White light-emitting diode and preparation method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of white light color temperature rise, etc., and achieve the effects of less saturation and high absorption and conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The white light emitting diode of the present invention and its manufacturing method are described in detail below in conjunction with schematic diagrams, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention.

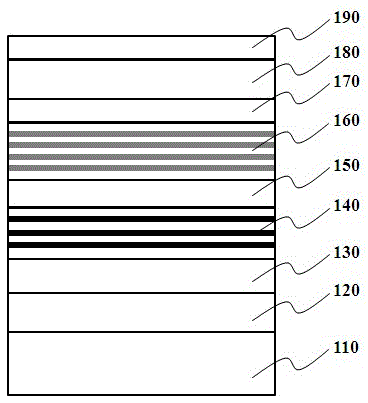

[0026] see figure 1 , the epitaxial structure of the white light emitting diode in the first preferred embodiment of the present invention, including from bottom to top: substrate 110, non-doped nitride layer 120, n-type nitride layer (ie electron injection layer) 130, yellow Optical quantum well 140 , n-type barrier layer 150 , active layer 160 , p-type barrier layer 170 , p-type nitride layer 180 (ie hole injection layer) and p-type contact layer 190 . Wherein, the emission wavelength of the active layer 160 is 435nm-465nm, and the emission peak wavelength corresponding to the quantum well 140 is 550-580nm.

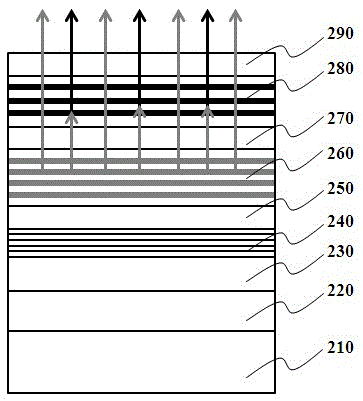

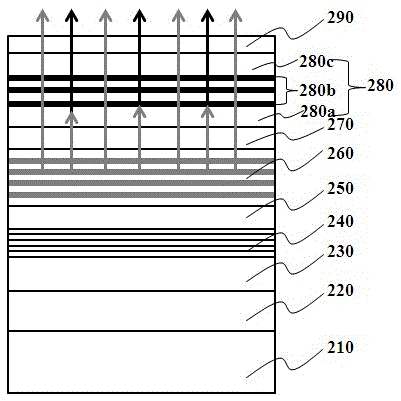

[0027] see figure 2 ,for figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com