Vertical three-dimensional pruning machine for tea gardens

A pruning machine and tea garden technology, applied in gardening, electric pruning saws, gardening tools/equipment, etc., can solve the problems of heavy workload, low production efficiency, and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

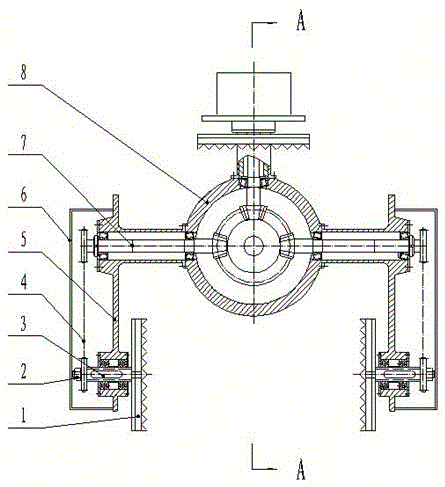

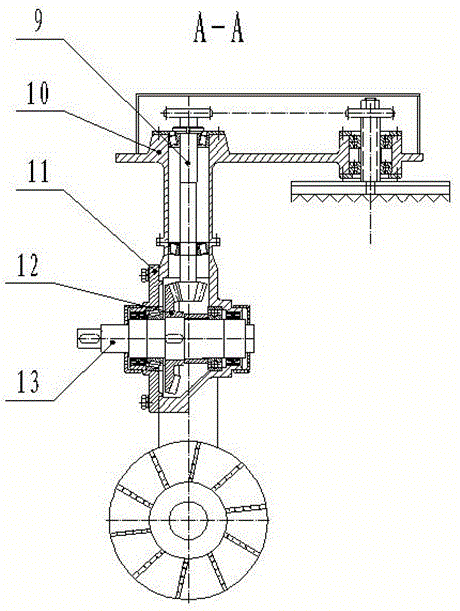

[0012] In the embodiment shown in the accompanying drawings, the present invention consists of trimming knife (1), wheelbase adjustment mechanism (2), trimming shaft (3), sprocket chain mechanism (4), side frame (5), protective cover (6), side shaft gear (7), machine base (8), elevation shaft gear (9), elevation frame (10), bearing cover (11), bevel gear (12), and main shaft (13) , the main shaft (13) is installed on the machine base (8) with bearings, arranged horizontally, the bevel gear (12) is installed on the main shaft (13) and connected by a key, and the bearing cover (11) is connected to the bottom of the machine base (8) The end face is used to fix and repair the bearing and the main shaft (13). The side frame (5) is connected with the machine base (8) by bolts, and is divided into one left and one each. The side shaft gear (7) is installed on the side frame ( 5) Inside, the side shaft gear (7) meshes with the bevel gear (12), one on each side symmetrically arranged, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com