A multi-wavelength pumped temperature-free solid-state laser and multi-wavelength selection method

A solid-state laser and multi-wavelength technology, applied in the laser field, achieves the effects of stable absorption conversion efficiency, insensitivity to environmental temperature changes, and stable laser power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

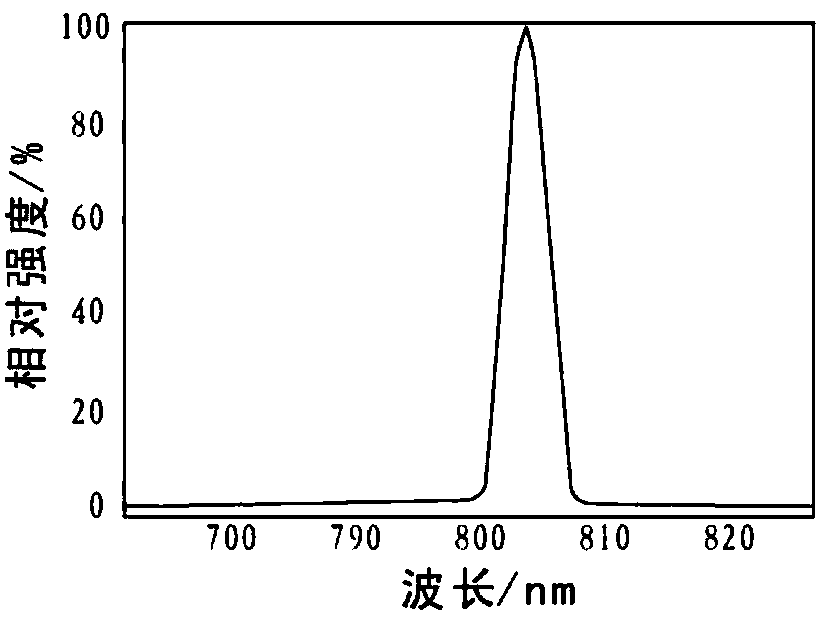

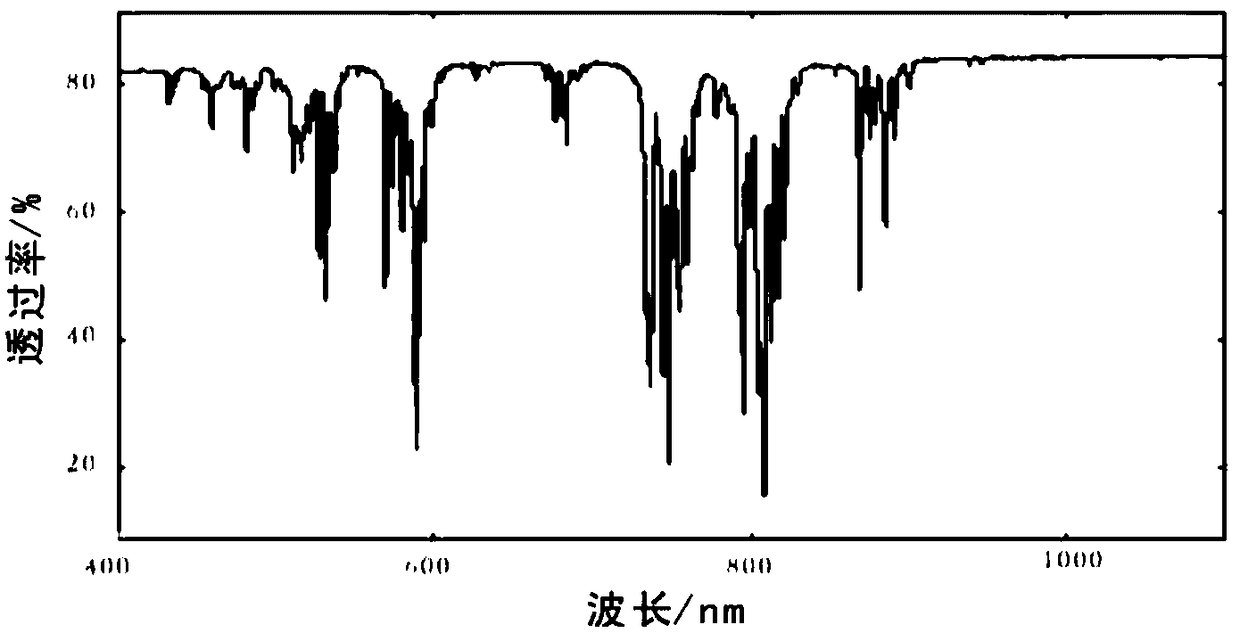

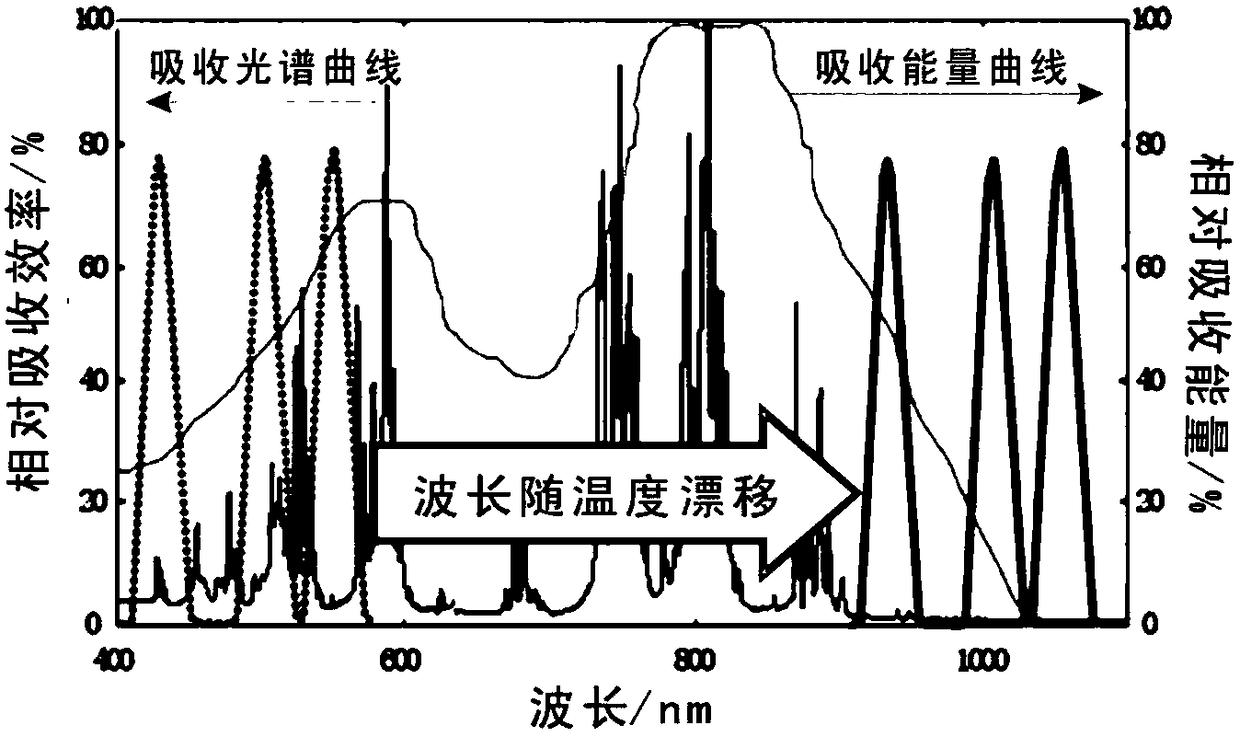

[0040] Embodiments of the present invention are described with reference to the accompanying drawings. The laser includes a pump source LD array heat sink 1, a multi-wavelength LD array 2, a pump light shaping mirror 3, a pump light coupling mirror 4, a 1064nm total reflection mirror 5, and an end-face bonding Pure YAG6, Nd:YAG laser gain medium7, Q-switching system8 and 1064nm output mirror9. The multi-wavelength LD array 2 is packaged on the pump source LD array heat sink 1 in the package form of G-Stack, and emits multi-wavelength pump light when the laser is working (the multi-wavelength selection method of the multi-wavelength LD array 2 will be described in details in the examples that follow). The light-emitting surface of the multi-wavelength LD array 2 is aligned with the incident end faces of the pump light shaping mirror 3 and the pump light coupling mirror 4. After the multi-wavelength pump light is shaped by the pump light shaping mirror 3, it passes through the p...

Embodiment 2

[0078] According to the method of Embodiment 1, the doping concentration of the Nd:YAG laser gain medium 7 is set to 0.65%, and the absorption lengths are respectively 50 mm and 30 mm. If the multi-wavelength LD array 2 is composed of three wavelengths, the wavelength selection program is set to take one wavelength as a reference, and it varies within the range of 780nm to 830nm, and the variation range of the other two wavelengths is within ±20nm of the reference wavelength. The energy range varies between 0.6 and 1. For the gain medium with an absorption length of 50mm, the set temperature-free temperature range should be greater than 70°C, and for the gain medium with an absorption length of 30mm, the set temperature-free temperature range should be greater than 50°C. The program calculates the laser output energy E according to formula (6) 0 , calculate the absorption efficiency ε according to the formula (4), select the wavelength combination whose pump light absorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com