Full-automatic bender for medical suture needles

A fully automatic, bending machine technology, applied in the field of medical equipment automatic production equipment, can solve the problems of hidden safety hazards, high randomness, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

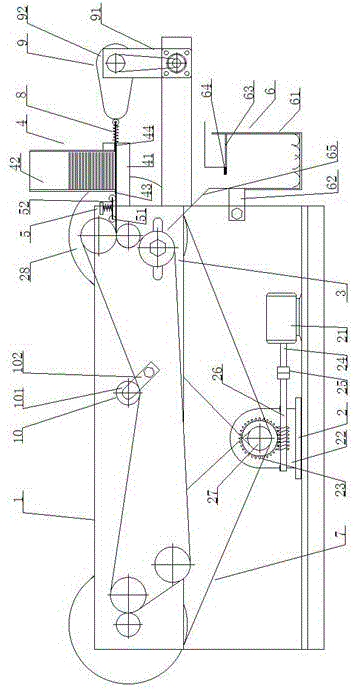

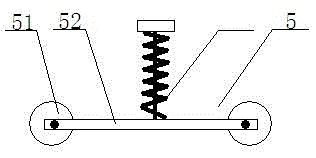

[0031] Such as figure 1 , 2 , 3, the present invention includes a frame body 1, and the frame body 1 is provided with a power drive device 2, a bending device 3, an automatic feeding device 4 and a plane correction device 5;

[0032] Described power drive device 2 comprises driving motor 21, transmission gear box 22 and driving wheel 23, and driving motor 21 power output shaft 24 is connected with driving screw rod 26 by coupling 25, and driving screw rod 26 drives the transmission wheel 27 of transmission gear box 22 , the driving wheel 27 drives the driving wheel 28 to rotate through the transmission device 7;

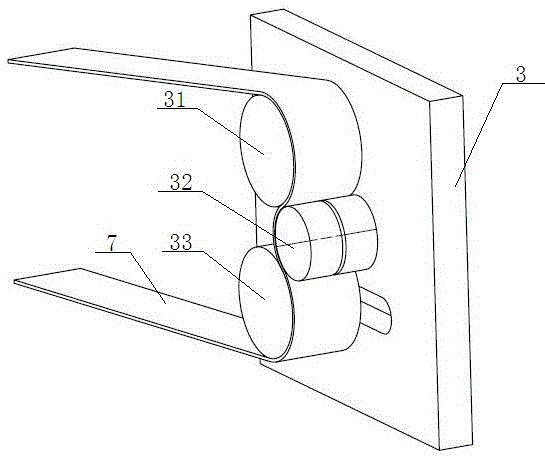

[0033] Described bending device 3 comprises power wheel 31, forming wheel 32 and adjustment wheel 33, and forming wheel 32 is positioned between power wheel 3 and adjustment wheel 33, and forming wheel 32 wheel diameters are smaller than power wheel 3 and adjustment wheel 33, and power wheel 31 , the forming wheel 32, and the adjusting wheel 33 are connected by tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com