New energy automobile charger

A new energy vehicle and charging device technology, applied in electric vehicle charging technology, charging stations, electric vehicles, etc., can solve the problems of difficult adaptation of the linkage mechanism and difficult bending of the mechanical arm, and achieve a high degree of automation and a large bending range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

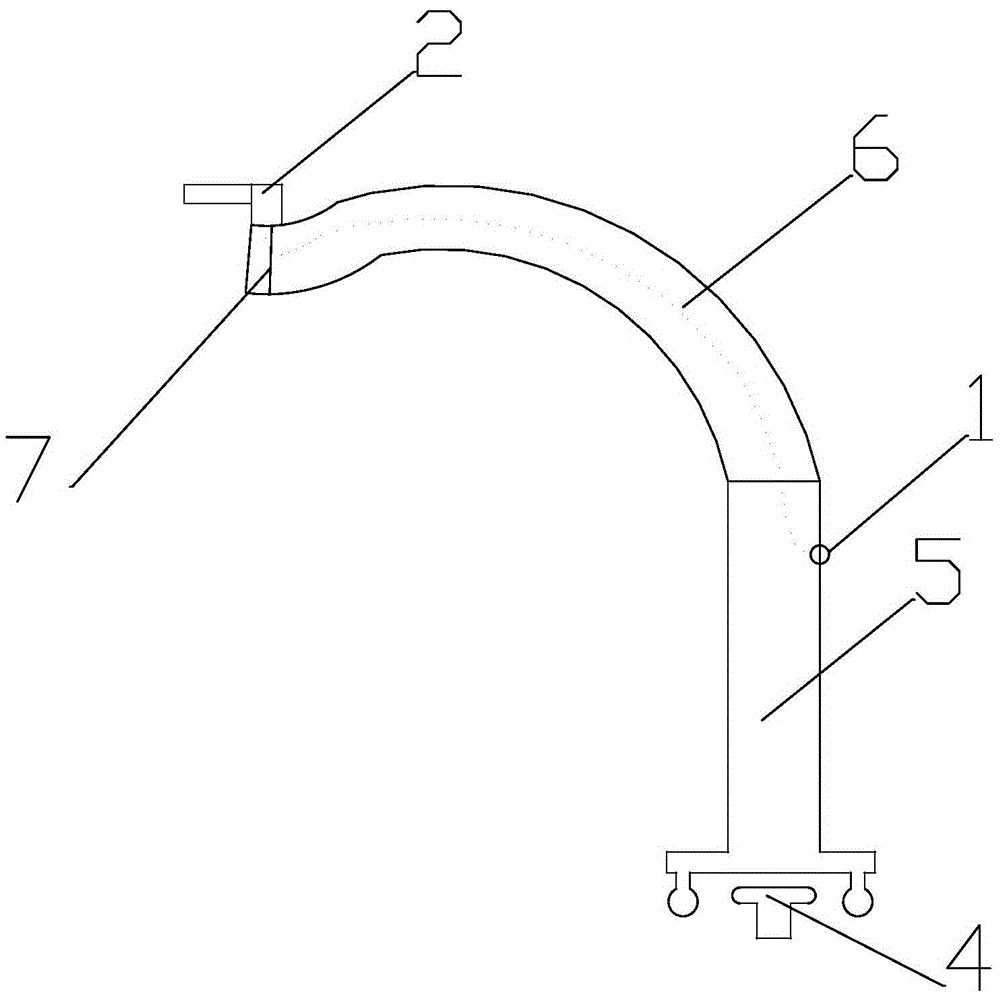

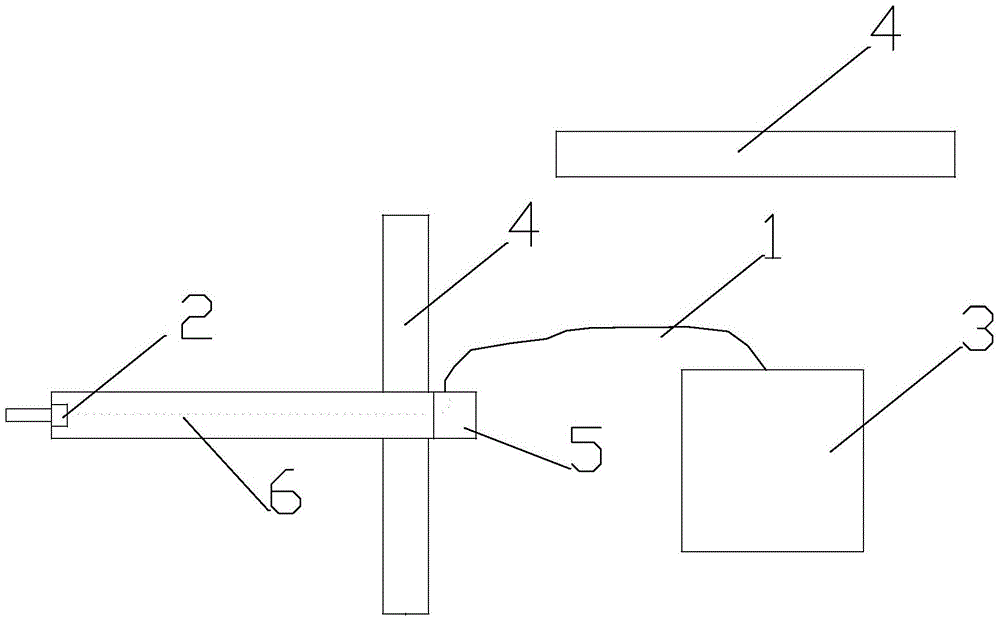

[0015] Embodiment: The present invention includes a charging pile 3 and a charging gun 2 connected to the charging pile 3 through a charging line 1, and also includes a mechanical arm 6, a guide rail 4 matched with the charging pile 3, and a walking trolley 5 located on the guide rail 4. One