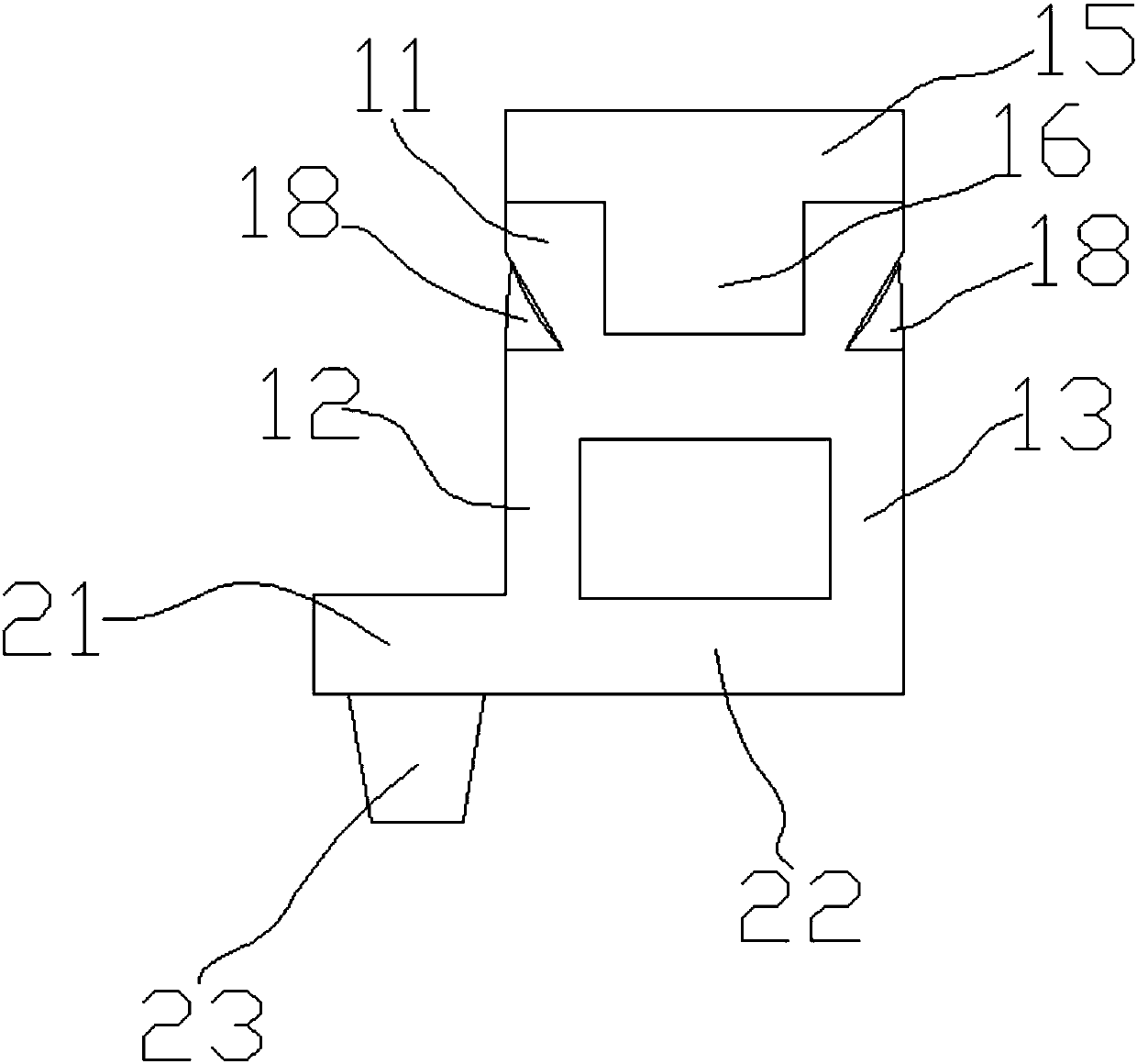

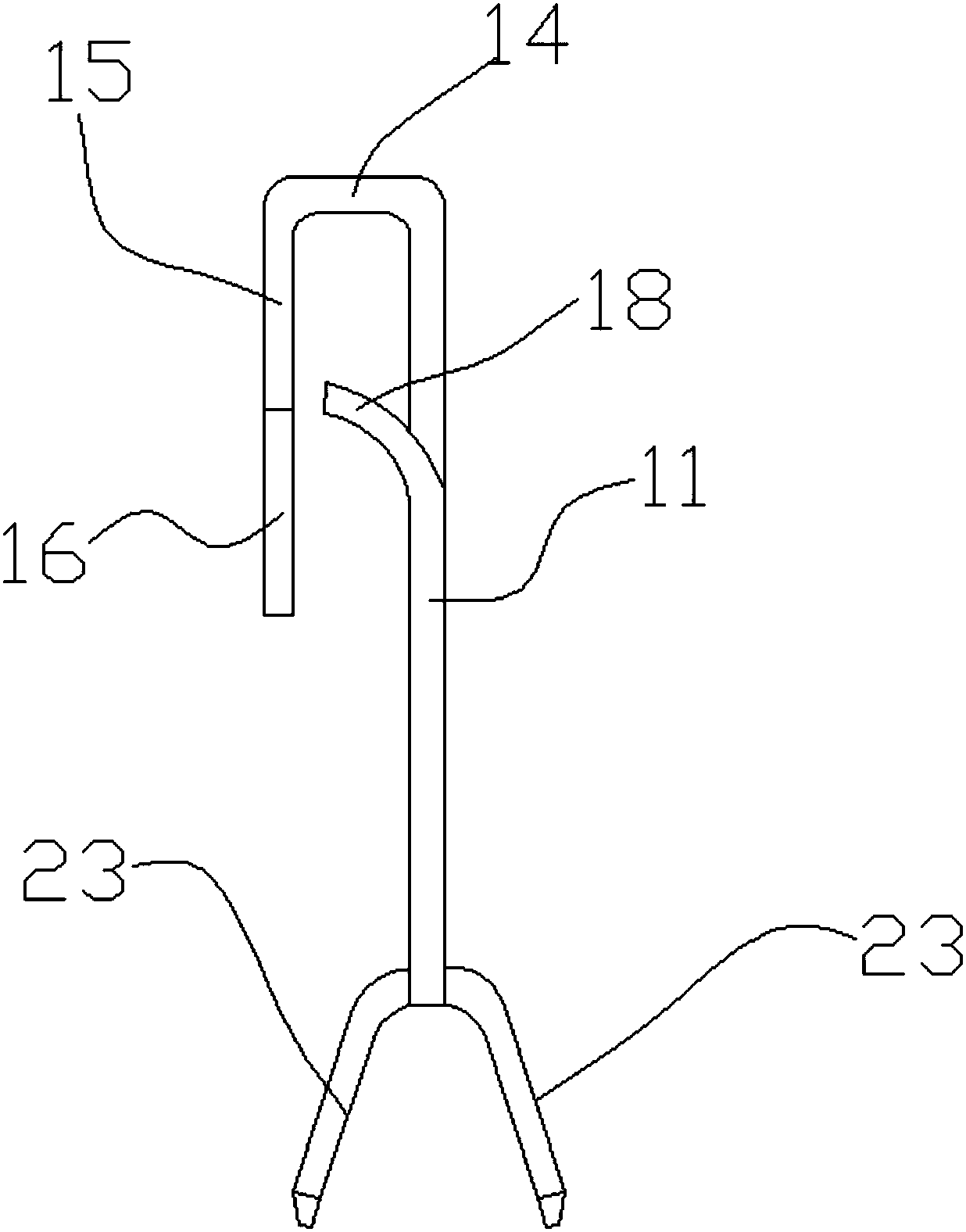

[0023] like figure 1 , figure 2 and image 3 As shown, a quick clip-type wire harness connection terminal includes a terminal body, and the terminal body is composed of a clip-type part 1 and a wire harness connection part 2. The clip-type part 1 includes a clip-type base part 11, and the clip-type base part 11 The left side and the right side of one end protrude outward respectively to form a left connecting part 12 and a right connecting part 13, wherein the other ends of the left connecting part 12 and the right connecting part 13 are connected to the wire harness connecting part 2, and the snap-in The root of the other end of the base portion 11 is bent to form a transition portion 14 , the root of the other end of the transition portion 14 is bent to form a plug-in connection portion 15 , and the other end of the plug-in connection portion 15 protrudes outward to form a plug-in portion 16 , The left and right sides of the card-type base 11 are provided with protective ...

Embodiment 2

[0025] like Figure 4 , Figure 5 and Figure 6 As shown, a quick clip-type wire harness connection terminal includes a terminal body, and the terminal body is composed of a clip-type part 1 and a wire harness connection part 2. The clip-type part 1 includes a clip-type base part 11, and the clip-type base part 11 The left side and the right side of one end protrude outward respectively to form a left connecting part 12 and a right connecting part 13, wherein the other ends of the left connecting part 12 and the right connecting part 13 are connected to the wire harness connecting part 2, and the snap-in The root of the other end of the base portion 11 is bent to form a transition portion 14 , the root of the other end of the transition portion 14 is bent to form a plug-in connection portion 15 , and the other end of the plug-in connection portion 15 protrudes outward to form a plug-in portion 16 , The left and right sides of the card-type base 11 are provided with protectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com