Denitration reductant adding control method based on time difference matching and control device of control method

A control method and reducing agent technology, applied in the direction of separation methods, chemical instruments and methods, gas treatment, etc., can solve the problem that the change of reducing agent addition cannot be matched and controlled in time, and achieve the effects of reducing adverse effects, easy implementation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

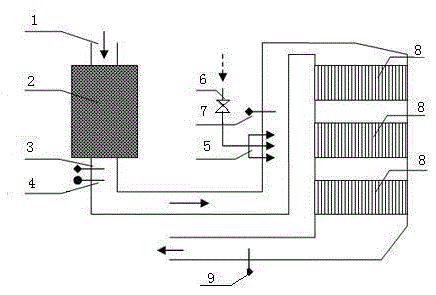

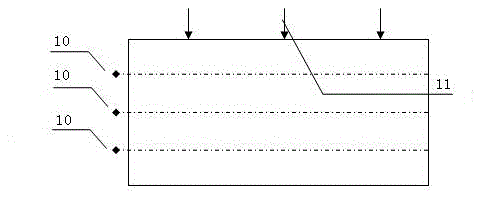

[0025] Such as figure 1 As shown, a control device based on a time difference matching denitrification reducing agent addition control method includes a flue gas pipeline 1, an economizer heat exchange device 2 and a catalyst layer 8, and the economizer heat exchange device 2 and catalyst layer 8 The flue gas pipeline 1 is sequentially divided into an intake flue gas pipeline 1-1, a denitrification flue gas pipeline 1-2, and an outlet flue gas pipeline 1-3. Flue gas analysis test point A3, flue gas velocity and flow rate test point 4, ammonia injection grid 5 and in-situ online flue gas analysis test point B7, the ammonia injection grid 5 is connected to the regulating valve 6 for controlling the amount of ammonia added , The online flue gas analysis test point D9 is set on the outlet flue gas pipeline 1-3.

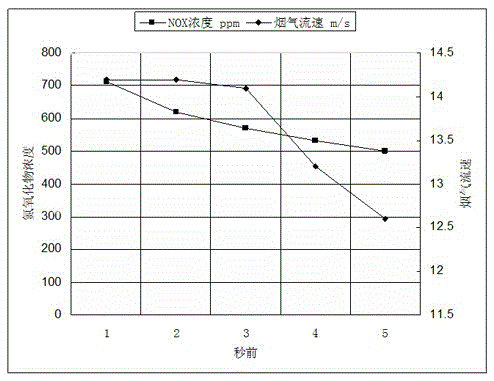

[0026] (1) The hot flue gas discharged from the boiler furnace or the hot flue gas is cooled by the economizer heat exchange device 2, and an in-situ online flue gas ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com