Compressor with variable compressor inlet

A technology for compressors and compressor housings, applied in the direction of machines/engines, mechanical equipment, non-variable pumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

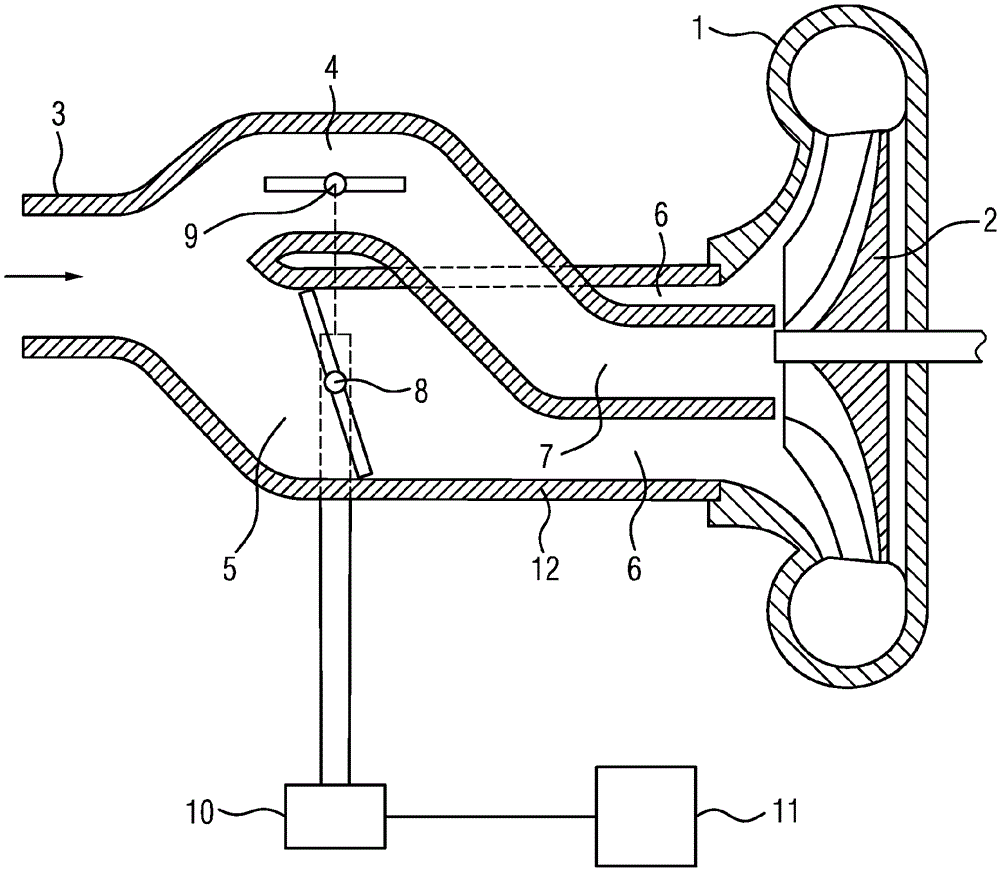

[0020] In the corresponding schematic sectional illustration, the compressor housing 1 with the associated compressor inlet 12 is shown. A compressor wheel 2 with corresponding compressor blades (indicated only schematically) is located in the compressor housing 1 . Air flows from an air intake filter (not shown) into header 3 and from there into compressor inlet 12 . Adjacent to the header 3, the compressor inlet 12 has two separate tubes 4, 5 arranged adjacent to each other into which the header 3 merges. The upper tube 4 shown in the figure extends into the lower tube 5 and thus forms two concentric tubes (ie inner tube 7 and outer tube 6 ) and is adjacent to the compressor housing 1 in the region of the compressor inlet 12 . In this case, the inner tube 7 is directed towards the radially inner region and the outer tube 6 is directed towards the radially outer region of the compressor blade. In terms of cross section, the inner tube 7 has a circular air passage section, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com