Two-pack epoxy resin composition for fiber-reinforced composite material, and the fiber-reinforced composite material

A resin composition and epoxy resin technology, applied in the field of two-component epoxy resin composition, can solve the problems of insufficient resin rigidity, reduced dimensional accuracy, insufficient high-speed curability, etc., and achieve excellent viscosity stability, Excellent operability and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

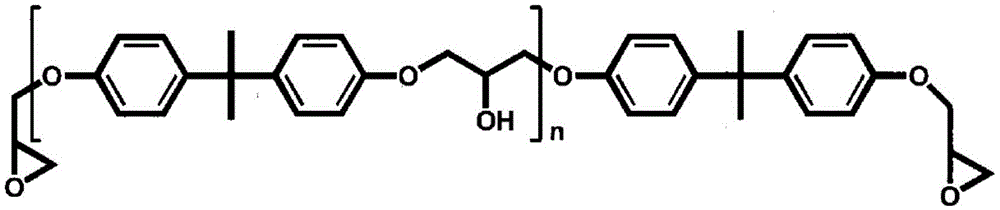

Method used

Image

Examples

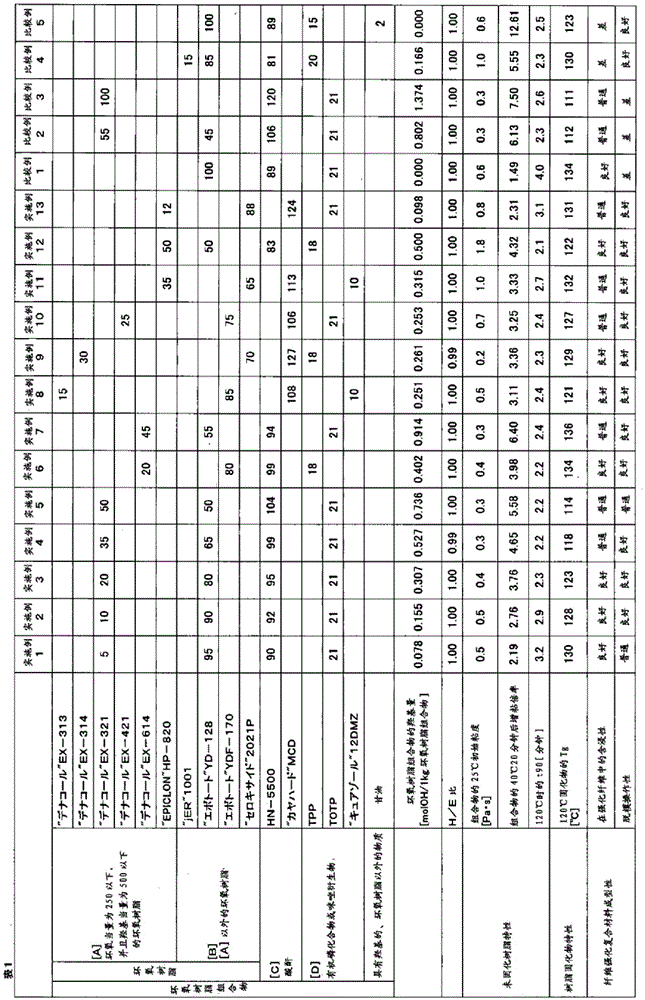

Embodiment 1~13

[0164] As mentioned above, an epoxy resin composition was prepared, and viscosity measurement and dielectric measurement were performed. Furthermore, using the prepared epoxy resin composition, a resin-cured board and a fiber-reinforced composite material were manufactured as described above.

[0165] As shown in Table 1, even when the epoxy resin composition of the present invention is kept at a low temperature of 40° C., the thickening ratio is suppressed low, and a low viscosity state is maintained. In addition, it can be seen that shortening the molding time is also effective in molding fiber-reinforced composite materials because the demoulding time represented by t90 at 120° C. is short. In addition, since the Tg of the cured resin exceeds the molding temperature (120° C.), when the molded product is taken out from the mold, it can be easily demolded without deformation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com