end of the mechanical arm 6 is installed on the walking trolley 5 , and the charging gun 2 is installed on the other end of the mechanical arm 6 . The guide rail 4 is arranged parallel to one side of the charging pile 3 or vertically arranged on one side of the charging pile 3 . The mechanical arm 6 is provided with an image recognition sensor 7 for identifying the socket of the new energy vehicle and the charging gun, wherein the charging line 1 can be installed on the walking trolley 5 through the crawler.

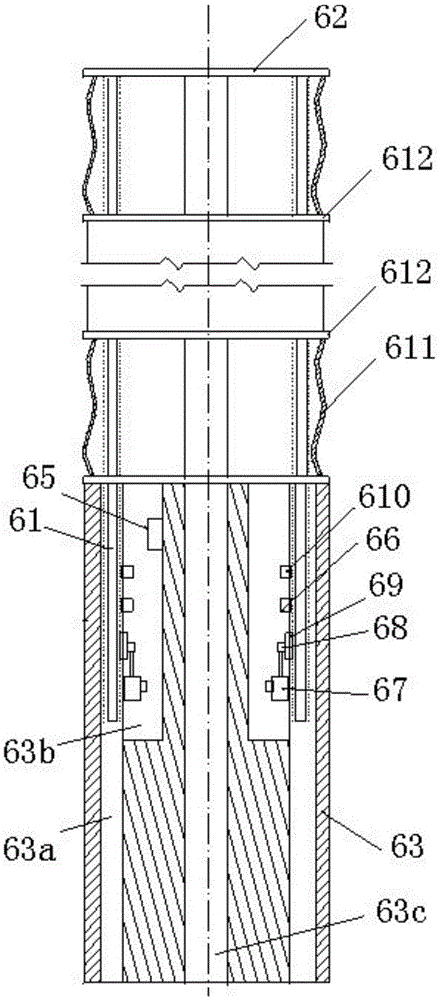

[0016] The mechanical arm 6 includes a screw 61 and at least one joint, the screw 61 is at least three, and the joint includes a head module 62 and a base 63 provided with a guide ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com